Method for separating or analyzing phenolic acid compound from burdock

A technology for phenolic acids and compounds, applied in the field of active ingredient separation, can solve the problems of unstable and time-consuming derivatization of phenolic acid substances, and achieve the effects of improving duty cycle and sensitivity, large peak capacity, and stable derivatization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] (1) Preparation of the test solution:

[0082] The burdock leaves were sliced and dried into dry powder, then refluxed with 70% ethanol to extract for 3 hours, then added 0.15% of the total volume of hydrochloric acid to extract twice, mixed and concentrated under reduced pressure at 40°C, and then frozen Dry, add volume concentration and be mixed with the chromatographic methanol of 80% need testing solution;

[0083] (2) Prepare standard stock solution by reference product:

[0084] Weigh 3,4-dihydroxybenzoic acid, 2,5-dihydroxybenzoic acid, trans-p-coumaric acid, quimaric acid, vanillic acid, caffeic acid, trans-ferulic acid, sinapinic acid, all with volume concentration 80% chromatographic methanol is prepared as a standard stock solution with a substance concentration of 100ppm;

[0085] (3) Preparation of mixed standard solution:

[0086] Accurately measure the standard stock solution of 8 kinds of phenolic acid compounds, use described 80% chromatographic me...

Embodiment 2

[0090] Adopt the operation process as embodiment 1, wherein:

[0091] The chromatographic conditions of high performance liquid chromatography are as follows:

[0092] The size is 2.1mm×100mm, 3.0μm C18 column, the mobile phase is composed of mobile phase A and mobile phase B, wherein mobile phase A is an aqueous solution containing 0.1% formic acid, mobile phase B is methanol or acetonitrile, and the gradient is carried out under the following conditions Elution: 0~0.05min, 5%~35% mobile phase B; 0.05~15min, 35%~55% mobile phase B; 15~25min, 55%~100% mobile phase B; volume flow rate is 0.15mL. min -1 ; The injection volume is 5 μL; min -1 ; Ion mobility spectrometry conditions are as follows:

[0093]

[0094]

