Method for preparing ultra-coarse tungsten powder through high-temperature liquid phase reduction of tungsten oxide

A technology of tungsten oxide and tungsten powder, applied in the field of metal powder metallurgy, can solve the problems of low production efficiency, high equipment requirements, long reduction time, etc., achieve high production efficiency, short reduction time, improve nucleation and growth effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

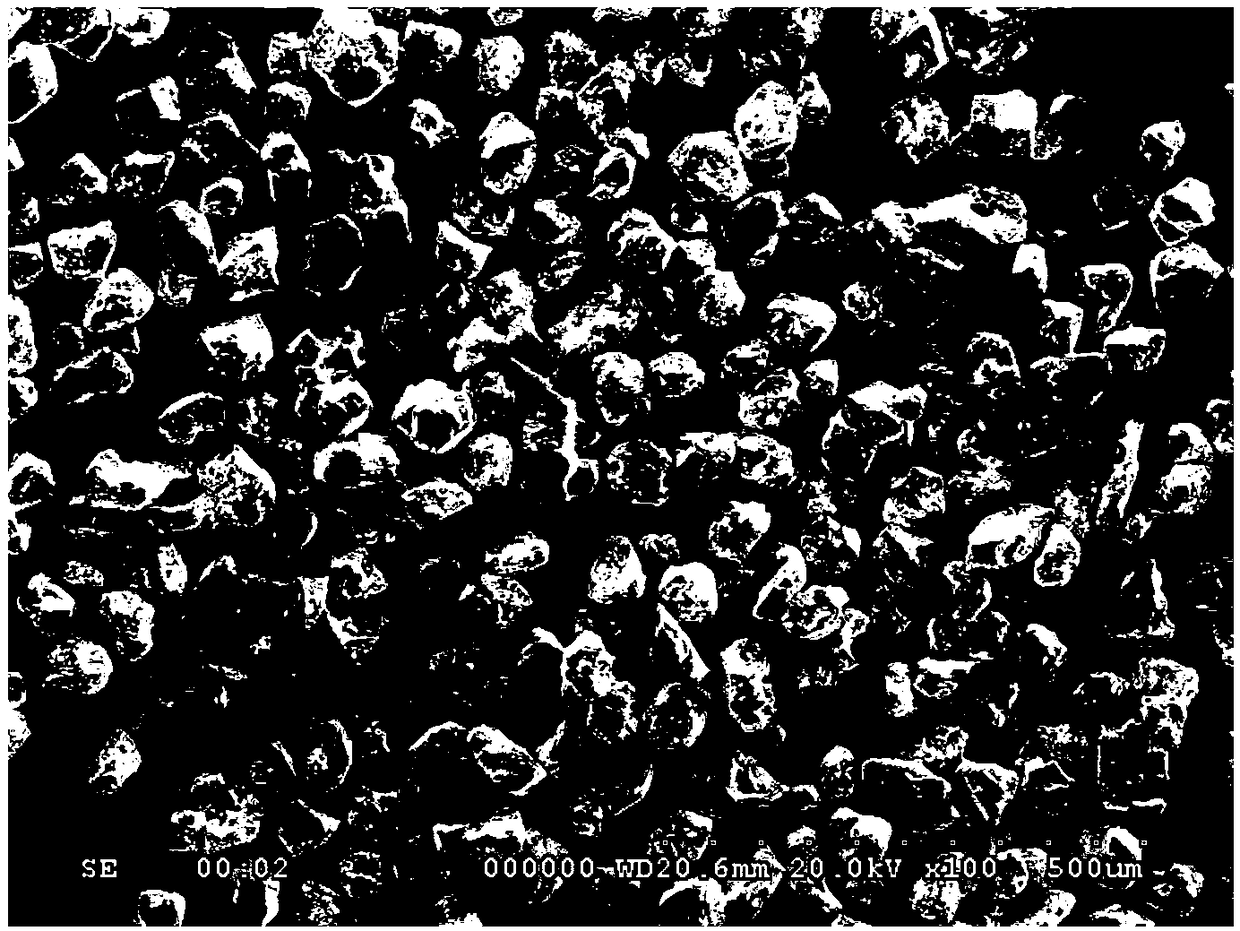

[0017] A. Take 20g of yellow tungsten trioxide powder, put it into the tube furnace, pass in argon as a protective gas, keep it for 0.5h after the temperature rises to 1500°C, turn off the argon, and pass pure hydrogen into the tube furnace for Reduction, continue to keep warm for 1.5h, and then cool with the furnace to prepare ultra-coarse tungsten powder.

[0018] The tungsten powder prepared by the method described above has uniform particle size, good dispersibility, and an average particle size of 58 μm. The SEM picture is shown in figure 1 shown.

Embodiment 2

[0020] A. Dosing according to the following mass percentage, 95% tungsten trioxide, 5% tungsten powder (particle size range 0.2 ~ 1.0 μm), take 19g tungsten trioxide powder and 1g tungsten powder and mix evenly;

[0021] B. Put the uniformly mixed powder into the tube furnace, feed in argon as a protective gas, keep it for 0.5h after the temperature rises to 1500°C, turn off the argon, feed pure hydrogen into the tube furnace for reduction, continue Keep it warm for 1.5h, then cool down with the furnace to prepare ultra-coarse tungsten powder.

[0022] The tungsten powder prepared by the method described above has uniform particle size, good dispersion, and an average particle size of 65 μm. See the SEM picture figure 2 shown.

Embodiment 3

[0024] A. Dosing according to the following mass percentages, 90% tungsten trioxide, 10% tungsten powder (particle size range 0.2-1.0 μm), take 18g yellow tungsten trioxide powder and 2g tungsten powder and mix evenly;

[0025] B. Put the uniformly mixed powder into the tube furnace, feed in argon as a protective gas, keep it for 0.5h after the temperature rises to 1500°C, turn off the argon, feed pure hydrogen into the tube furnace for reduction, continue Keep it warm for 1.5h, then cool down with the furnace to prepare ultra-coarse tungsten powder.

[0026] The tungsten powder prepared by the method described above has a uniform particle size, good dispersion, and an average particle size of 70 μm. The SEM picture is shown in image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com