Pyrazinamide tablet and preparation method thereof

A technology of pyrazinamide tablets and pyrazinamide, which is applied in pill delivery, respiratory diseases, antibacterial drugs, etc., can solve the problems of difficult operation, small size of pyrazinamide tablets, high temperature, etc., and achieve fluidity and compression molding Good performance, improve production efficiency and save production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

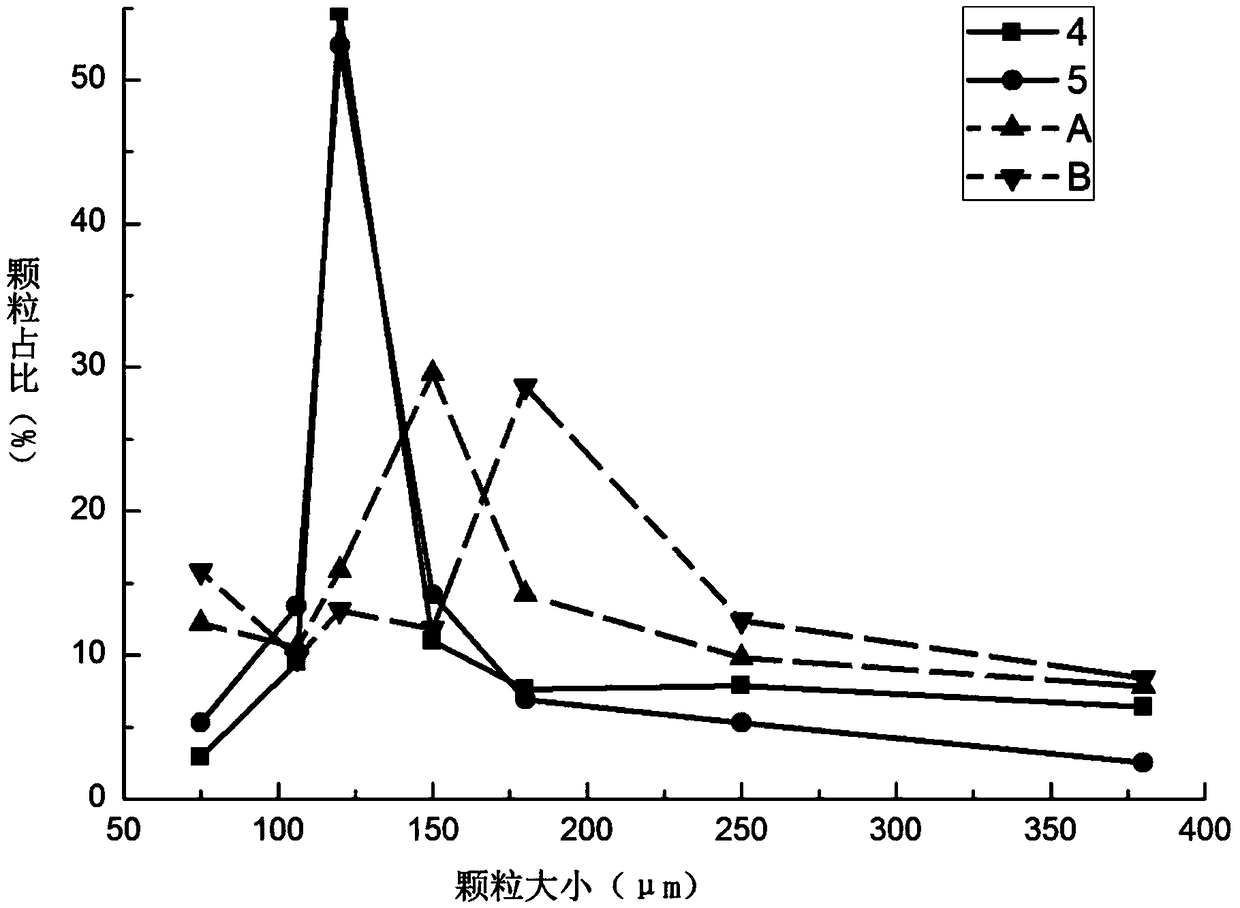

Image

Examples

Embodiment 1

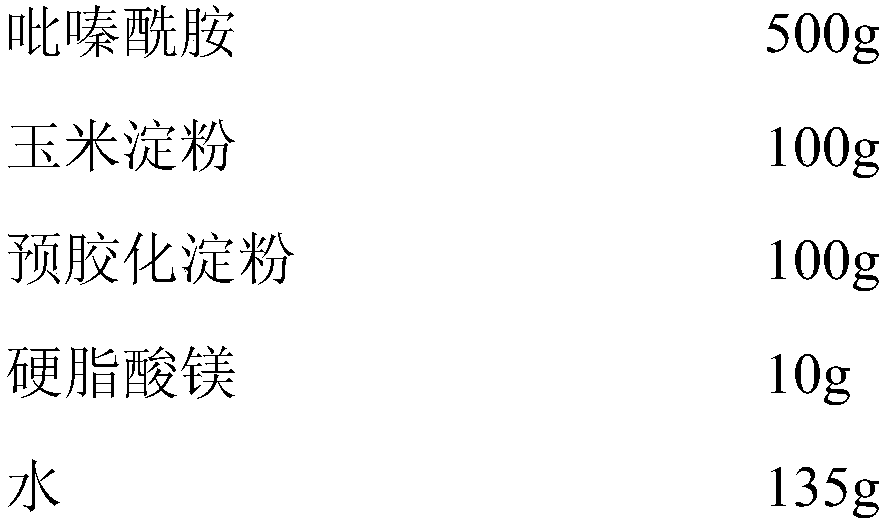

[0038] 1. Preparation prescription (made into 1000 tablets)

[0039]

[0040] 2. Preparation process

[0041] 1) mixing the raw material pyrazinamide, cornstarch and pregelatinized starch first, and set aside;

[0042] 2) Pulverize the mixed material through a pulverizer equipped with an 80-mesh screen, and place the material in a fluidized bed for granulation;

[0043] 3) The parameters of fluidized bed granulation are: material temperature during granulation and drying: 35-70°C; air inlet temperature during granulation and drying: 40-100°C; air volume during granulation and drying: 8 ~50m 3 / h; the solvent added during granulation is water, and the liquid addition speed is 10g / min;

[0044] 4) use 24 mesh sieves to carry out granulation to the prepared granules;

[0045] 5) Add lubricant magnesium stearate to the sized granules, mix for 10 minutes, and then compress into tablets to prepare a pyrazinamide tablet composition.

Embodiment 2

[0047] 1. Preparation prescription (made into 1000 tablets)

[0048]

[0049] 2. Preparation process

[0050] 1) mixing the raw material pyrazinamide, cornstarch and pregelatinized starch first, and set aside;

