Method for forming metal interconnect structure

A metal interconnection structure and metal layer technology, which is applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., to achieve the effects of small damage, reduced damage, and reduced by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

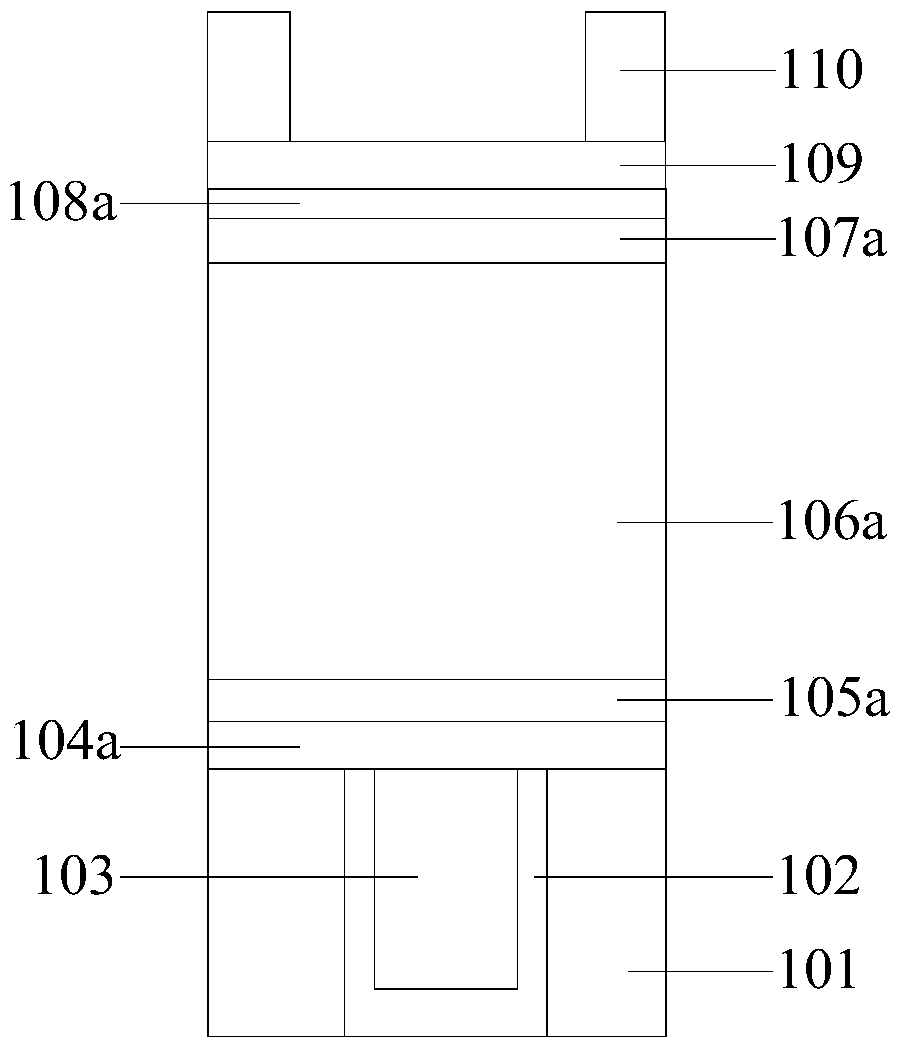

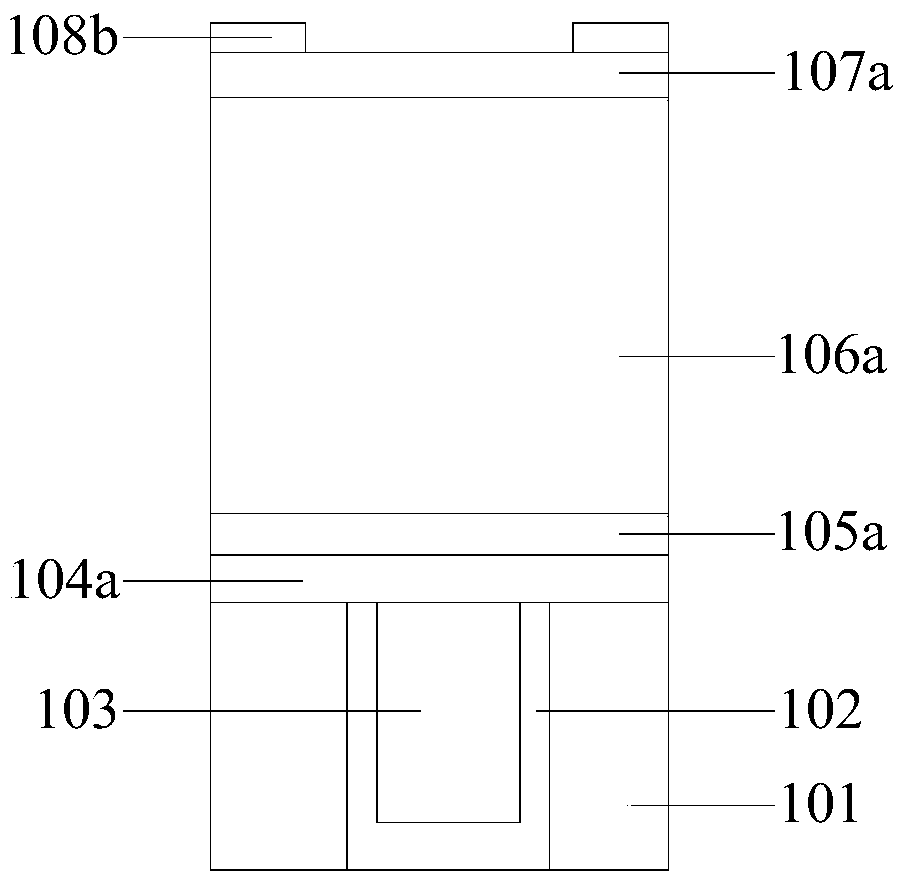

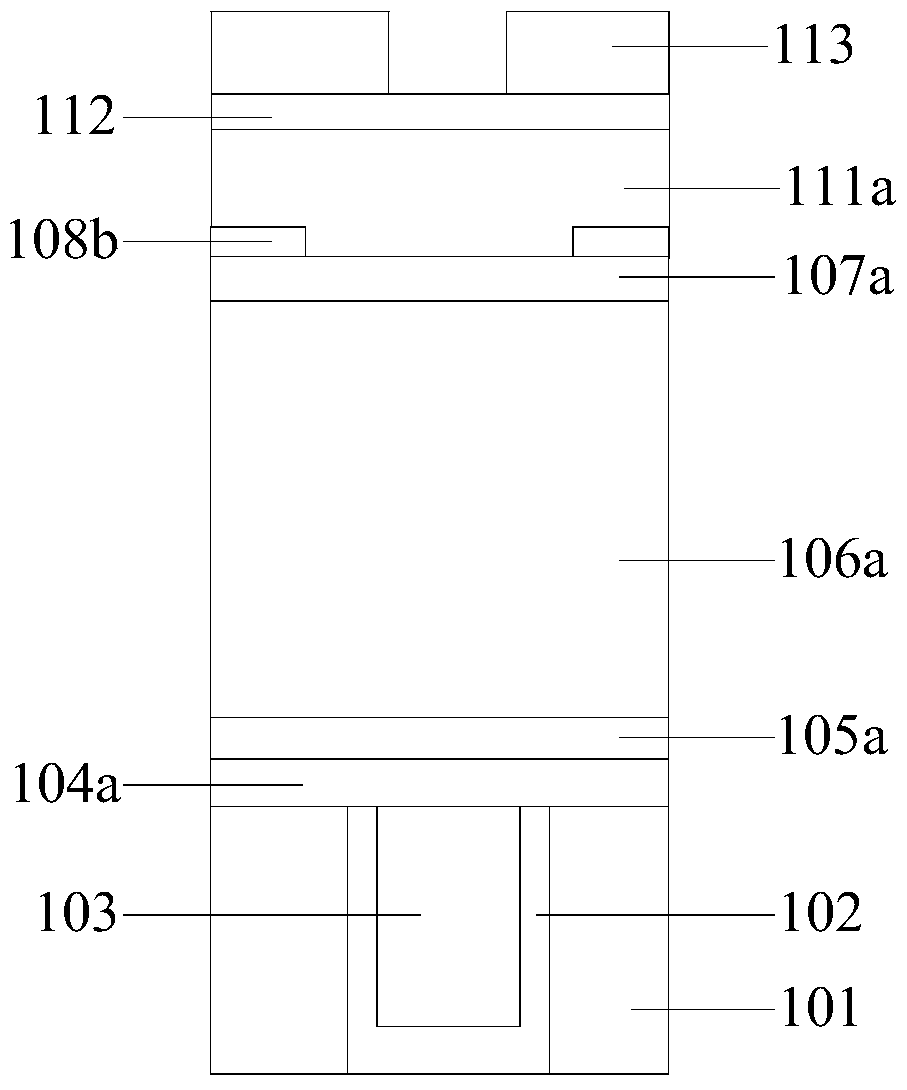

Image

Examples

Embodiment Construction

[0031] In the conventional method, after the contact hole is formed, a repair process is performed. However, in the existing methods, repairing treatment is usually carried out at a temperature of 20° C. to 60° C. The temperature condition of 20°C to 60°C is based on two considerations: on the one hand, it is generally believed that repairing at a higher temperature will have adverse effects on other semiconductor structures; on the other hand, the higher the temperature, the corresponding process The thermal budget is higher, resulting in increased process costs. Therefore, the existing methods usually carry out repair treatment at slightly higher than room temperature. Moreover, generally those skilled in the art do not think that the repair process after forming the contact hole is related to the electromigration problem of the finally formed metal interconnection structure.

[0032] However, after research and analysis, the present invention increases the temperature use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com