Production method for high cold-pressing formability water atomized pre-alloyed powder

A production method and technology of pre-alloyed powder, applied in the field of powder metallurgy, can solve the problems of large specific surface area, good ductility, complex structure, etc., and achieve the effects of improving cold-press formability, wide applicability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

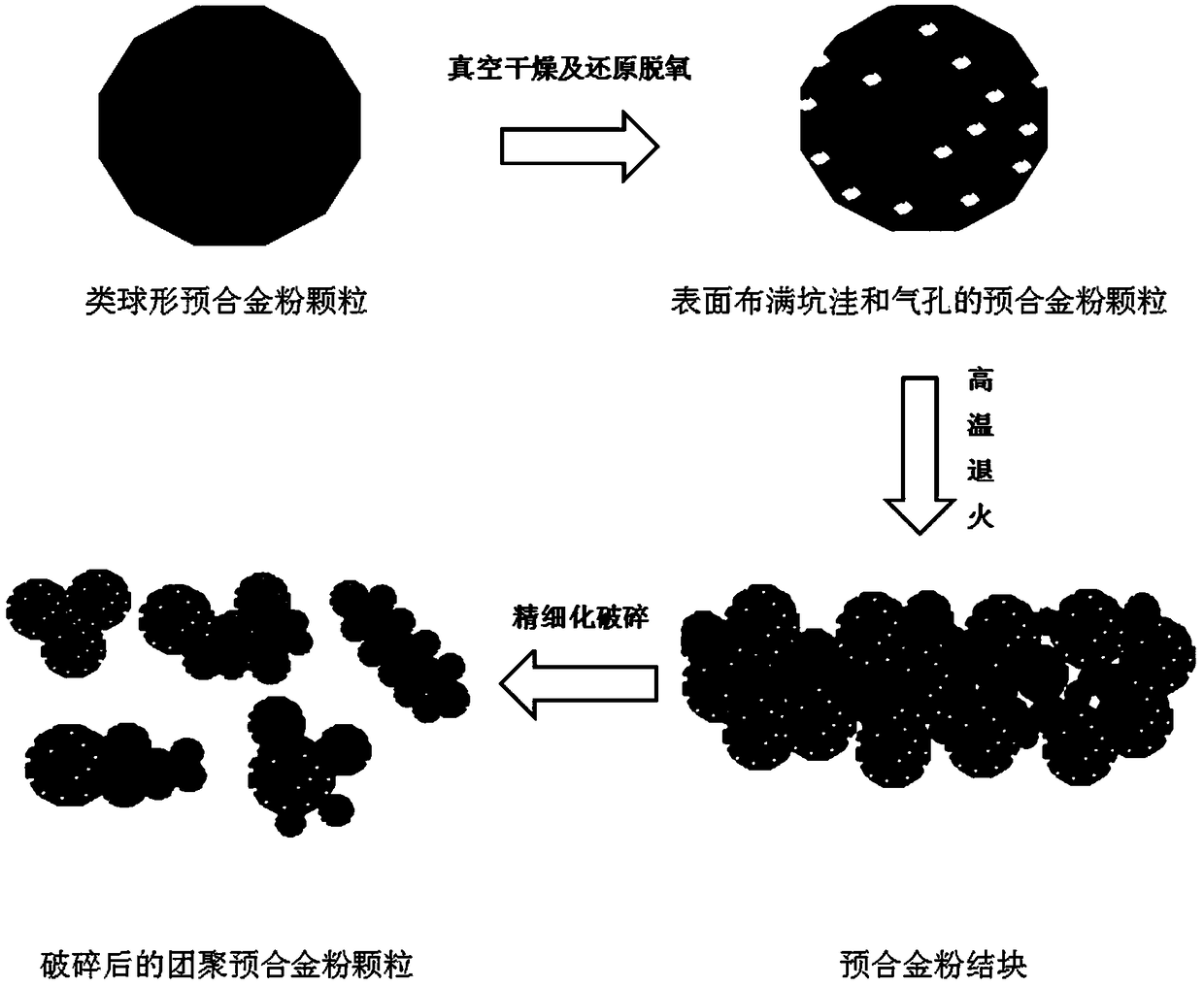

[0027] A production method of water atomized pre-alloyed powder with high cold press formability, the process flow chart is shown in figure 1 shown, including the following steps:

