PEG type thermosensitive hydrogel three-dimensional cell scaffold as well as preparation method and application thereof

A temperature-sensitive hydrogel and three-dimensional cell technology, applied in the field of PEG-based temperature-sensitive hydrogel three-dimensional cell scaffolds and their preparation, can solve the problems of restricting the application of hydrogel scaffolds, severe syneresis, refractory degradation, etc., and achieve good temperature sensitivity , the degree of syneresis is small, and the preparation method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a preparation method and application of a PEG-based thermosensitive hydrogel three-dimensional cell scaffold, which includes the following steps:

[0032] (1) Weigh 2.2371g of 2-methyl-2-acrylic acid-2-(2-methoxyethoxy)ethyl ester, 0.5462g of oligoethylene glycol methyl ether methacrylate, N,N'- Put 0.0431g of methylenebisacrylamide and 0.0284g of sodium lauryl sulfate in a 250mL three-necked round bottom flask, add 100mL of distilled water to dissolve, and continuously blow nitrogen to remove oxygen. After 1h, raise the temperature to 70°C, dissolve 0.0810g of initiator potassium persulfate in 5mL of distilled water, add it to the above solution, keep the nitrogen atmosphere, and continue the reaction for 5h to obtain PEG-based thermosensitive nanogel;

[0033] (2) The PEG-based thermosensitive nanogel obtained in step (1) was dialyzed for 7 days, and the water was changed 3 times a day to remove residual reactants, electrolytes and by-products...

Embodiment 2

[0043] This embodiment provides a preparation method and application of a PEG-based thermosensitive hydrogel three-dimensional cell scaffold, which includes the following steps:

[0044] (1) Weigh 2.3664g of 2-methyl-2-acrylic acid-2-(2-methoxyethoxy)ethyl ester, 0.3368g of oligoethylene glycol methyl ether methacrylate, N,N'- Put 0.0431g of methylenebisacrylamide and 0.0284g of sodium lauryl sulfate in a 250mL three-necked round bottom flask, add 100mL of distilled water to dissolve, and continuously blow nitrogen to remove oxygen. After 1h, raise the temperature to 70°C, dissolve 0.0810g of initiator potassium persulfate in 5mL of distilled water, add it to the above solution, keep the nitrogen atmosphere, and continue the reaction for 5h to obtain PEG-based thermosensitive nanogel;

[0045] (2) The PEG-based thermosensitive nanogel obtained in step (1) was dialyzed for 7 days, and the water was changed 3 times a day to remove residual reactants, electrolytes and by-products...

Embodiment 3

[0047] This embodiment provides a method for preparing a PEG-based thermosensitive hydrogel three-dimensional cell scaffold, which includes the following steps:

[0048] (1) Weigh 2.5004g of 2-methyl-2-acrylic acid-2-(2-methoxyethoxy)ethyl ester, 0.1260g of oligoethylene glycol methyl ether methacrylate, N,N'- Put 0.0431g of methylenebisacrylamide and 0.0284g of sodium lauryl sulfate in a 250mL three-necked round bottom flask, add 100mL of distilled water to dissolve, and continuously blow nitrogen to remove oxygen. After 1h, raise the temperature to 70°C, dissolve 0.0810g of initiator potassium persulfate in 5mL of distilled water, add it to the above solution, keep the nitrogen atmosphere, and continue the reaction for 5h to obtain PEG-based thermosensitive nanogel;

[0049] (2) The PEG-based thermosensitive nanogel obtained in step (1) was dialyzed for 7 days, and the water was changed 3 times a day to remove residual reactants, electrolytes and by-products. After purifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

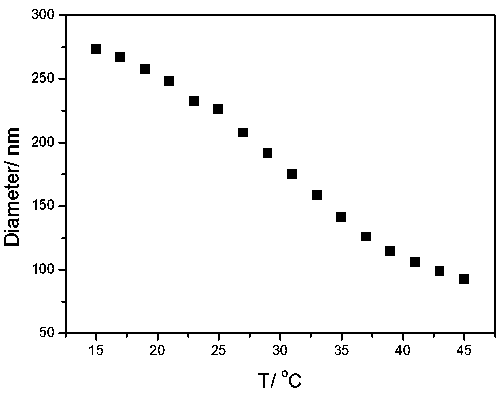

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com