A method for grow a protective layer on that surface of a metal negative electrode of a secondary lithium battery

A technology for secondary lithium batteries and metal negative electrodes, applied in the field of lithium ion batteries, can solve the problems of difficult operability, complicated preparation methods, poor cycle performance of lithium dendrite growth batteries, etc., to solve lithium dendrites, improve cycle performance, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This example is used to illustrate the preparation and application of the metal lithium negative electrode surface protection layer of the present invention.

[0020] In the glove box, respectively dissolve 2-methylimidazole and cobalt nitrate in dimethyl carbonate (DMC), then quickly pour the cobalt nitrate solution into the methylimidazole solution, and after 30 seconds, commercial lithium metal Put it into the above mixed solution, let it stand for an hour, take it out, rinse it with DMC, and let it dry naturally.

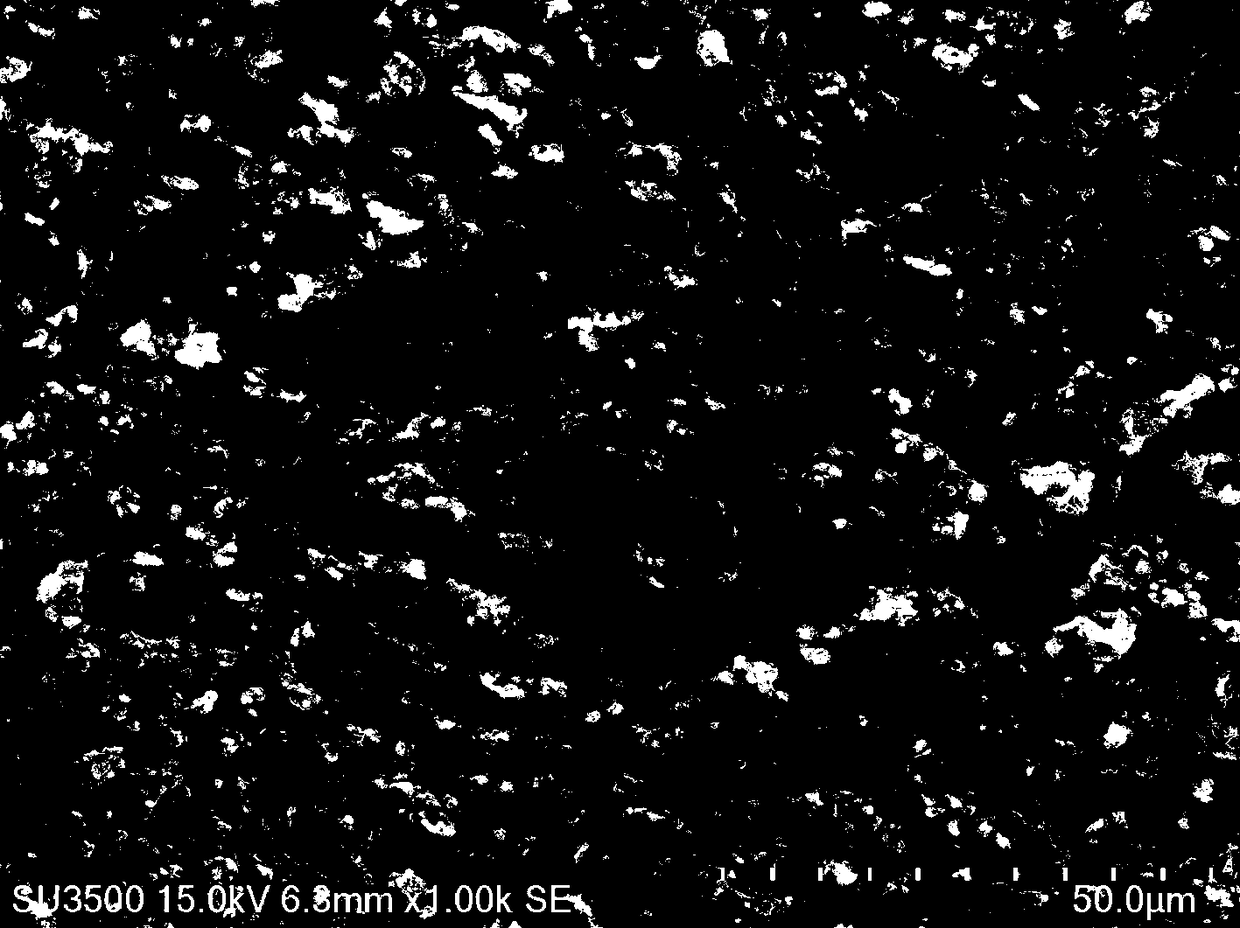

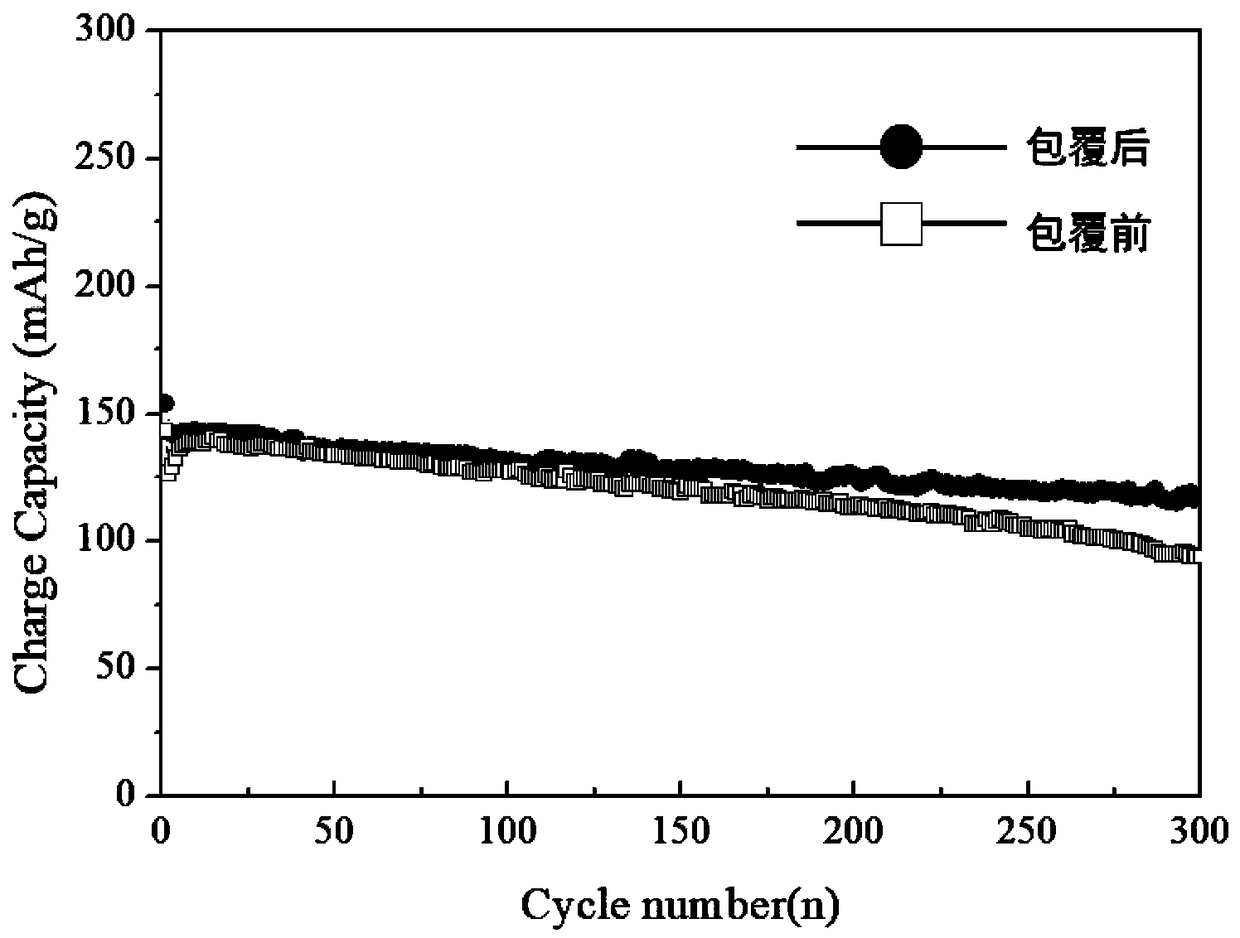

[0021] The scanning electron microscope (SU-3500, Hitachi, Japan) photo of the surface of metal lithium electrode is as follows figure 1 As shown, the visible surface is basically flat. The surface of the treated lithium sheet is as follows figure 2 As shown, it can be seen that there is obviously a covering layer on the surface of this bright lithium sheet. The lithium sheet before and after treatment was used as the negative electrode of the simulat...

Embodiment 2

