Waterproof thermal insulation rheological material and preparation method thereof

A technology of waterproofing agent and pigment, applied in the direction of reflection/signal paint, coating, etc., can solve the problems of poor heat insulation effect and single function of waterproof paint, and achieve the effect of simple use method and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

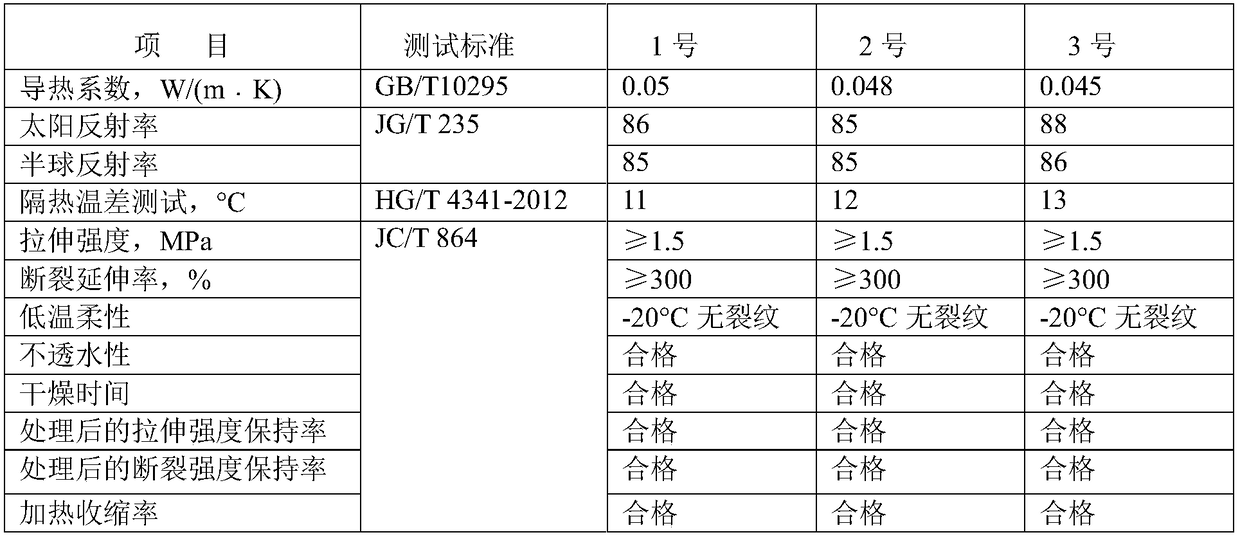

Examples

preparation example Construction

[0052] The method for preparing a waterproof and heat-insulating rheological material according to an embodiment of the second aspect of the present invention includes the following steps:

[0053] Step S1, mixing 150-200 parts by mass of the pigment and filler, 150-200 parts by mass of the first auxiliary agent and solvent, dispersing uniformly at high speed, grinding, and preparing a slurry for later use. During grinding, the mixture is ground to a fixed fineness.

[0054] Among them, the first auxiliary agent may be one or more of a dispersant, a wetting agent, a defoamer, hydroxyethyl cellulose, an antifreeze agent, a multifunctional auxiliary agent, and a solvent. In other embodiments of the present invention, other auxiliary agents can also be used to replace or add other different auxiliary agents, which can be appropriately selected and added according to needs, and the amount can also be adjusted according to needs, such as use environment, operating conditions and other co...

Embodiment 1

[0061] 1) Preparation of slurry

[0062] The following materials are calculated in parts by mass. Mix 200 parts by mass of deionized water, 100 parts by mass of rutile titanium dioxide, 50 parts by mass of ultrafine mica powder, 50 parts by mass of calcined kaolin and 16.5 parts by mass of additives, wherein the additives include dispersants ( D5045) 4 parts by mass, wetting agent (W-225) 2 parts by mass, defoamer (F111) 2 parts by mass, hydroxyethyl cellulose (QP-30000H) 2 parts by mass, antifreeze propylene glycol 5 parts by mass, more Functional additives (AMP-95) 1.5 parts by mass, add the above mixture to the disperser, disperse uniformly at high speed, and then grind it to the specified fineness by a sand mill to prepare a slurry for later use.

[0063] 2) Preparation of waterproof and thermal insulation rheological materials

[0064] The following materials are calculated in parts by mass. Add 160 parts by mass of elastic pure acrylic emulsion (Shanghai Jiu Optimal Engineerin...

Embodiment 2

[0066] 1) Preparation of slurry

[0067] The following materials are based on parts by mass. Mix 200 parts by mass of deionized water, 80 parts by mass of rutile titanium dioxide, 80 parts by mass of ultrafine zinc oxide, 40 parts by mass of ultrafine mica powder, and 17 parts by mass of additives, wherein the additives include 5 parts by mass of dispersant (D5045), 2 parts by mass of wetting agent (W-225), 2 parts by mass of defoamer (F111), 1.5 parts by mass of hydroxyethyl cellulose (QP-30000H), 5 parts by mass of propylene glycol, and Multifunctional auxiliary agent (AMP-95) 1.5 parts by mass, add the above-mentioned mixture to a disperser to evenly disperse it, grind it to the specified fineness with a sand mill, and prepare a slurry for later use.

[0068] 2) Preparation of rheological materials for waterproof and thermal insulation

[0069] The following materials are calculated in parts by mass, add 80 parts by mass of pure acrylic emulsion (Shanghai Jiu Optimal Engineering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com