Method for improving stability of anode material of lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of material performance deterioration, material capacity decay, poor cycle stability, etc., to improve cycle performance and improve energy density. , the effect of improving thermal stability and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

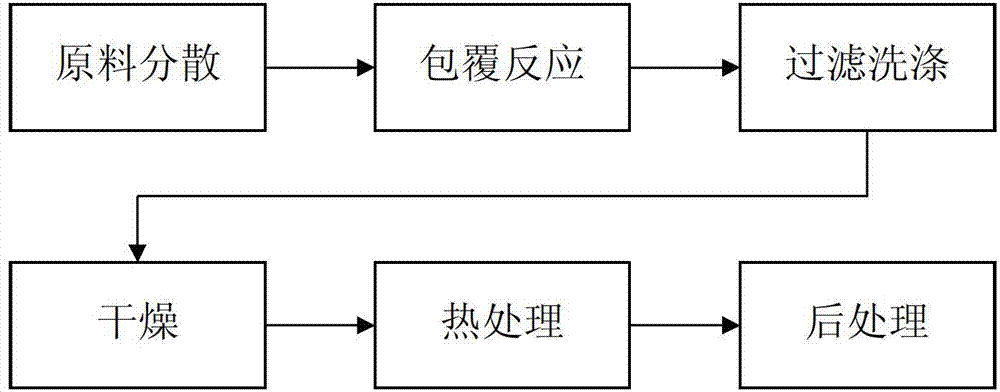

Image

Examples

Embodiment 1

[0029] at 100dm 3 Add 50dm to the reactor 3 Pure water, turn on the stirring device, add 15kg of lithium manganate material, fully stir and disperse. Prepare 0.1mol·dm -3 cerium nitrate solution and 0.1mol dm -3 diammonium hydrogen phosphate solution. Use a metering pump to separate the above two solutions at a distance of 50 cm 3 min -1 The rate is injected into the reactor at multiple points, and the injection is stopped after 170 minutes. After continuing to stir for 30 minutes, the mixture in the reaction kettle was introduced into a centrifugal filter, and the solid matter was fully washed in the centrifugal filter. The solid obtained after filtering and washing was placed in an oven at 105° C. for drying. The dried solid was incubated at 500°C for 8h. After cooling, the obtained solids are pulverized, classified and sieved to obtain the product.

[0030] The cycle stability of the product made in this example is significantly improved compared with the untreated...

Embodiment 2

[0032] at 8m 3 Add 3m to the reactor 3 Pure water, turn on the stirring device, add 7000kg of lithium cobalt oxide material, fully stir and disperse. Prepare 1.0mol·dm -3 cerium chloride solution and 1.0mol dm -3 sodium phosphate solution. Use a metering pump to separate the above two solutions at 2.0dm 3 min -1 The rate is injected into the reactor at multiple points, and the injection is stopped after 150 minutes. After continuing to stir for 30 minutes, the mixture in the reaction kettle was introduced into a filter press, and the solids were fully washed in the filter press. The solid obtained after filtering and washing was placed in an oven at 150° C. for drying. The dried solid was incubated at 800°C for 2h. After cooling, the obtained solids are pulverized, classified and sieved to obtain the product.

[0033] The cycle stability of the product prepared in this example is significantly improved compared with the untreated material. Under the charge cut-off vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com