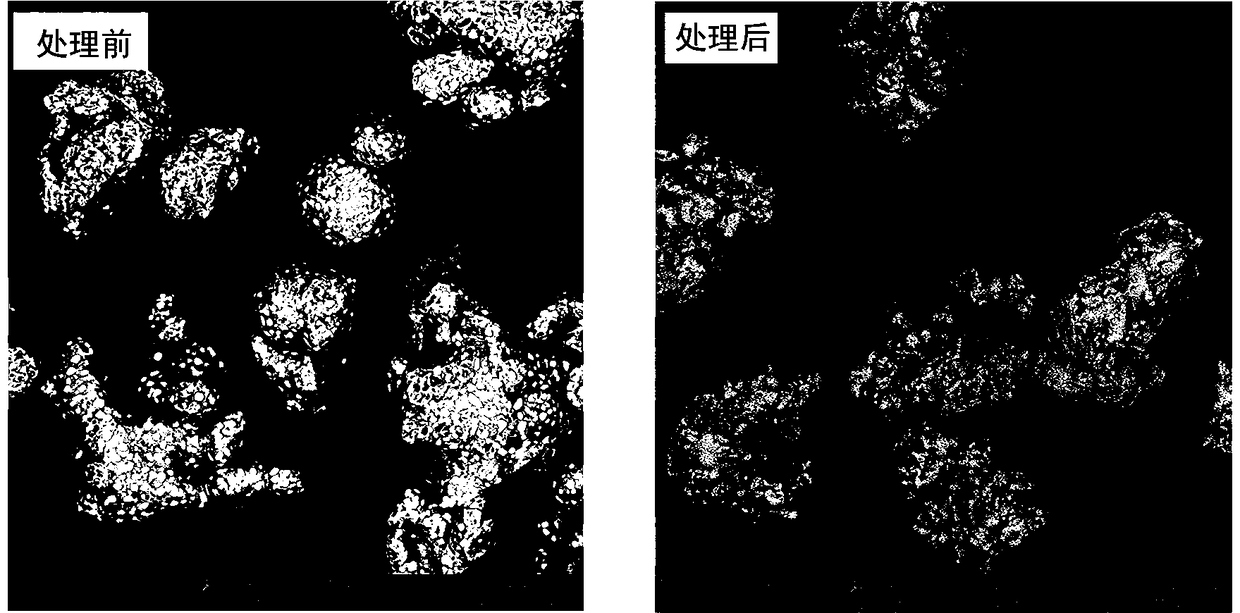

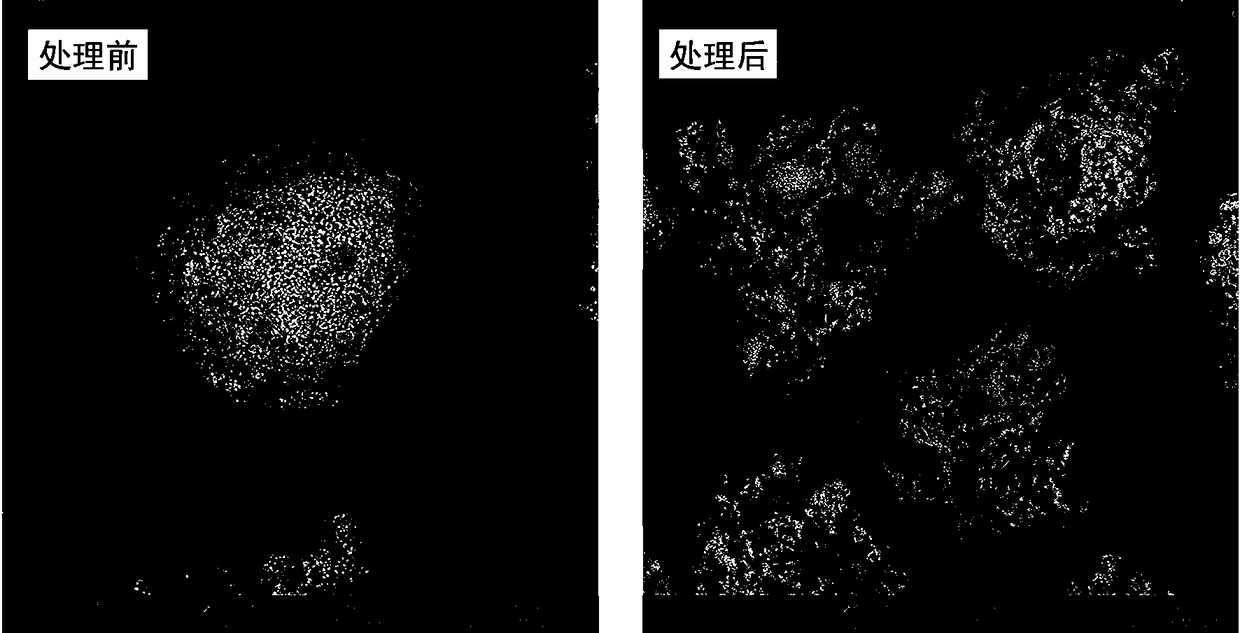

[0028] 1) Weigh 50kg of raw materials required for the production of pre-alloyed powder, including 70wt% iron and 30wt% copper; prepare semi-finished pre-alloyed powder by water atomization pulverization process, the temperature of the metal solution is 1550-1600°C, the nozzle diameter is 5mm, and the water flow angle 40°, water pressure 80Mpa, water flow rate 200L / min, use high-pressure water to break the molten steel into tiny droplets in the atomizer, and screen -400 mesh semi-finished iron-copper pre-alloyed powder after cooling. In other embodiments, the metal solution is any one or a combination of two or more of iron, copper, nickel, tin, zinc, cobalt, tungsten, molybdenum, vanadium, chromium, preferably, the pre-alloyed powder contains iron copper , one of iron copper nickel, iron copper n...

Embodiment 2

[0033] A production method of water atomized pre-alloyed powder with high cold press formability, the process flow chart is shown in figure 1 shown, including the following steps:

[0034] 1) Weigh 50 kg of raw materials required for the production of iron-based pre-alloyed powder for powder metallurgy, including 82 wt % iron, 13 wt % chromium, 1 wt % molybdenum, 1 wt % tungsten, 1 wt % vanadium, and 2 wt % carbon, using water The semi-finished pre-alloy powder is prepared by the atomization pulverization process. The temperature of the metal solution is 1650-1700°C, the diameter of the nozzle is 4.5mm, the water flow angle is 40°, the water pressure is 65Mpa, and the water flow rate is 180L / min. Broken into tiny droplets, screened -400 mesh semi-finished iron-based pre-alloyed powder after cooling;

[0035]2) Control the moisture content of the semi-finished pre-alloyed powder to 1 wt %, and the oxygen content to 0.6 wt %, and then put it in a vacuum drying oven at 100 ° C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com