Lithium sulfur-lithium ion hybrid battery, cathode material for lithium sulfur-lithium ion hybrid battery and preparation method thereof

A technology of battery positive electrode and positive electrode material, applied in battery electrodes, electrode manufacturing, electrode heat treatment, etc., can solve the problems of poor cycle performance, low capacity, low theoretical battery capacity, etc., and achieve good stability, good conductivity, and enhanced capacity. exert the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of component sulfur (S), multi-walled carbon nanotubes (MCNT), and spincrystalline lithium titanate (LTO) composite positive electrode materials, the specific preparation process is as follows:

[0052] 200mg MCNT ultrasonic 1h dispersed in 20mL absolute ethanol, 79.3mg LiOH·H 2 O was dissolved in 30mL deionized water, added to the above MCNT suspension, 580.24mg of titanium sulfate was added to the above solution, stirred evenly, transferred to an autoclave, heated to 160°C, and after solvothermal reaction for 3 hours, transferred to a beaker The solvent was evaporated to dryness at 60°C, washed with deionized water, and then vacuum-dried at 100°C for 12 hours to obtain a black powder. The black powder was calcined at 300° C. for 12 hours in an air atmosphere to obtain a composite lithium titanate cathode material (MCNT / LTO). Weigh 300mg of MCNT / LTO and 450mg of sublimed sulfur, grind for half an hour, seal it in a tube furnace, and heat-treat it under arg...

Embodiment 2

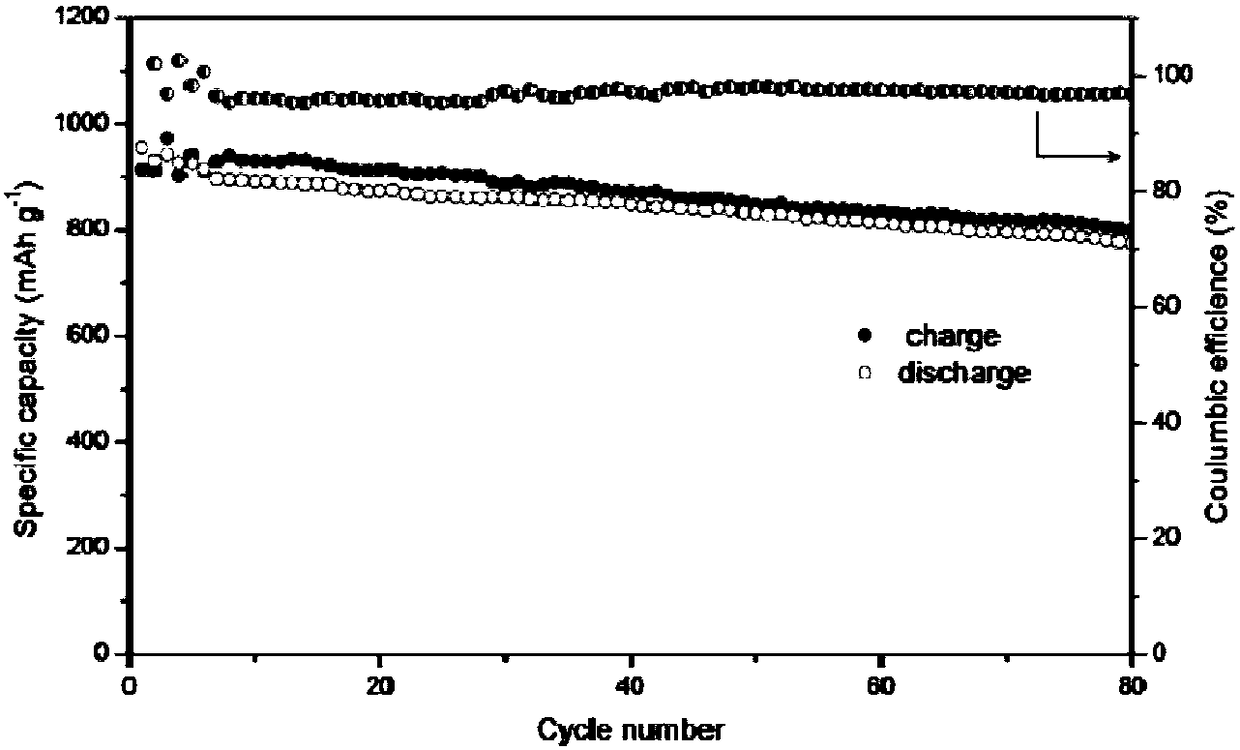

[0056] Prepare the lithium battery positive electrode sheet with the same material ratio and thickness as in Example 1. The positive electrode sheet of the prepared lithium battery is assembled into a liquid button lithium battery by using the positive electrode sheet / carbonate electrolyte / lithium sheet, the charge and discharge cut-off voltage is 1-3V, and different rate charge and discharge tests are carried out at room temperature. The specific capacity of the first cycle of 0.2C discharge is 935mAhg -1 , after 10 cycles, the specific discharge capacity at 0.5C is 754.5mAhg -1 , after 20 cycles, the specific discharge capacity at 1C is 651.2mAhg -1 , after 30 cycles, the specific discharge capacity at 2C is 485mAhg -1 , when the rate gradually returns to 0.2C, the discharge specific capacity is 867mAhg after 20 cycles -1 , with an average Coulombic efficiency of 97.9%.

Embodiment 3

[0058] Preparation of component sulfur (S), graphene, spin crystal lithium titanate (LTO) composite positive electrode material, the specific preparation process is as follows:

[0059] 200mg of graphene was dispersed in 200mL of absolute ethanol by ultrasound for 1h, and 79.3mg of LiOH·H 2 O was dissolved in 30mL deionized water, added to the above graphene suspension, heated to 80°C, 1000rmin -1 Stir quickly, dissolve 755.59mg of n-butyl titanate in 30mL of absolute ethanol, add dropwise to the above solution, after the dropwise addition, place in a closed container and continue stirring for 2h, transfer to a beaker and evaporate the solvent to dryness at 60°C Vacuum drying at 100°C for 12 hours gave black powder. The black powder was calcined at 700° C. for 3 hours under an argon atmosphere to obtain a composite lithium titanate cathode material. Weigh 300 mg of graphene / LTO and 450 mg of sublimed sulfur, grind for half an hour, seal in a tube furnace, and heat-treat for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com