[0051] 2) Pulverize the mixed material through a pulverizer equipped with an 80-mesh screen, and place the material in a fluidized bed for granulation;

[0052] 3) The parameters of fluidized bed granulation are: material temperature during granulation and drying: 35-70°C; air inlet temperature during granulation and drying: 40-100°C; air volume during granulation and drying: 8 ~45m 3 / h; the solvent added during granulation is water, and the liquid addition rate is 6.0g / min;

[0053] 4) use 24 mesh sieves to carry out granulation to the prepared granule;

[0054] 5) Add lubricant magnesium stearate to the sized granules, mix for 10 minutes, and then compress into tablets to prepare a pyrazinamide tablet composition.

Embodiment 3

[0056] 1. Preparation prescription (made into 1000 tablets)

[0057]

[0058] 2. Preparation process

[0059] 1) mixing the raw material pyrazinamide, cornstarch and pregelatinized starch first, and set aside;

[0060] 2) Pulverize the mixed material through a pulverizer equipped with an 80-mesh screen, and place the material in a fluidized bed for granulation;

[0061]3) The parameters of fluidized bed granulation are: material temperature during granulation and drying: 30-60°C; air inlet temperature during granulation and drying: 40-90°C; air volume during granulation and drying: 8 ~40m 3 / h; the solvent added during granulation is water, and the liquid addition speed is 4.0g / min;

[0062] 4) use 24 mesh sieves to carry out granulation to the prepared granule;

[0063] 5) Add lubricant magnesium stearate to the sized granules, mix for 10 minutes, and then compress into tablets to prepare a pyrazinamide tablet composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com