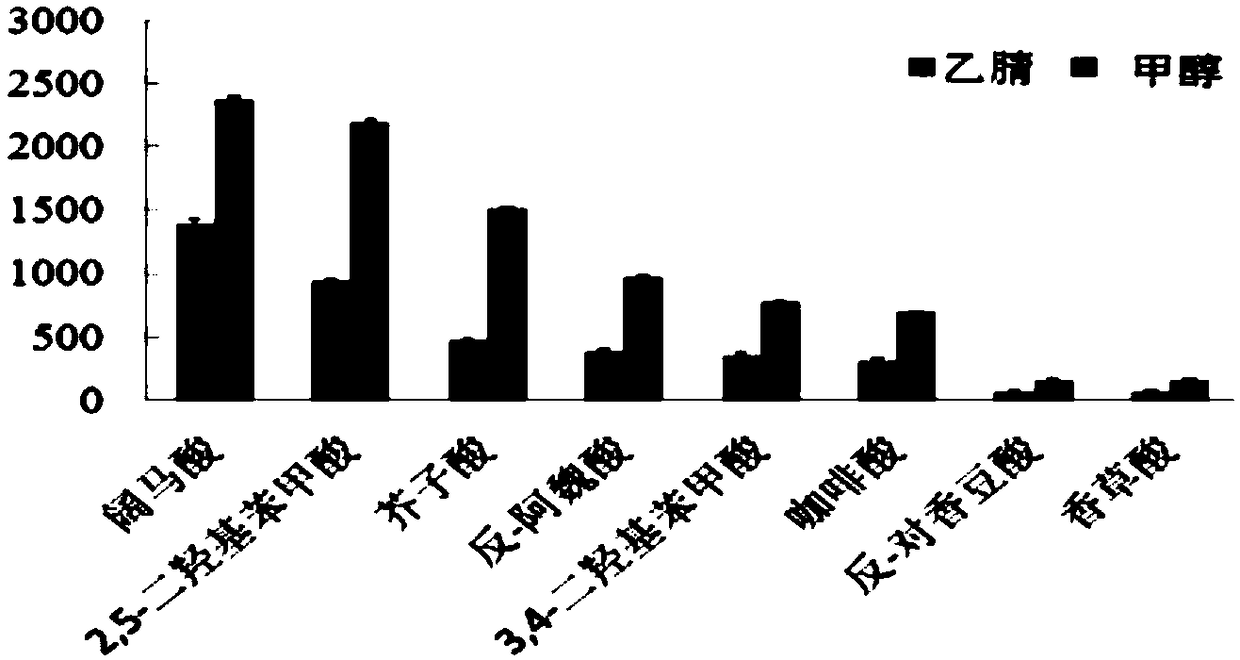

[0095] The signal-to-noise ratio of the obtained ion mobility spectrum was analyzed to obtain the following figure 1 In the statistical results shown, in each group of columns in the figure, the column on the left is acetonitrile, and the column on the righ...

Embodiment 3

[0097] Use the operation process as embodiment 1, wherein:

[0098] The chromatographic conditions of the high-performance liquid chromatography are as follows: the specification is 2.1mm×100mm, 3.0μm C18 column, the mobile phase is composed of mobile phase A and mobile phase B, wherein mobile phase A is 0.1% formic acid aqueous solution or 0.1% acetic acid aqueous solution , the mobile phase B is methanol, and the following conditions are used for gradient elution: 0-0.05min, 5%-35% mobile phase B; 0.05-15min, 35%-55% mobile phase B; 15-25min, 55%-100 % mobile phase B; the volume flow rate is 0.15mL. min -1 ; The injection volume is 5 μL; the column temperature is 35°C; post-column replenishment is preferred, and the flow rate of the post-column replenishment solution is 0.1mL. min -1 ;

[0099] The ion mobility spectrometry conditions are as follows:

[0100]

[0101]

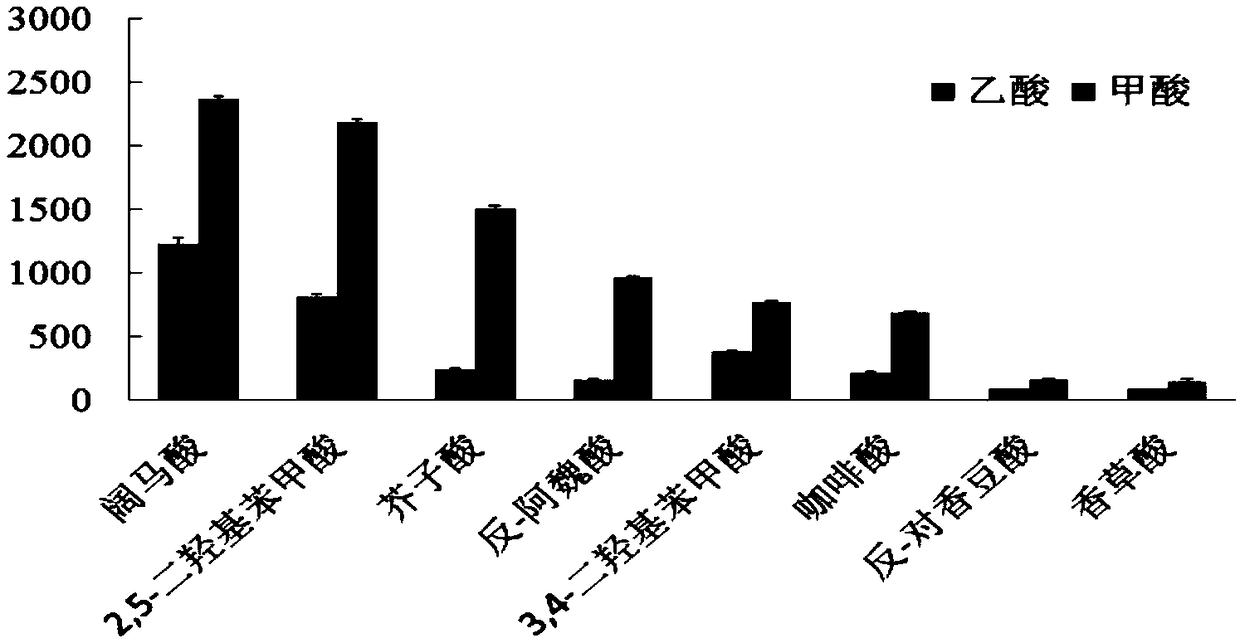

[0102] The signal-to-noise ratio of the obtained ion mobility spectrum was analyzed to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com