Preparation and application method of amino mold plastic abrasives for aircraft coating layer removal

An amino molding compound and coating removal technology, which can be used in grinding/polishing equipment, grinding devices, manufacturing tools, etc. to achieve non-destructive removal, cost-effectiveness, and strong controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

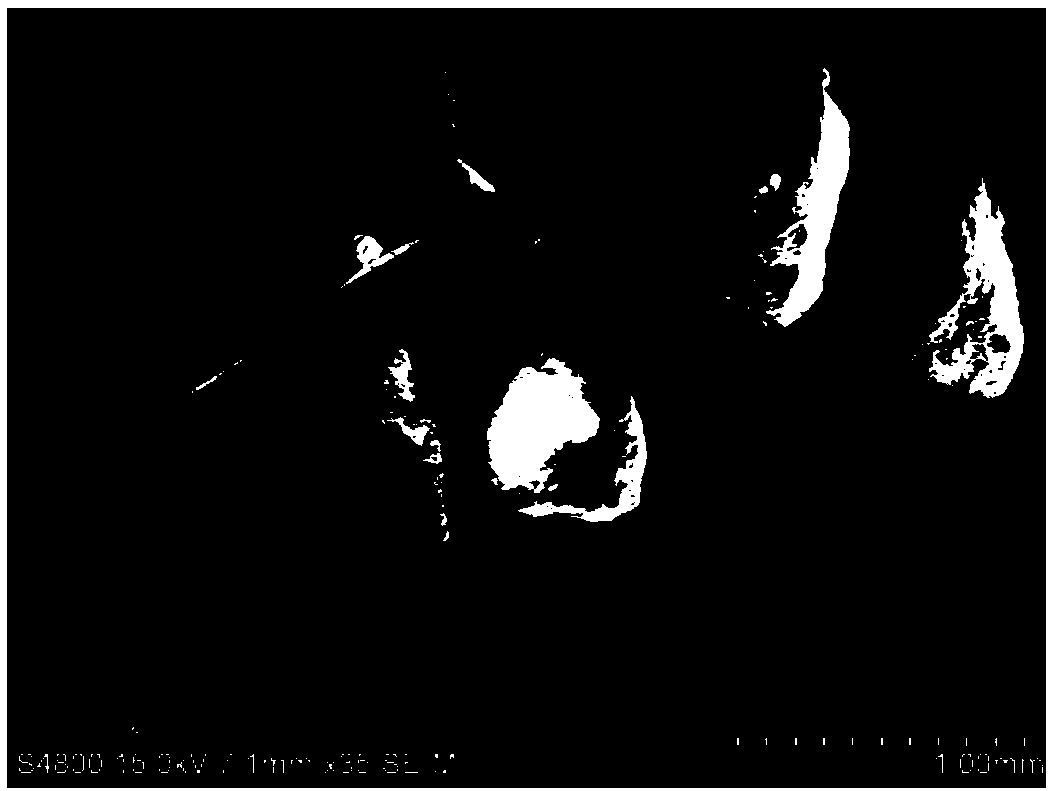

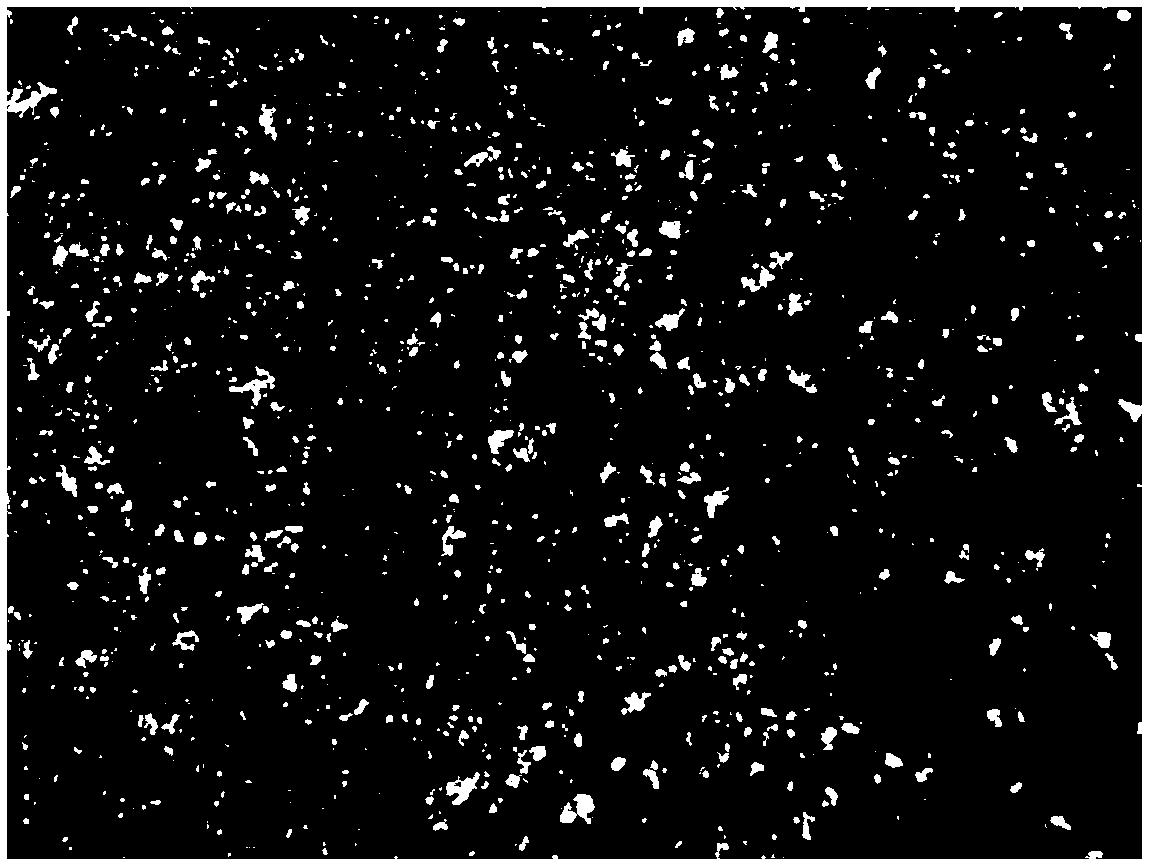

[0040]A method for preparing amino molding compound abrasives for aircraft coating removal. Part of the equipment used includes blade plastic crushers, turbine pulverizers, vibrating screens, ball mills, and sandblasting machines. product. The aircraft coating is an aircraft skin surface coating, and the base material is a 2024-T3 aluminum alloy plate. Amino molding compound abrasive, its main chemical composition is C and O.

[0041] Specific steps are as follows:

[0042] 1. Broken amino molding compound

[0043] Put the amino molding compound with a Mohs hardness of 3.5~4.5 into the blade plastic crusher for crushing. The pairing ratio of the fixed blade and the moving blade of the crusher is 2:3, and the adjustment gap between the blades is 1~5mm. The blade hardness is HRC52~58, and the sieve plate aperture of the crusher is Ø8.0~Ø12.0mm.

[0044] 2. Grinding and screening of amino molding compound particles

[0045] Put the crushed amino molding compound particles in...

Embodiment 2

[0051] The difference between this embodiment and the first embodiment is that the pairing ratio of the fixed blade and the movable blade of the crusher is 4:6, and the operation is the same as that of the first embodiment.

example 1

[0053] Step 1. Amino molding compound is broken

[0054] Put the amino molding compound with a Mohs hardness of 4.0 into a blade-type plastic crusher for crushing. The crusher has 4 fixed blades and 6 moving blades. The adjustment gap between the control blades is 4mm. The hardness of the blades is HRC56. The mesh diameter is Ø8.0mm.

[0055] Step 2. Abrasive crushing and screening

[0056] Put the amino molding plastic particles crushed by the crusher into the turbine crusher for crushing. The rotor diameter of the crusher is 500mm, and the turbine speed is 3250r / min. Finally, the crushed particles are put into the vibrating screen for classification and screening. After screening The particle size grades are 60 mesh.

[0057] Step 3, preparation of abrasive

[0058] Mixing the screened particles with a particle size grade of 20-30 mesh, 30-40 mesh, 40-50 mesh and 50-60 mesh according to a certain mass percentage to obtain a polishing abrasive. The specific ratio is: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com