Environment-friendly wax removal agent and preparation method thereof

A wax remover and environmental protection technology, applied in the field of environmental protection wax remover and its preparation, can solve the problems of incomplete wax removal, slow wax removal rate, high toxicity, etc., so as to improve the scope of use and improve the lipophilic performance. , the effect of enhanced shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

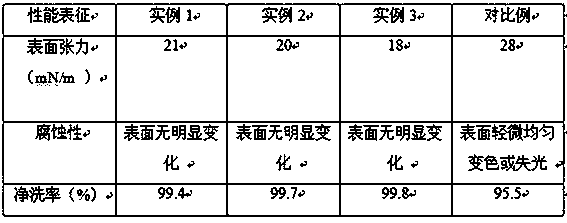

Examples

example 1

[0023] Take 5g of diatomaceous earth, add it to 100g of hexamethyldisilazane, stir at 50°C at 300r / min for 20min, cool to room temperature and filter to get the filter residue, wash the filter residue with deionized water 3 times and put it in a drying box , dried at 105°C to constant weight to obtain modified diatomite, take 10g peptone, 5g yeast powder, 5g sodium chloride, 0.2g magnesium sulfate, 5g potassium dihydrogen phosphate, 2g sodium nitrate, add 1.0L deionized Stir in water at 300r / min for 20min to obtain a culture solution. Take 200g of culture solution, 10g of oleic acid, 1g of wax-loving fungus, and 5g of modified diatomaceous earth, mix well, shake and cultivate at 150r / min at 25°C for 5 days, filter To obtain a filter cake, put the filter cake into a pulverizer after natural air drying, and pass through a 200-mesh sieve to obtain a cleaning agent. Take 5g cocamidopropyl betaine, 6g sodium N-acylaminocarboxylate, and 6g succinate Add sodium, 4g coconut oil fatty ...

example 2

[0025] Take 8g of diatomaceous earth, add it to 120g of hexamethyldisilazane, stir at 55°C at 300r / min for 25min, cool to room temperature and filter to obtain the filter residue, wash the filter residue 4 times with deionized water and place it in a drying oven , dried at 110°C to constant weight to obtain modified diatomite, take 12g peptone, 6g yeast powder, 6g sodium chloride, 0.2g magnesium sulfate, 6g potassium dihydrogen phosphate, 2g sodium nitrate, add 1.0L deionized In water, stir at 350r / min for 25min to obtain a culture solution. Take 250g of culture solution, 15g of oleic acid, 1g of wax-loving fungus, and 8g of modified diatomaceous earth, mix them evenly, shake and culture at 200r / min at 28°C for 6 days, filter To obtain a filter cake, air-dry the filter cake naturally and put it into a pulverizer to pulverize it, pass through a 200-mesh sieve to obtain a cleaning agent, take 6g of cocamidopropyl betaine, 8g of sodium N-acylaminocarboxylate, and 8g of succinate s...

example 3

[0027] Take 10g of diatomaceous earth, add it to 150g of hexamethyldisilazane, stir at 60°C at 400r / min for 30min, cool to room temperature and filter to get the filter residue, wash the filter residue with deionized water 5 times and put it in a drying box , dried at 120°C to constant weight to obtain modified diatomite, take 15g peptone, 8g yeast powder, 8g sodium chloride, 0.3g magnesium sulfate, 8g potassium dihydrogen phosphate, 3g sodium nitrate, add 1.2L deionized In water, stir at 400r / min for 30min to obtain a culture solution. Take 300g of culture solution, 20g of oleic acid, 2g of wax-loving fungus, and 10g of modified diatomaceous earth, mix well, shake and cultivate at 200r / min at 32°C for 8 days, filter To obtain a filter cake, air-dry the filter cake naturally and put it into a pulverizer to pulverize it, pass through a 200-mesh sieve to obtain a cleaning agent, take 8g cocamidopropyl betaine, 10g sodium N-acylaminocarboxylate, 10g succinate sulfonic acid Add so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com