Detection method for content of brominated flame retardants (BFRs) in food

A brominated flame retardant and detection method technology, applied in the detection field of brominated flame retardant content in food, can solve the problem of increasing the loss of target objects and the intensity of experiments, increasing the risk of decomposition of high-brominated substances, and large baseline interference and other problems, to achieve the effect of preventing degradation, high sensitivity, and overcoming cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

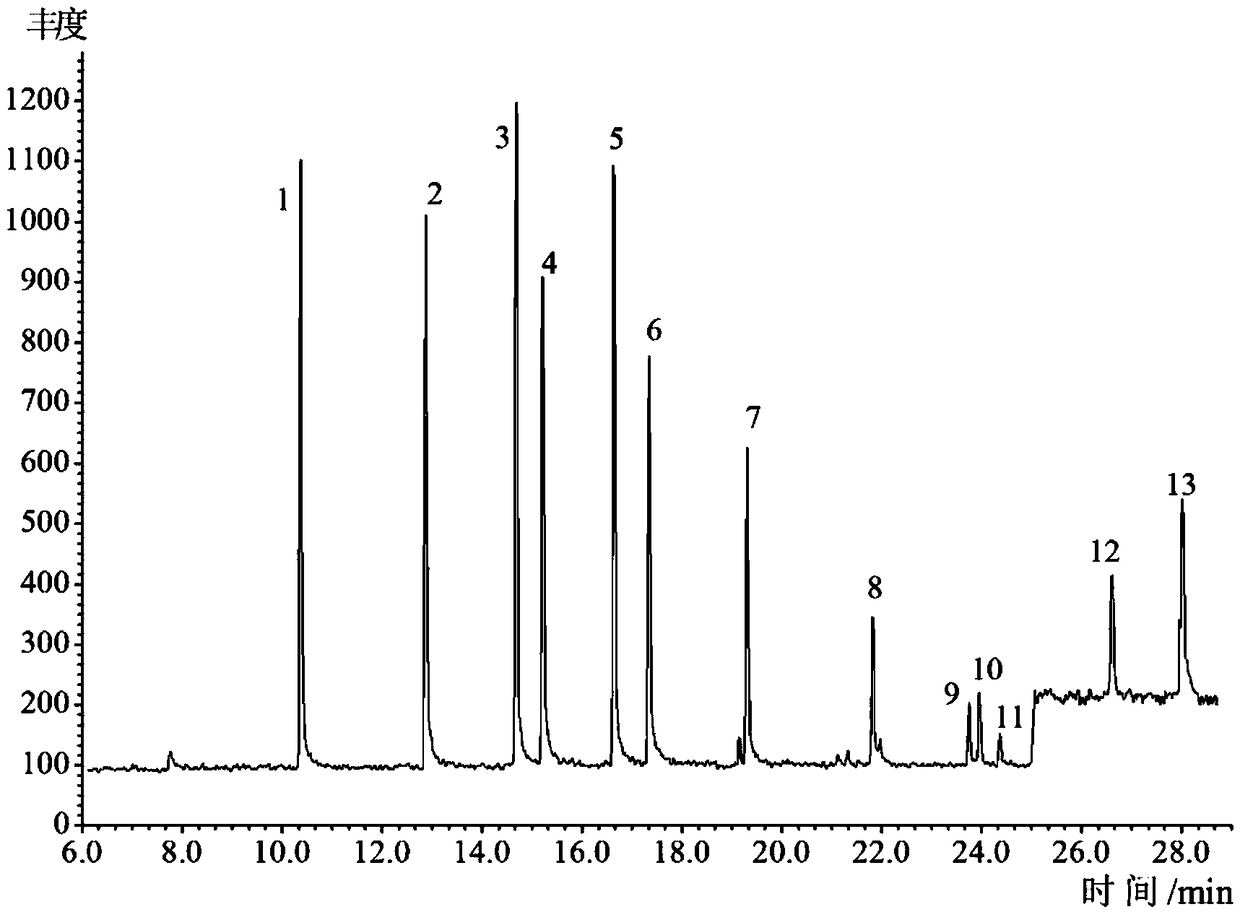

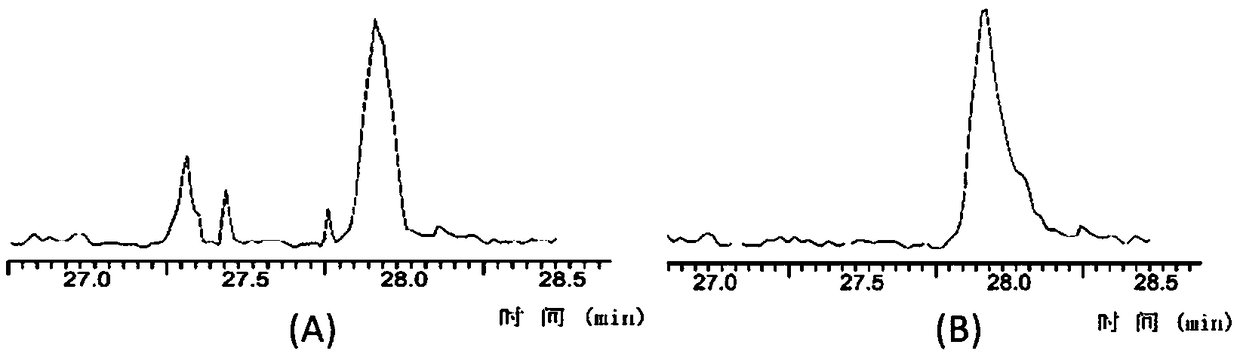

[0057] This embodiment focuses on GC-NCI-MS analysis of 13 kinds of brominated flame retardants to ensure the accuracy of qualitative and quantitative.

[0058] Step 1: Use BDE-CSM PBDE8 mixed standard, BDE-203, BDE-206, BDE-207, BDE-208 and DBDPE single standard purchased from Bailingwei Technology Co., Ltd., with a concentration of 1000mg / L. Alkanes are formulated into PBDEs (low brominated BDEs: BDE-28, BDE-47, BDE-99, BDE-100, BDE-153, BDE-154, BDE-183) with a standard working curve concentration of 0.5, 1.0, 5.0, 10.0 and 50.0μg / L, high bromine-BDE (BDE-203, BDE-206, BDE-207, BDE-208) standard working curve concentration is 1.0, 5.0, 10.0, 50.0 and 100.0μg / L, BDE209 and DBDPE standard The working curve concentration is the mixed standard working solution of 5.0, 10.0, 50.0, 100.0 and 500.0 μg / L.

[0059] Step 2: Set gas chromatography-mass spectrometry conditions: select DB-5HT capillary column (15m×0.25mm i.d., 0.10μm, Agilent); splitless injection, injection volume 1.0...

