Iron-supported zinc aluminate nano powder and preparation method thereof

A nano-powder, zinc aluminate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of low bonding strength, achieve simple and reliable operation process, high controllability, powder particle size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

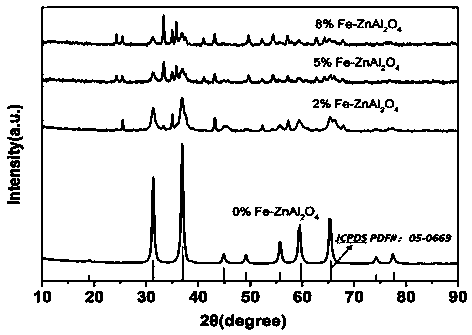

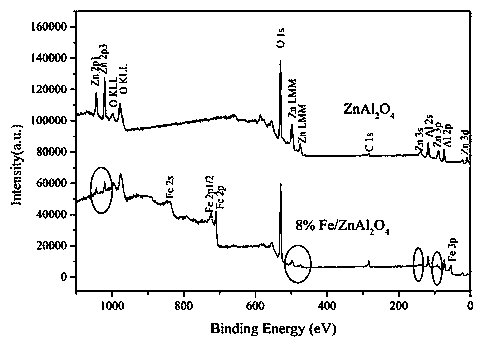

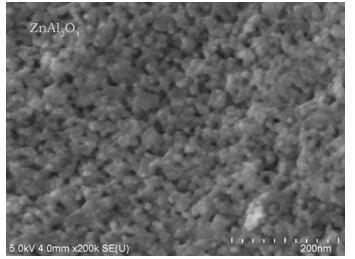

[0034] The iron-supported zinc aluminate nanopowder is prepared from zinc salt, aluminum salt, and iron salt as raw materials and adding surfactants. The particle size of the nanopowder is 20-200nm, and the surface of the nanopowder contains Fe. 2+ and Fe 3+ ion.

[0035] The preparation method of the iron-loaded zinc aluminate nanopowder, its specific steps include as follows:

[0036] Step 1, zinc salt (Zn(NO 3 ) 2 ·6H 2 O), aluminum salt (Al(NO 3 ) 3 9H 2 O) and surfactant (cetyltrimethylammonium bromide) were dissolved in deionized water to obtain a solution (the molar ratio of zinc salt, aluminum salt, surfactant and deionized water was 1:2:0.5:625 ), using concentrated ammonia water to adjust the pH value of the solution to 9, and magnetically stirred at room temperature for 4 hours; then at 180°C for 18 hours, a white precipitate was obtained, and the white precipitate after liquid-solid separation was repeatedly washed with ethanol and deionized water for 5 time...

Embodiment 2

[0040] The iron-supported zinc aluminate nanopowder is prepared from zinc salt, aluminum salt, and iron salt as raw materials and adding surfactants. The particle size of the nanopowder is 20-200nm, and the surface of the nanopowder contains Fe. 2+ and Fe 3+ ion.

[0041] The preparation method of the iron-loaded zinc aluminate nanopowder, its specific steps include as follows:

[0042] Step 1, zinc salt (Zn(NO 3 ) 2 ·6H 2 O), aluminum salt (Al(NO 3 ) 3 9H 2 O) and surfactant (cetyltrimethylammonium bromide) were dissolved in deionized water to obtain a solution (the molar ratio of zinc salt, aluminum salt, surfactant and deionized water was 1:2:0.5:625 ), using concentrated ammonia water to adjust the pH value of the solution to 9, and magnetically stirred at room temperature for 4 hours; then at 180°C for 18 hours, a white precipitate was obtained, and the white precipitate after liquid-solid separation was repeatedly washed with ethanol and deionized water for 5 time...

Embodiment 3

[0046] The iron-supported zinc aluminate nanopowder is prepared from zinc salt, aluminum salt, and iron salt as raw materials and adding surfactants. The particle size of the nanopowder is 20-200nm, and the surface of the nanopowder contains Fe. 2+ and Fe 3+ ion.

[0047] The preparation method of the iron-loaded zinc aluminate nanopowder, its specific steps include as follows:

[0048] Step 1, zinc salt (Zn(NO 3 ) 2 ·6H 2 O), aluminum salt (Al(NO 3 ) 3 9H 2 O) and surfactant (cetyltrimethylammonium bromide) were dissolved in deionized water to obtain a solution (the molar ratio of zinc salt, aluminum salt, surfactant and deionized water was 1:2:0.5:625 ), using concentrated ammonia water to adjust the pH value of the solution to 9, and magnetically stirred at room temperature for 4 hours; then at 180°C for 18 hours, a white precipitate was obtained, and the white precipitate after liquid-solid separation was repeatedly washed with ethanol and deionized water for 5 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com