High-strength heat-resistant flame-retardant ABS alloy material

An alloy material, high-strength technology, applied in the field of high-strength, heat-resistant, flame-retardant ABS alloy materials, can solve the problems of ABS resin losing high gloss, unsuitable for promotion and application, reducing the toughness and fluidity of flame-retardant ABS, and achieving enhanced Remarkable effect, good flame retardant performance, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

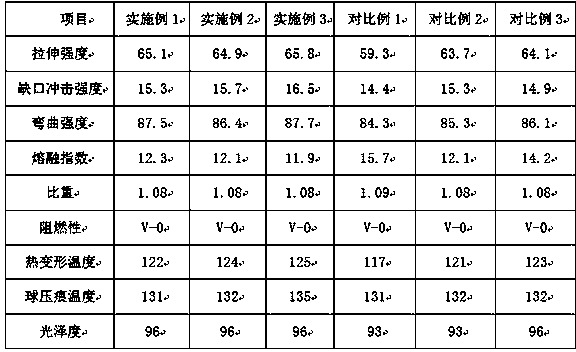

Embodiment 1

[0026] A high-strength heat-resistant and flame-retardant ABS alloy material comprises the following component raw materials in parts by weight:

[0027] 100 parts of high heat-resistant ABS particles, 23 parts of polyphenylene ether, 17 parts of PET, 8 parts of resorcinol diphenylphosphate, 1.5 parts of MAH-g-SEBS, 2.3 parts of SAN-g-GMA, 4 parts of dispersant parts, 11 parts of glass fiber, 0.6 parts of antioxidant, 0.6 parts of light stabilizer, 3.7 parts of processing aid, and 7 parts of flame retardant.

[0028] Further, it is characterized in that the high heat-resistant ABS particles are modified by a heat-resistant modifier, and the heat-resistant modifier is N-isopropylmaleimide, N-cyclohexylmaleimide One or more of imide, N-phenylmaleimide, styrene-N-phenylmaleimide-maleic anhydride copolymer, SMA and diphenylmethane bismaleimide mixture of species.

[0029] Further, the antioxidant is composed of tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaeryt...

Embodiment 2

[0038] A high-strength heat-resistant and flame-retardant ABS alloy material comprises the following component raw materials in parts by weight:

[0039] 100 parts of high heat-resistant ABS particles, 41 parts of polyphenylene ether, 19 parts of PET, 9 parts of resorcinol diphenylphosphate, 2 parts of MAH-g-SEBS, 3.3 parts of SAN-g-GMA, 4 parts of dispersant, 13 parts of glass fiber, 0.8 part of antioxidant, 0.8 part of light stabilizer, 3.1 parts of processing aid, 8 parts of flame retardant.

[0040] Further, it is characterized in that the high heat-resistant ABS particles are modified by a heat-resistant modifier, and the heat-resistant modifier is N-isopropylmaleimide, N-cyclohexylmaleimide One or more of imide, N-phenylmaleimide, styrene-N-phenylmaleimide-maleic anhydride copolymer, SMA and diphenylmethane bismaleimide mixture of species.

[0041] Further, the antioxidant is composed of tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester a...

Embodiment 3

[0050] A high-strength heat-resistant and flame-retardant ABS alloy material comprises the following component raw materials in parts by weight:

[0051] 100 parts of high heat-resistant ABS particles, 23 parts of polyphenylene ether, 17 parts of PET, 9 parts of resorcinol diphenylphosphate, 1.7 parts of MAH-g-SEBS, 2.5 parts of SAN-g-GMA, 3 parts of dispersant 10 parts of glass fiber, 1 part of antioxidant, 1 part of light stabilizer, 4.7 parts of processing aid, and 9 parts of flame retardant.

[0052] Further, it is characterized in that the high heat-resistant ABS particles are modified by a heat-resistant modifier, and the heat-resistant modifier is N-isopropylmaleimide, N-cyclohexylmaleimide One or more of imide, N-phenylmaleimide, styrene-N-phenylmaleimide-maleic anhydride copolymer, SMA and diphenylmethane bismaleimide mixture of species.

[0053] Further, the antioxidant is composed of tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com