Embodiment 2

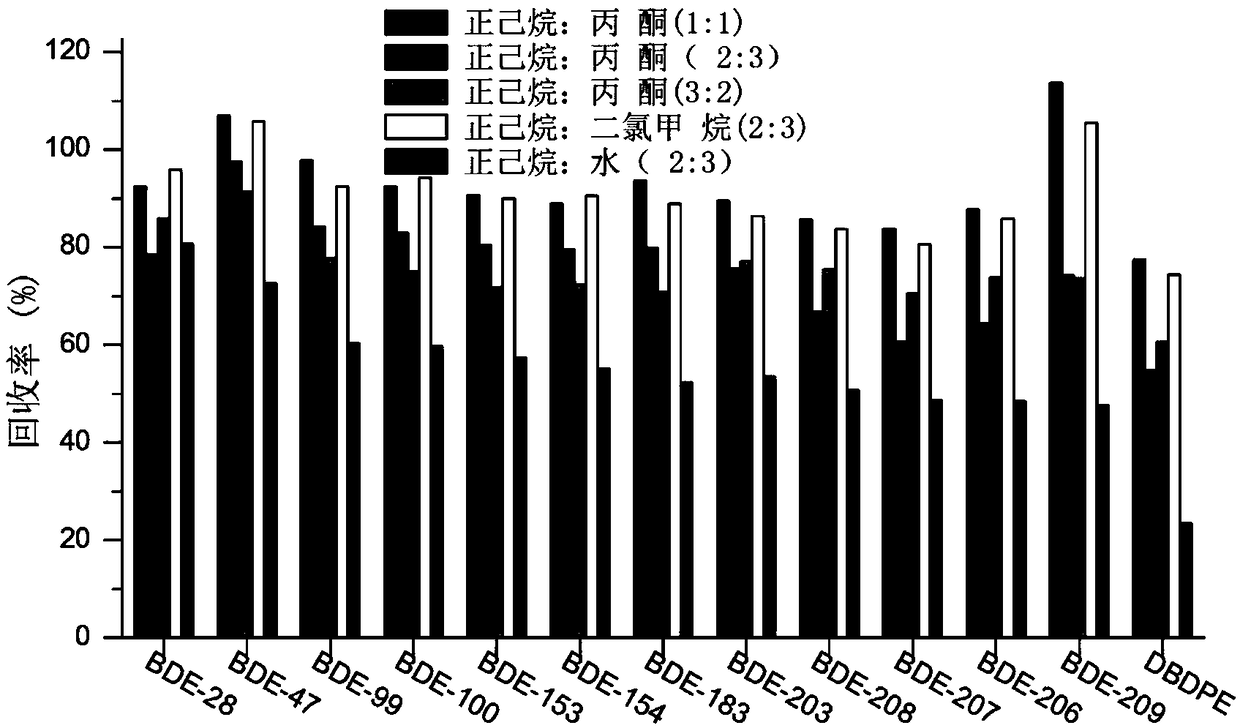

[0065] This example focuses on the microwave-assisted extraction of 13 brominated flame retardants in poultry eggs, and optimizes the conditions of the microwave-assisted extraction.

[0066] Step 1: Wash the surface of the egg, dry it in the air, remove the shell, mix the egg yolk and egg white, freeze it at -20°C to become solid, then place it in a freeze dryer, and vacuum freeze-dry it at -55°C for 24 hours. Grind into powder, mix 1.0g of egg samples with 5.0g of anhydrous sodium sulfate, completely transfer to a 100ml polytetrafluoroethylene extraction tube, add 13 kinds of standard samples (50ng / g) of the analyte, shake and mix, Equilibrate for 3h.

[0067] Step 2: Add 30ml of n-hexane / acetone (1 / 1, v / v) mixed solution, n-hexane:acetone (volume ratio, 2:3) mixed solution, n-hexane : acetone (volume ratio, 3:2) mixture, n-hexane: dichloromethane (volume ratio, 2:3) mixture and n-hexane: water (volume ratio, 2:3) mixture, microwave extraction at 110 ° C 20min, cooled to r...

Embodiment 3

[0074] This embodiment focuses on the pretreatment technology of 13 kinds of brominated flame retardants in poultry eggs, and the proportion of acidic silica gel is selected according to the fat content of the actual sample. Since the fat content of duck eggs is relatively higher than that of chicken eggs, the purification effect is improved and the amount of acidic silica gel is increased.

[0075] Step 1: Buy domestic duck eggs from a farmer’s home in an electronic dismantling concentration area, put them in an ice box and take them back to the laboratory, remove the egg shells, put them in a stainless steel bowl and use a glass rod to stir the egg white and egg yolk evenly, and freeze them at -20°C. Solid state, use a freeze dryer to freeze-dry, accurately weigh 2.0g of the sample, add an appropriate amount of anhydrous sodium sulfate, and grind evenly. Completely transfer to a microwave extraction tube, add 30ml of n-hexane / acetone (50 / 50, v / v) mixture, extract by microwav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com