Preparation method of metallic coating applied to corrosive environment

A metal coating and corrosive environment technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of wear resistance and corrosion resistance performance reduction, economic loss, hidden safety hazards, etc., to achieve excellent wear reduction, huge The effect of developing potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a metal coating applied in a corrosive environment, which is characterized in that it includes the following steps:

[0031] (1) Fully mix the iron-based amorphous powder and a polyvinyl alcohol solution with a mass fraction of 4-5% to obtain a preset powder;

[0032] (2) Pretreating the surface of the 316L stainless steel plate, after the pretreatment, the preset powder is evenly coated on the 316L stainless steel plate, and dried;

[0033] (3) Cladding the preset powder on the metal substrate with a laser, so that the metal substrate and the preset powder achieve metallurgical bonding;

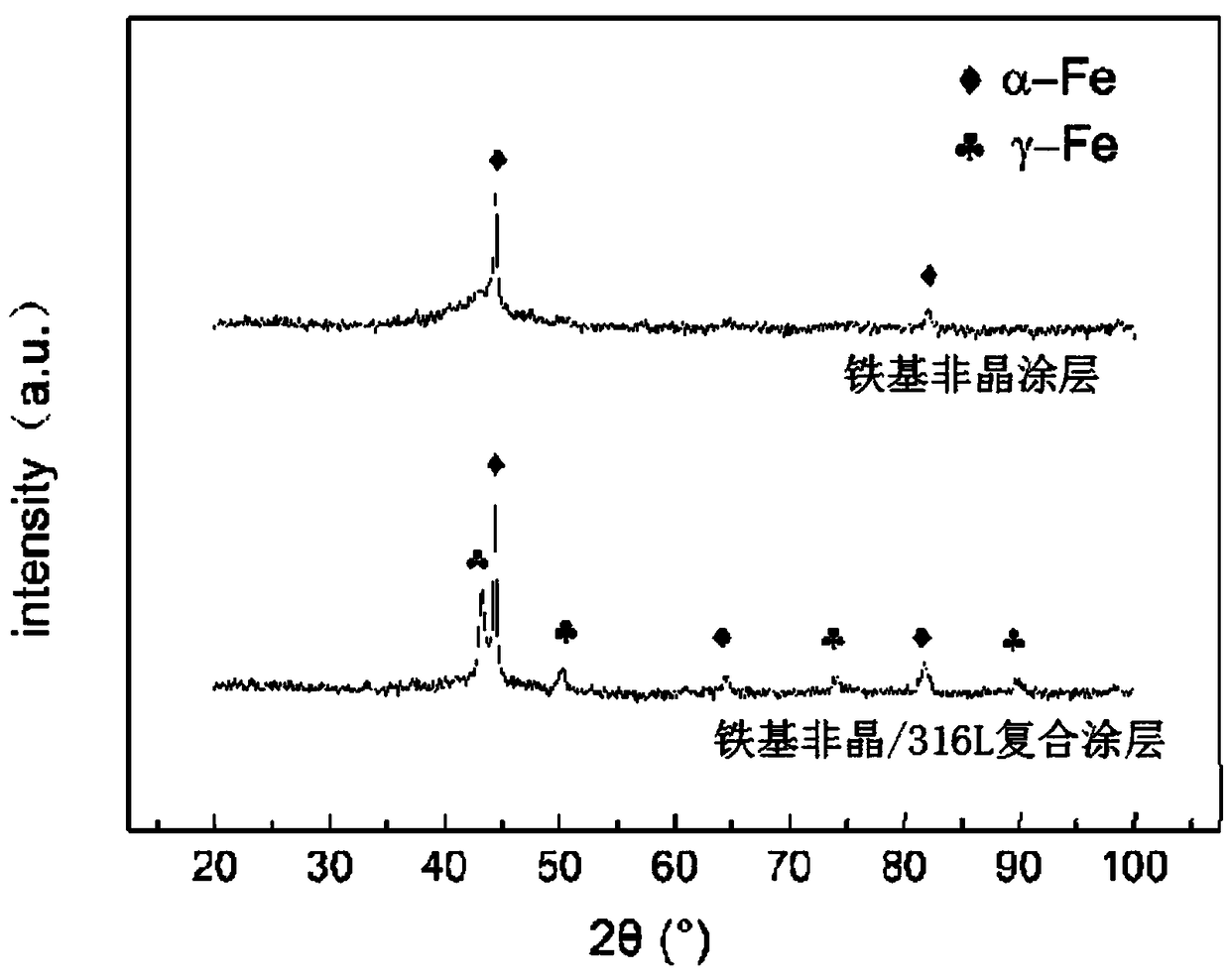

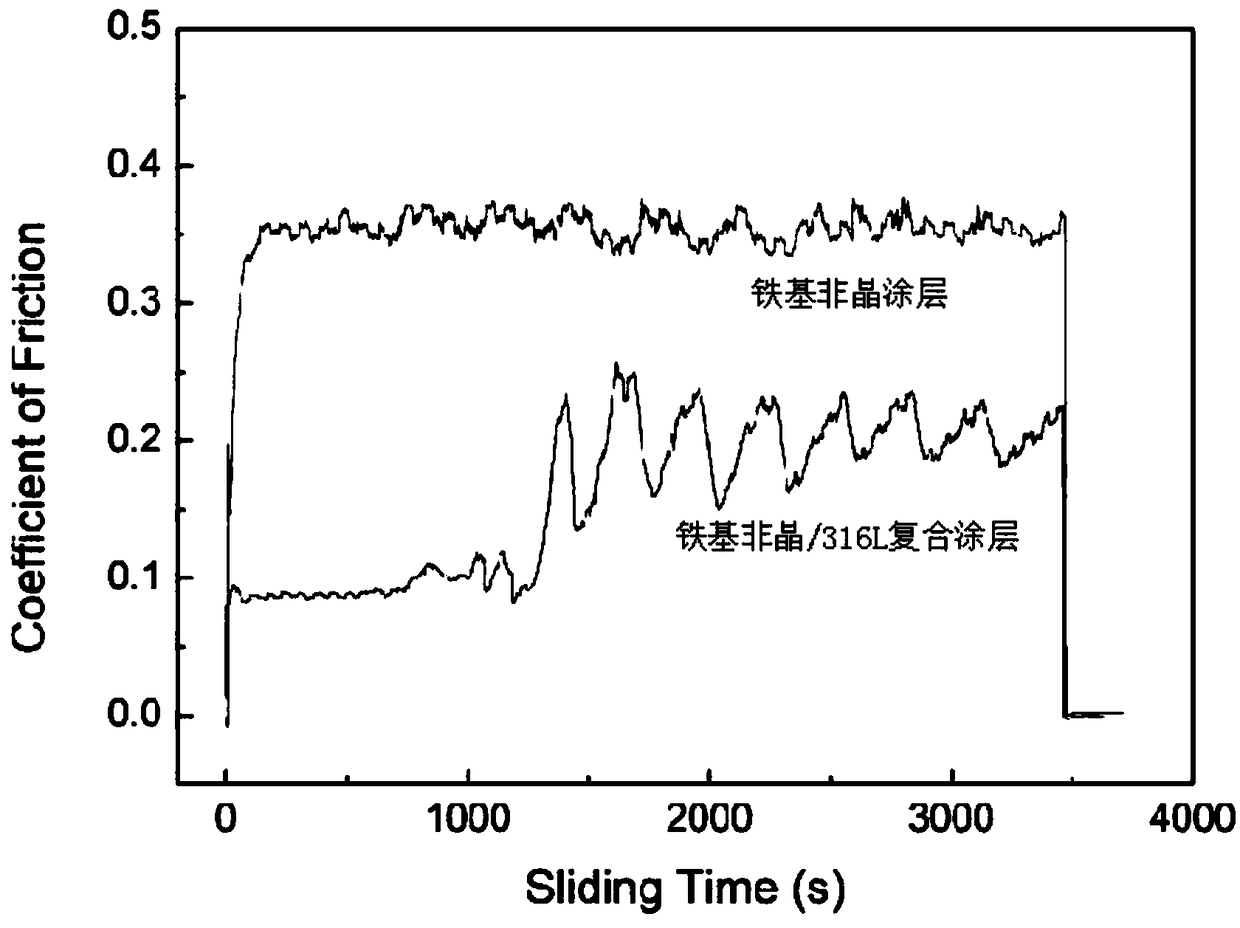

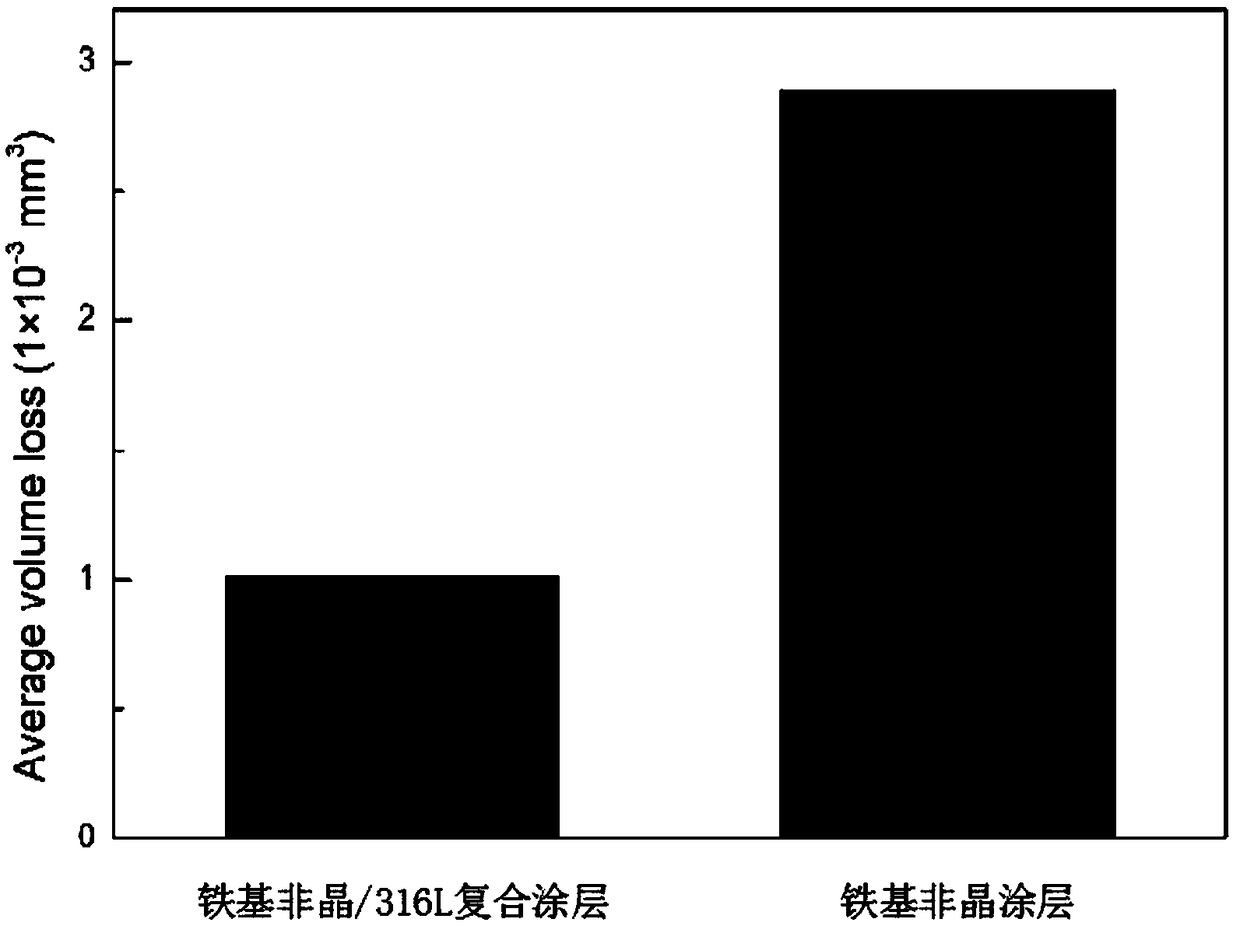

[0034] (4) Repeated coating of a layer of preset powder, cladding the second layer by laser to obtain an amorphous / metal composite coating, and carried out characterization.

[0035] Step (1), using commercially available iron-based amorphous powder (purity 99.9%, particle size 200-325 mesh) as the raw material, the atomic percentages o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com