Perovskite composite oxide loaded platinum catalyst and preparation and application thereof

A composite oxide and platinum catalyst technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, hydroxyl compound preparation, organic compound preparation, etc., can solve rare problems and achieve good activity retention and catalyst Superior performance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

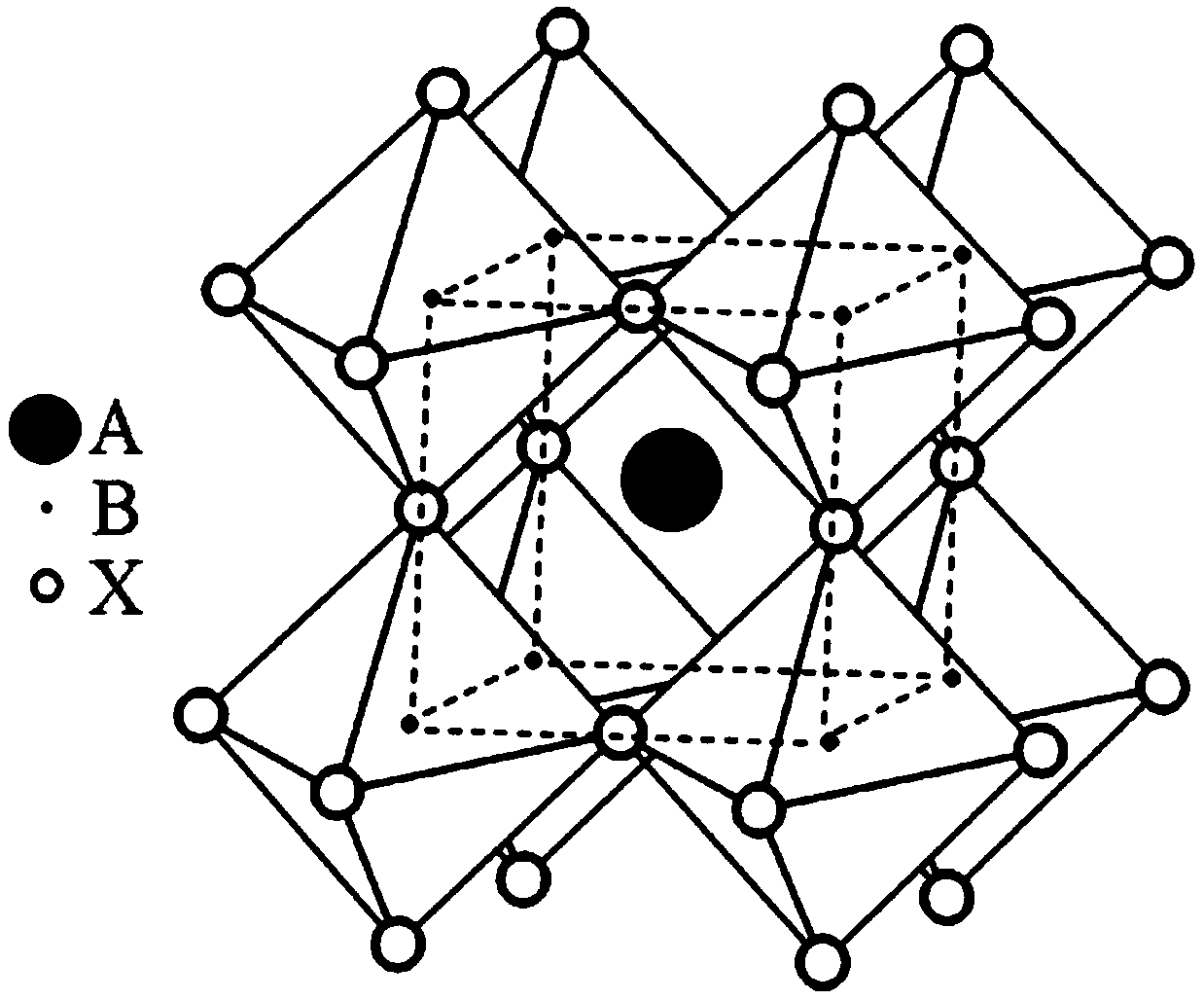

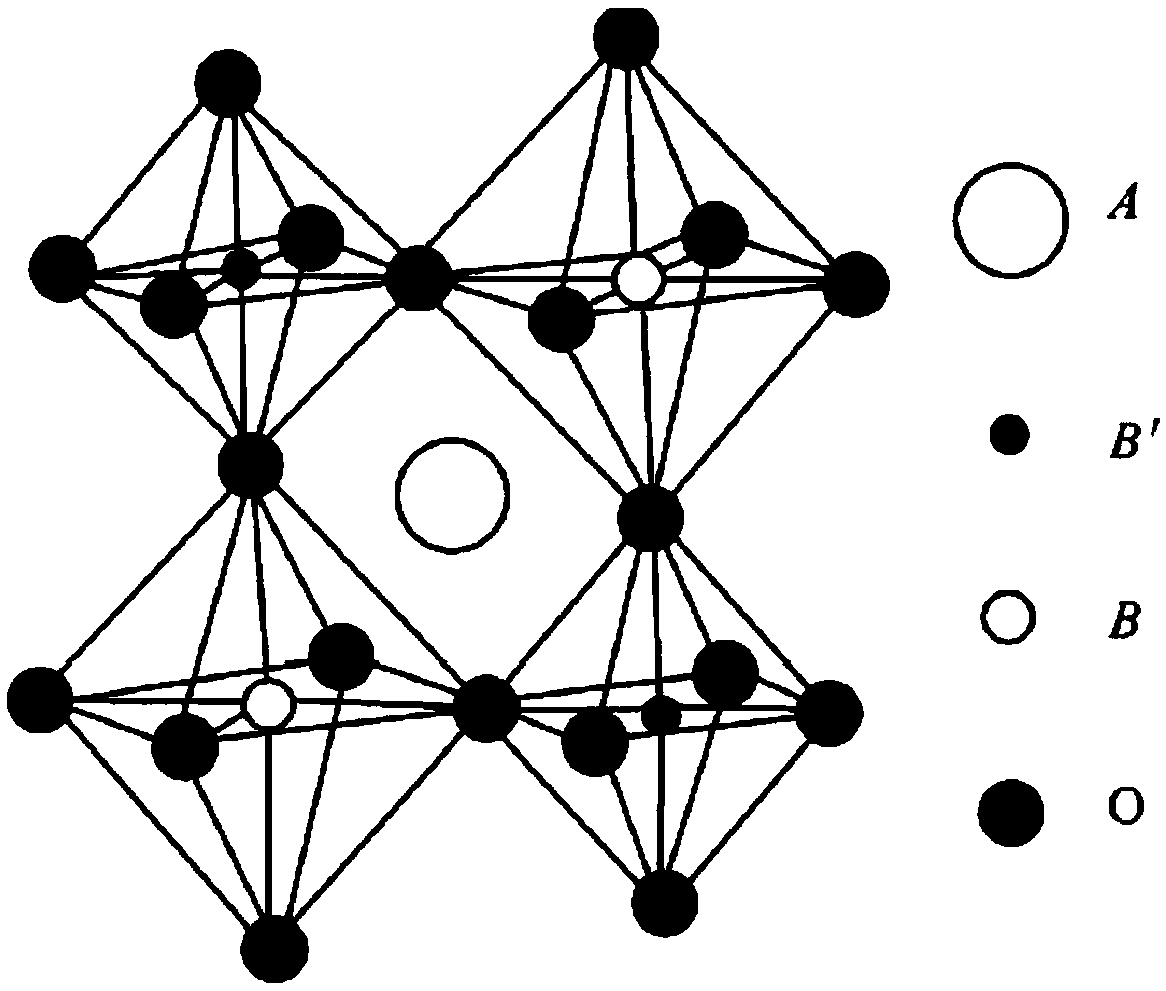

Method used

Image

Examples

Embodiment 1

[0028] a. Take 0.03mol citric acid as a complexing agent, add 0.015mol yttrium nitrate, 0.0045mol cobalt nitrate, and 0.0105mol ferric nitrate into a mixed solution, stir for 0.5 hours and add 1 gram of SBA-15 to the above solution, After stirring for 2 hours, transfer the above solution to a water bath at 90°C to continue stirring to form a gel, then put it in a drying oven at 140°C to dry, and then pre-baked it in a muffle furnace at 500°C for 4 hours and then raised it to 950°C. °C for another 6 hours.

[0029] b. After the roasting is completed, use 0.05 mol of sodium hydroxide solution (concentration of 2 mol / L) to remove silicon, stir for 35 hours, filter with suction, rinse with a large amount of deionized water, and dry in an oven at 80°C for 10 hours. The product is YCo 0.3 Fe 0.7 o 3 Perovskite type composite oxide.

