Semiconductor structure and forming method thereof

A semiconductor and conformal technology, applied in semiconductor devices, microstructure technology, microstructure devices, etc., can solve the problem of easily increasing the difficulty of MEMS device process, achieve the improvement of interconnection capability, raise the interconnection surface, and reduce the difficulty of the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

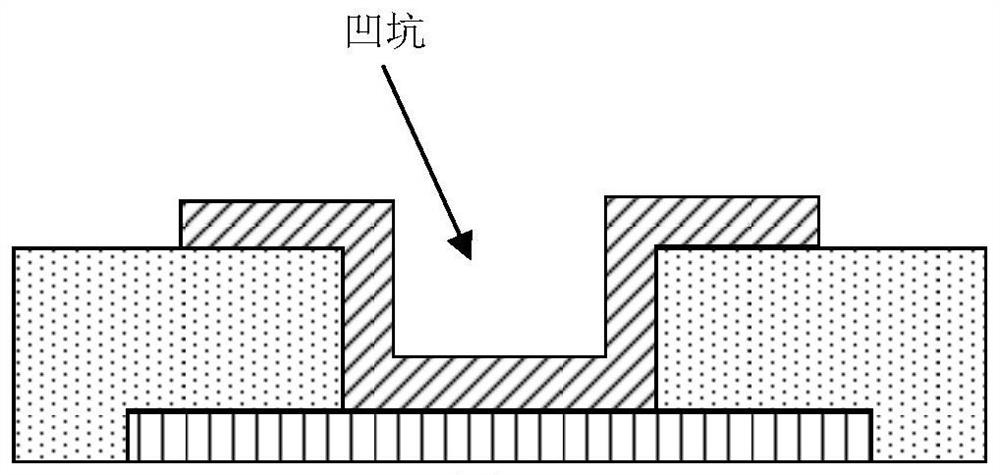

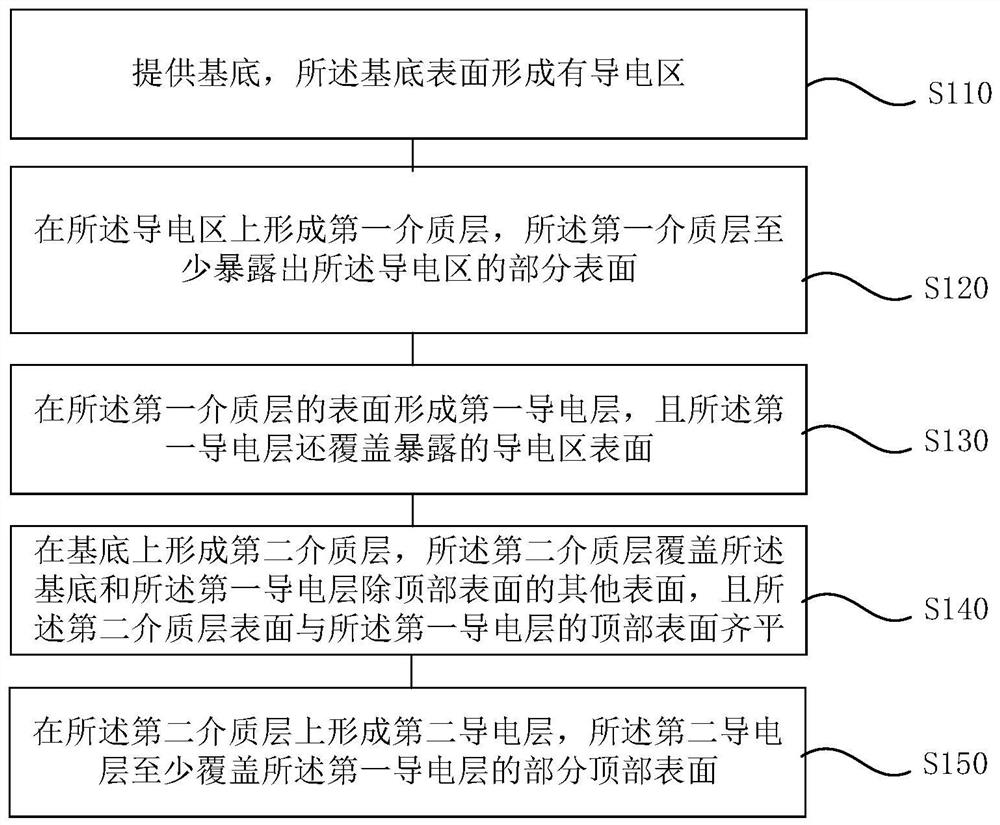

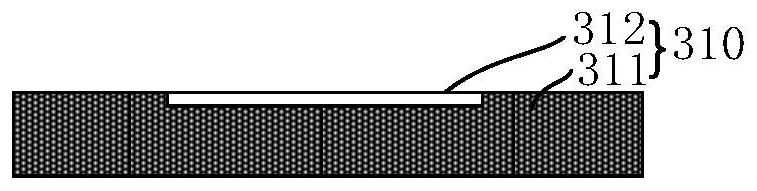

[0045] In sensing MEMS devices or optical MEMS devices, such as microactuators, the interconnection between semiconductor structures usually uses interconnection processes such as metal interconnection. It is an important process, and its process characteristics have an important impact on the subsequent process of the integrated circuit and the performance of the resulting circuit. In the traditional interconnection process, in order to ensure the interconnection between the two conductive layers, it is usually necessary to set a via hole with a larger size. The vias interconnect the second-level metal with the first-level metal. The via hole with the above-mentioned larger size will appear as follows after the second conductive layer is filled. figure 1 If the pits shown are used directly for subsequent interconnection, the pits will have too many turns, which will affect the difficulty of subsequent interconnection processes. If the pit is filled, the pit will require sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com