Preparation method of high performance precoated sand

A coated sand, high-performance technology, applied in the field of foundry molding, can solve the problems of short high temperature heat resistance time and low high temperature resistance performance, and achieve the effects of increasing density, improving softness, and reducing the tendency of formation and expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

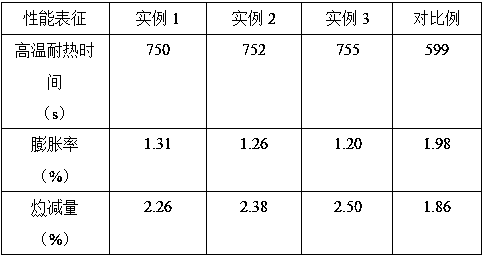

Examples

Embodiment Construction

[0019] In parts by weight, weigh 20-30 parts of silicon nitride powder, 10-15 parts of fly ash, 5-8 parts of alumina powder, 2-6 parts of silicon carbide powder, and 20-40 parts of deionized water, Mix silicon nitride powder, fly ash, alumina powder and silicon carbide powder, and ball mill for 20-40 minutes to get mixed powder, add deionized water, put it in the mixer for 30-40 minutes, and trap the material for 20-40 minutes. After 24 hours, the blend was obtained, and it was molded after holding the pressure at 50-80MPa for 30-50s to obtain a green body block. After drying the green body block in an oven at 100-120°C for 8-12 hours, it was heated at 3°C / The heating rate is raised to 1000-1200°C for sintering at a high temperature and kept for 2-5 hours. After cooling with the furnace, it is crushed and passed through a 200-300 mesh sieve to obtain fillers; weigh 20-30 parts of silica sand, 4 to 10 parts of calcium stearate, 10 to 15 parts of phenolic resin, 1 to 3 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com