Efficient silicon carbide wafer machining method

A processing method and silicon carbide technology, applied in metal processing equipment, manufacturing tools, grinding tools, etc., can solve the problems of long processing cycle, large variation in the total thickness of wafer warpage, complex process procedures, etc., achieving a high degree of automation, The effect of shortening the machining time and simplifying the machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

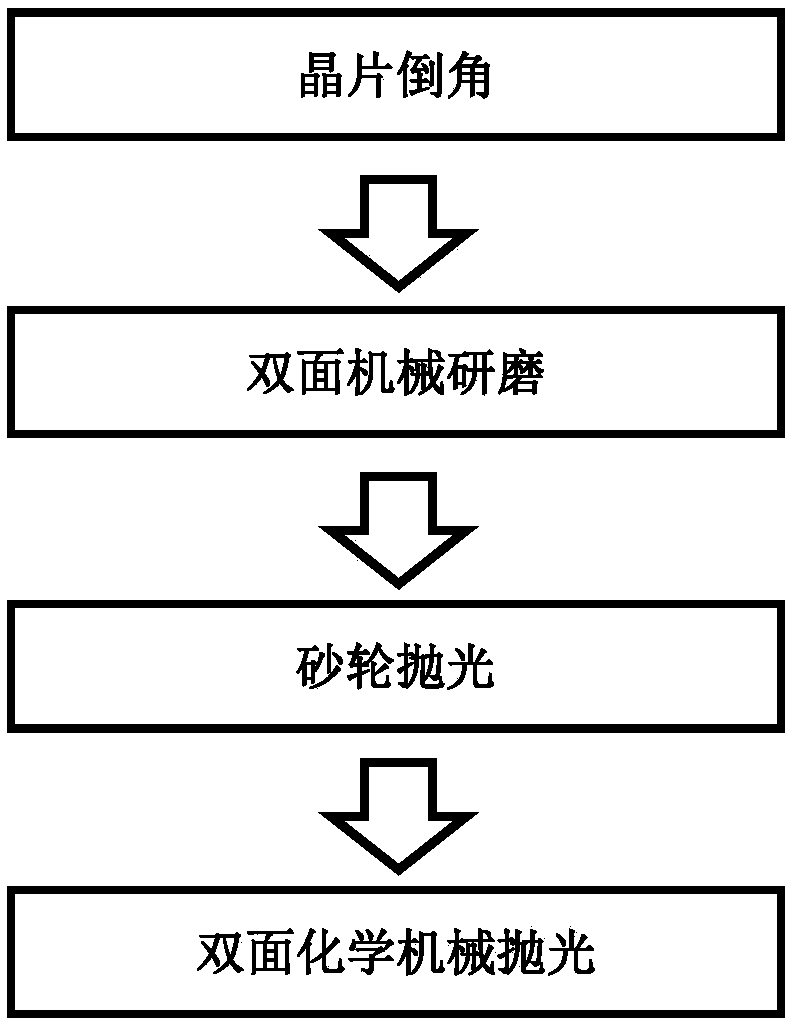

[0026] A kind of efficient processing method of silicon carbide wafer, its specific steps are as follows:

[0027] (1) Wafer chamfering;

[0028] (2) The chamfered wafer is ground on both sides, using a water-based diamond polishing fluid, the diamond particle size is 5 μm, the grinding pressure is 115 g / cm2, the grinding disc is a cast iron disc, and the surface of the cast iron disc is grooved. The interval is 10mm, the groove width is 1mm, the groove depth is 10mm, and the grinding time is 3.5h;

[0029] (3) Use automatic grinding wheel polishing equipment to grind and polish both sides of the wafer. First use a 5μm diamond grinding wheel with a rotation speed of 1500rpm, a grinding speed of 3μm / min, and a polishing time of 3 minutes; then use a 2μm diamond grinding wheel with a rotation speed of 2500rpm. The grinding speed is 1.5 μm / min, and the polishing time is 6 minutes; then a 1 μm diamond grinding wheel is used, the rotation speed is 3000 rpm, the grinding speed is 0...

Embodiment 2

[0035] A kind of efficient processing method of silicon carbide wafer, its specific steps are as follows:

[0036] (1) Wafer chamfering;

[0037] (2) The chamfered wafer is double-sidedly ground, using a water-based diamond polishing fluid, the diamond particle size is 3 μm, the grinding pressure is 160 g / cm2, the grinding disc is a cast iron disc, and the surface of the cast iron disc is grooved. The interval is 10mm, the groove width is 1mm, the groove depth is 10mm, and the grinding time is 3h;

[0038] (3) Use automatic grinding wheel polishing equipment to polish both sides of the wafer. First use a 10 μm diamond grinding wheel at a speed of 1000 rpm, a grinding speed of 5 μm / min, and a polishing time of 2 minutes; then use a 3 μm diamond grinding wheel at a speed of 2000 rpm. The grinding speed is 2 μm / min, and the polishing time is 8 minutes; then a 1 μm diamond grinding wheel is used, the rotation speed is 3000 rpm, the grinding speed is 0.3 μm / min, and the polishing ...

Embodiment 3

[0044] A kind of efficient processing method of silicon carbide wafer, its specific steps are as follows:

[0045] (1) Wafer chamfering;

[0046](2) The chamfered wafer is double-sidedly ground, using a water-based diamond polishing fluid, the diamond particle size is 5 μm, the grinding pressure is 160 g / cm2, the grinding disc is a cast iron disc, and the surface of the cast iron disc is grooved. The interval is 20mm, the groove width is 1mm, the groove depth is 10mm, and the grinding time is 3h;

[0047] (3) Use automatic grinding wheel polishing equipment to grind and polish both sides of the wafer. First use a 10μm diamond grinding wheel with a rotation speed of 800rpm, a grinding speed of 5μm / min, and a polishing time of 2 minutes; then use a 5μm diamond grinding wheel with a rotation speed of 1600rpm. The grinding speed is 2 μm / min, and the polishing time is 8 minutes; then a 2 μm diamond grinding wheel is used, the rotation speed is 3000 rpm, the grinding speed is 0.8 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com