A Laser Scanning Method for Improving Interlaminar Strength and Reducing Warpage

A technology of laser scanning and laser scanning path, which is applied in the direction of improving energy efficiency, improving process efficiency, processing and manufacturing, etc., can solve the problems of interlayer strength difference, warpage and deformation, etc., to improve interlayer strength and reduce warpage The amount of deformation, the effect of enhanced interconnectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

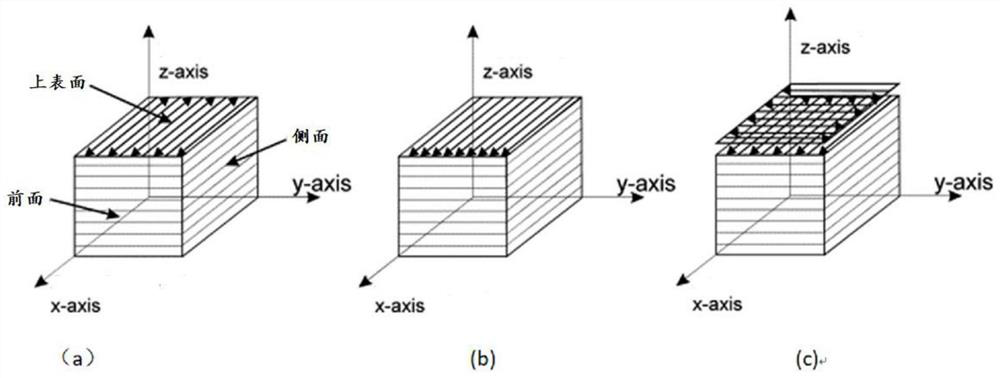

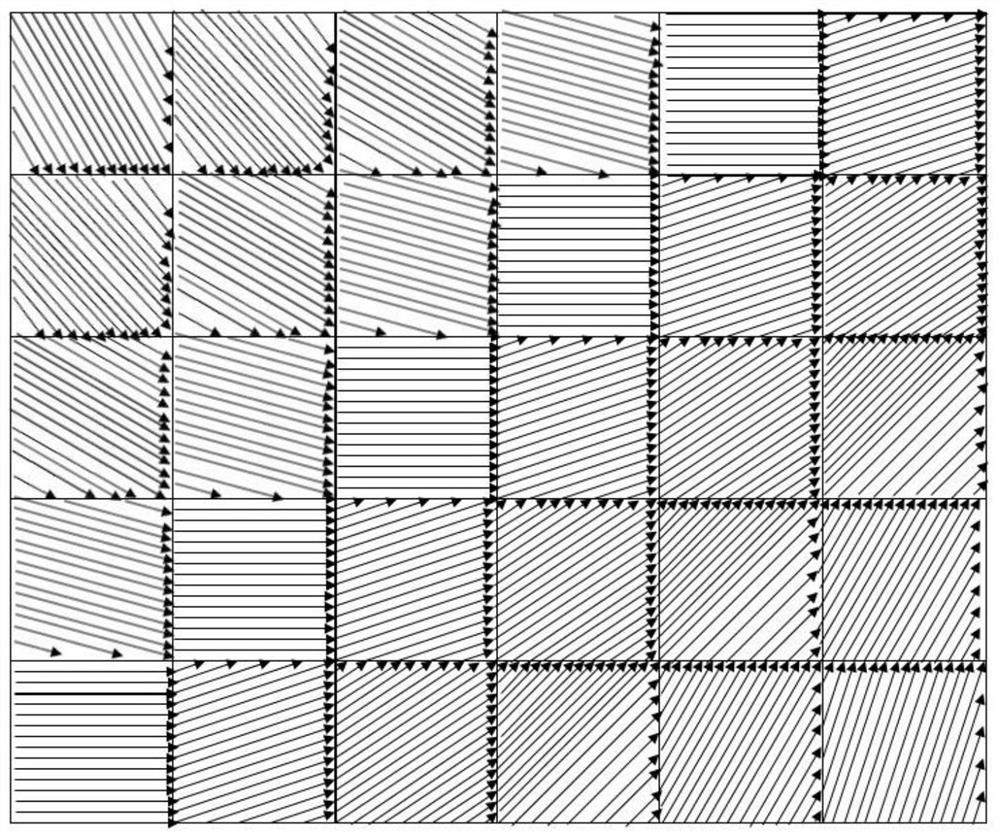

[0044] combine image 3 , a laser scanning method for improving interlayer strength and reducing warping deformation includes the following steps: Step 1: Divide a powder layer into 6*5 subsections (each small square in the figure is a subsection), using The first sub-section is scanned by laser in a unidirectional scanning manner, so that the first sub-section includes a plurality of laser scanning paths with a first angle (as shown by arrows in the sub-section in the figure), and each of the laser beams Each scanning path includes a start point and an end point; step 2: laser scanning is performed on a second sub-section adjacent to the first sub-section in a unidirectional scanning manner, so that the second sub-section includes multiple laser scanning paths with a second angle , each of the laser scanning paths includes a start point and an end point, wherein the second angle is different from the first angle; Step 3: use the scanning method of step 2 to scan the 3-30 sub-...

Embodiment 2

[0048] A laser scanning method for reducing warping deformation includes the following steps: Step 1: Laser scanning the first layer of powder in a unidirectional scanning manner, so that a layer of powder includes multiple laser scanning paths with a first angle, each Each of the laser scanning paths includes a starting point and an end point; Step 2: Laser scanning the second layer of powder in a unidirectional scanning manner, so that the second layer of powder includes a plurality of laser scanning paths with a second angle, each of the The laser scanning paths all include a start point and an end point, wherein the second angle is different from the first angle; Step 3: scan the remaining powder layers in turn, so that each layer of powder includes multiple laser scanning paths with a certain angle, each Each of the laser scanning paths includes a start point and an end point, wherein the angle of the laser scanning path of each layer of powder is different from the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com