A kind of biodegradable Zn-Na series zinc alloy and preparation method thereof

A biodegradable, zinc alloy technology, used in surgery, medical science and other directions, can solve the problem that zinc alloy is not suitable for medical implant materials, and achieve the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Composition, Preparation and Properties Testing of Biodegradable Zn-Na Binary Zinc Alloy.

[0063] The chemical composition of the four inventive examples of the zinc alloy is shown in Table 1-1, the added Na is 0.01-0.72%, and the balance is Zn. NaZn in the zinc alloy 13 The volume fraction of the second phase is 0.4-30%.

[0064] The preparation and processing flow of the zinc alloy is: continuous casting→hot extrusion→rolling. The raw materials for the continuous casting are metal Zn and Na according to the ratio of Table 1-1, they are put into the graphite crucible of the continuous casting equipment, after vacuuming, the high-purity argon gas is introduced into the protection, and then the graphite crucible is heated by induction. Raise the temperature to 620°C and keep the temperature for 10 minutes until the raw materials are melted and fully mixed under electromagnetic stirring. Heat the temperature of the graphite casting mold to 450°C, start the casting dev...

Embodiment 2

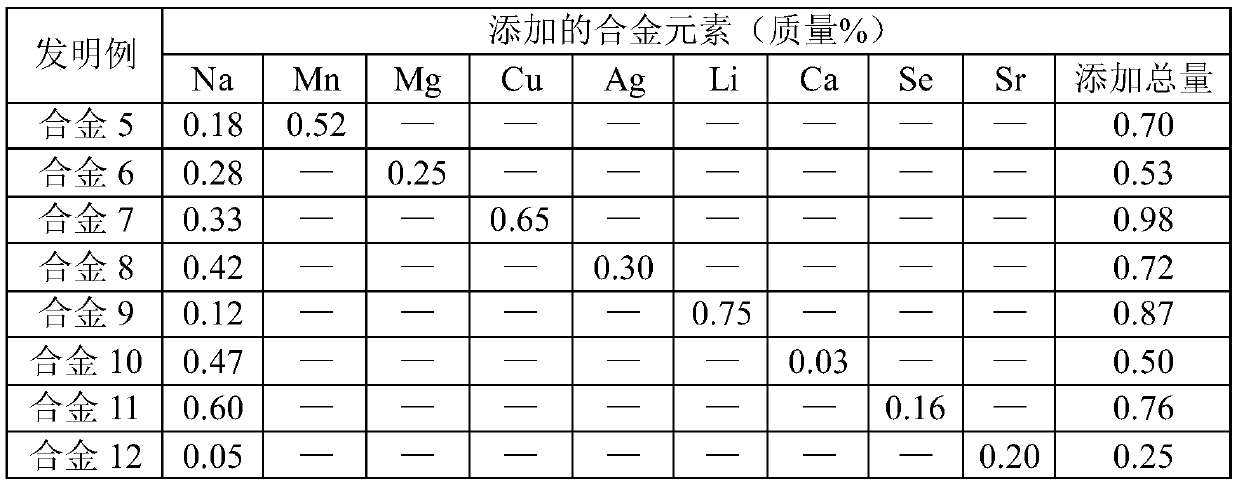

[0075] Composition, preparation and performance testing of biodegradable Zn-Na ternary zinc alloy.

[0076] The chemical composition of the 8 inventive examples of the zinc alloy is shown in Table 2-1. The total amount of alloying elements added is 0.25-0.98%, and the balance is Zn, which belongs to low-alloyed zinc alloy with low cost.

[0077] The preparation and processing flow of the zinc alloy is: continuous casting→hot extrusion→rolling. Use high-purity raw materials for batching according to the content of elements in Table 2-1, put them into the graphite crucible of the continuous casting equipment, put high-purity argon into the protection after vacuuming, and then raise the temperature of the graphite crucible to 650°C by induction heating , keep warm for 8 minutes until the raw materials are melted and fully mixed under electromagnetic force stirring. Heat the temperature of the graphite casting mold to 430°C, start the casting device to slowly pull the continuous ...

Embodiment 3

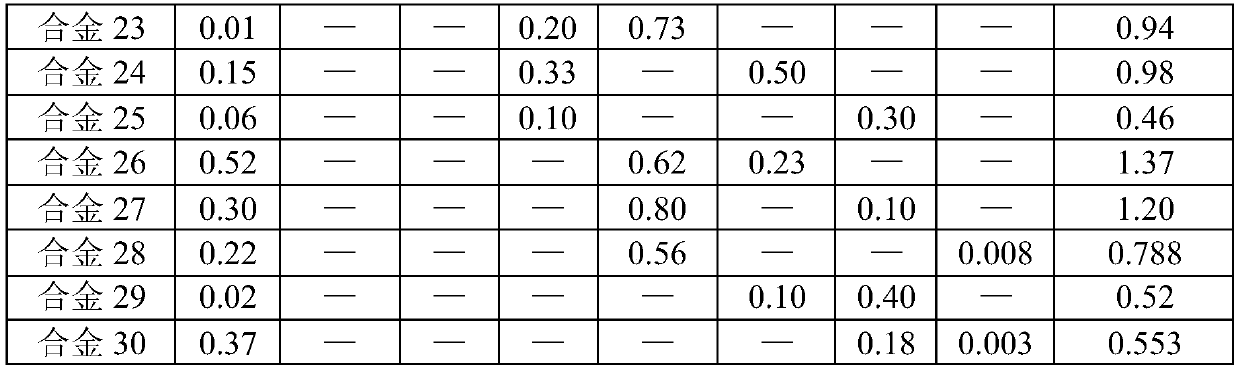

[0087] Composition, preparation and property test of biodegradable Zn-Na series quaternary zinc alloy.

[0088] The zinc alloy contains 4 alloying elements, 2 of which are essential alloying elements: Zn and Na, and the 3rd to 4th are further added alloying elements. The chemical composition of the 18 examples of the zinc alloy is shown in Table 3-1. The total amount of alloy elements added is 0.46-1.40%, and the balance is Zn, which belongs to low-alloyed zinc alloy and has low cost.

[0089] The preparation and processing flow of the zinc alloy is: continuous casting→homogenizing heat treatment→hot extrusion→rolling. Use high-purity raw materials for batching according to the content of elements in Table 3-1, put them into the graphite crucible of the continuous casting equipment, put high-purity argon into the protection after vacuuming, and then raise the temperature of the graphite crucible to 700°C by induction heating , keep warm for 5 minutes until the raw materials a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com