[0027] This example is used to illustrate the preparation and application of the metal lithium negative electrode surface protection layer of the present invention.

[0028] In the glove box, dissolve N-ethylimidazole and ferric sulfate in dimethyl carbonate (DMC), and quickly pour the cobalt nitrate solution into the methylimidazole solution. After 30 seconds, put the lithium-boron alloy into the In the above mixed solution, after standing still for one hour, take it out, rinse it with DMC, dry it naturally, and record it as A2.

[0029] Then, the positive electrode of the simulated battery was prepared according to the method of Example 1. After 300 cycles, the specific capacity of the positive electrode of the simulated battery phase remained at 130 mAh / g, see Table 1.

Embodiment 3

[0031] This example is used to illustrate the preparation and application of the metal lithium negative electrode surface protection layer of the present invention.

[0032] In the glove box, 1-vinylimidazole and ferrous sulfate were dissolved in dimethyl carbonate (DMC), and then the cobalt nitrate solution was quickly poured into the methylimidazole solution. After 30 seconds, the lithium aluminum alloy was placed Put it into the above mixed solution, stand still for one hour, take it out, rinse it with DMC, dry it naturally, and record it as A3.

[0033] Then, the positive electrode of the simulated battery was prepared according to the method of Example 1. After 300 cycles, the specific capacity of the positive electrode of the simulated battery phase remained at 128 mAh / g, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com