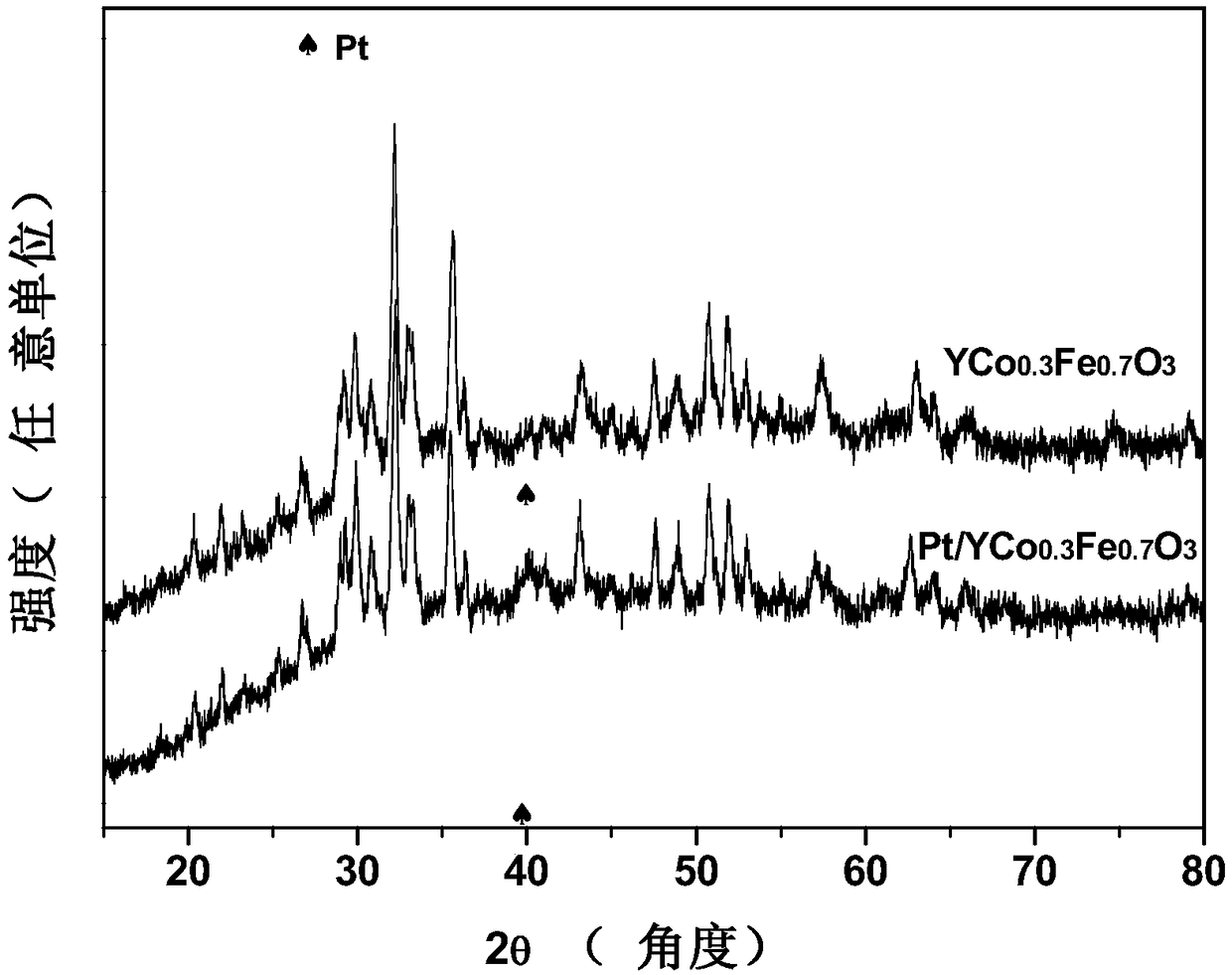

[0030] See attached image 3 , YCo prepared above 0.3 Fe 0.7 o 3 The perovskite-type composite oxide is characterized by wide-angle X-ray diffr...

Embodiment 2

[0039] a. Weigh 25 mg of the 5Pt / YCo prepared above 0.3 Fe 0.7 o 3 The platinum catalyst was treated in a vacuum oven at 90°C for 1 hour, followed by a pretreatment in 99.999% hydrogen at a temperature of 200°C for 2 hours.

[0040] b. Mix the above-mentioned pretreated catalyst with 0.5g of cinnamaldehyde in a mixed solution prepared by adding 9mL of isopropanol and 1mL of water, and pass in hydrogen gas with a purity of 99.999% and a pressure of 2.0MPa, in a constant temperature water bath at 90°C The catalytic hydrogenation reaction was carried out with electromagnetic stirring for 60 minutes.

[0041] C, after the hydrogenation reaction ends, its product is separated from the catalyzer, and its product is analyzed by gas chromatography, and its transformation rate is 98.9%, and the reaction rate is 5.93 (mol CAL · gPt -1 h -1 ), the selectivity of cinnamyl alcohol is 94.9%, the selectivity of phenylpropionaldehyde is 0.5%, and the selectivity of phenylpropanol is 4.6%...

Embodiment 3

[0043] Using 3Pt / YCo 0.3 Fe 0.7 o 3 Platinum catalyst (that is, the loading of Pt is 3%), the application in the liquid phase selective hydrogenation reaction of cinnamaldehyde, takes by weighing 40mg catalyst and 1.0g cinnamaldehyde, other conditions are the same as embodiment 2, react with gas chromatography after finishing Its product is analyzed, and its transformation rate is 54.8%, and reaction rate is 6.85 (mol CAL g Pt -1 h -1 ), the selectivity of cinnamyl alcohol is 93.3%, the selectivity of phenylpropanal is 4.6%, and the selectivity of phenylpropanol is 2.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com