A kind of sulfur-modified thermosetting polymer proton exchange membrane and preparation method thereof

A thermosetting and proton technology, which is applied in the field of thermosetting polymer proton exchange membrane and its preparation, can solve the problems of poor control of sulfonation degree, poor membrane performance, and high requirements for membrane forming conditions, and achieves reduction of methanol permeability and improvement of methanol permeability. Dimensional stability, effect of high proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

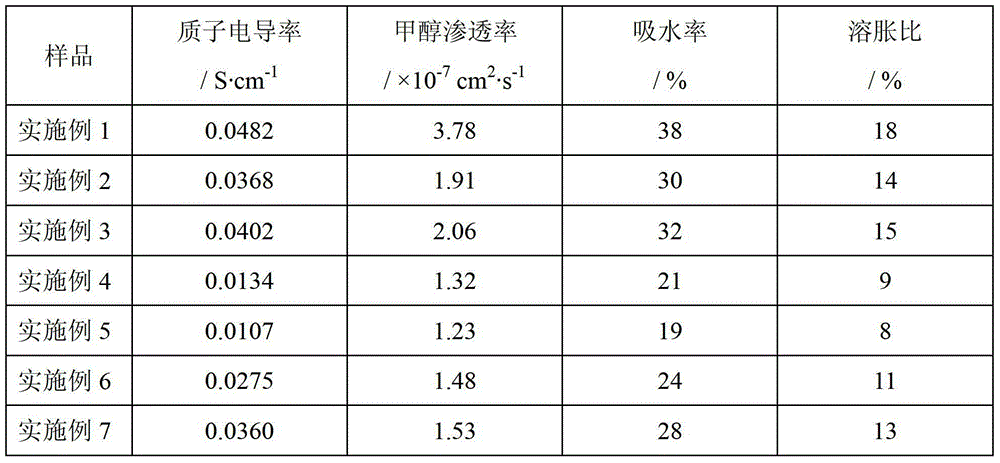

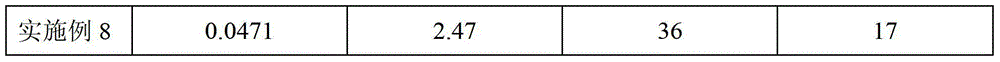

Embodiment 1

[0030] 100g natural rubber, 100g 2-acrylamido-2-methylpropanesulfonate sodium, 10g zinc oxide, 5g diphenylguanidine and 60g sulfur were mixed uniformly by an open mill to make a rubber compound; In a flat vulcanizer at 180°C, hot-pressed at 15MPa for 3h, the thickness of the obtained film is 300μm; the obtained film is soaked in sulfuric acid aqueous solution with a temperature of 90°C and a concentration of 0.5mol / L for 18 hours, and then Wash with deionized water until the pH value is 6-7, and finally vacuum-dry at 80° C. for 12 hours to obtain a sulfur-modified thermosetting polymer proton exchange membrane.

Embodiment 2

[0032] 100g butadiene rubber, 80g sodium styrene base sulfonate, 8g magnesium oxide, 2g2,2'-dithiodibenzothiazole, 2g2-mercaptobenzothiazole and 50g sulfur were mixed uniformly through an open mill to prepare into a mixed rubber; the obtained mixed rubber was hot-pressed at 15 MPa in a flat vulcanizer at 170 ° C for 2.5 hours, and the thickness of the obtained film was 100 μm; the obtained film was used at a temperature of 80 ° C and a concentration of 0.8 Soak in L sulfuric acid aqueous solution for 24 hours, then wash with deionized water until the pH value is 6-7, and finally vacuum-dry at 70° C. for 18 hours to obtain a sulfur-modified thermosetting polymer proton exchange membrane.

Embodiment 3

[0034] Mix 100g styrene-butadiene rubber, 60g sodium allyl sulfonate, 6g zinc stearate, 3g2,2'-dithiodibenzothiazole and 40g sulfur through an open mill to make a rubber compound; The mixed rubber was hot-pressed at 160°C in a flat vulcanizer at 15 MPa for 3 hours, and the thickness of the obtained film was 200 μm; the obtained film was soaked in an aqueous solution of sulfuric acid at a temperature of 70°C and a concentration of 1mol / L for 30 hours. , and then washed with deionized water until the pH value was 6-7, and finally vacuum-dried at 60° C. for 24 hours to obtain a sulfur-modified thermosetting polymer proton exchange membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com