Film-forming agent used for seed coating agent as well as preparation method and application thereof

A film-forming agent and dispersing agent technology, applied in the field of biological pesticide preparation, can solve the problems of unfavorable seed germination, easy to fall off into powder, poor fluidity of preparations, etc. The effect of short film time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

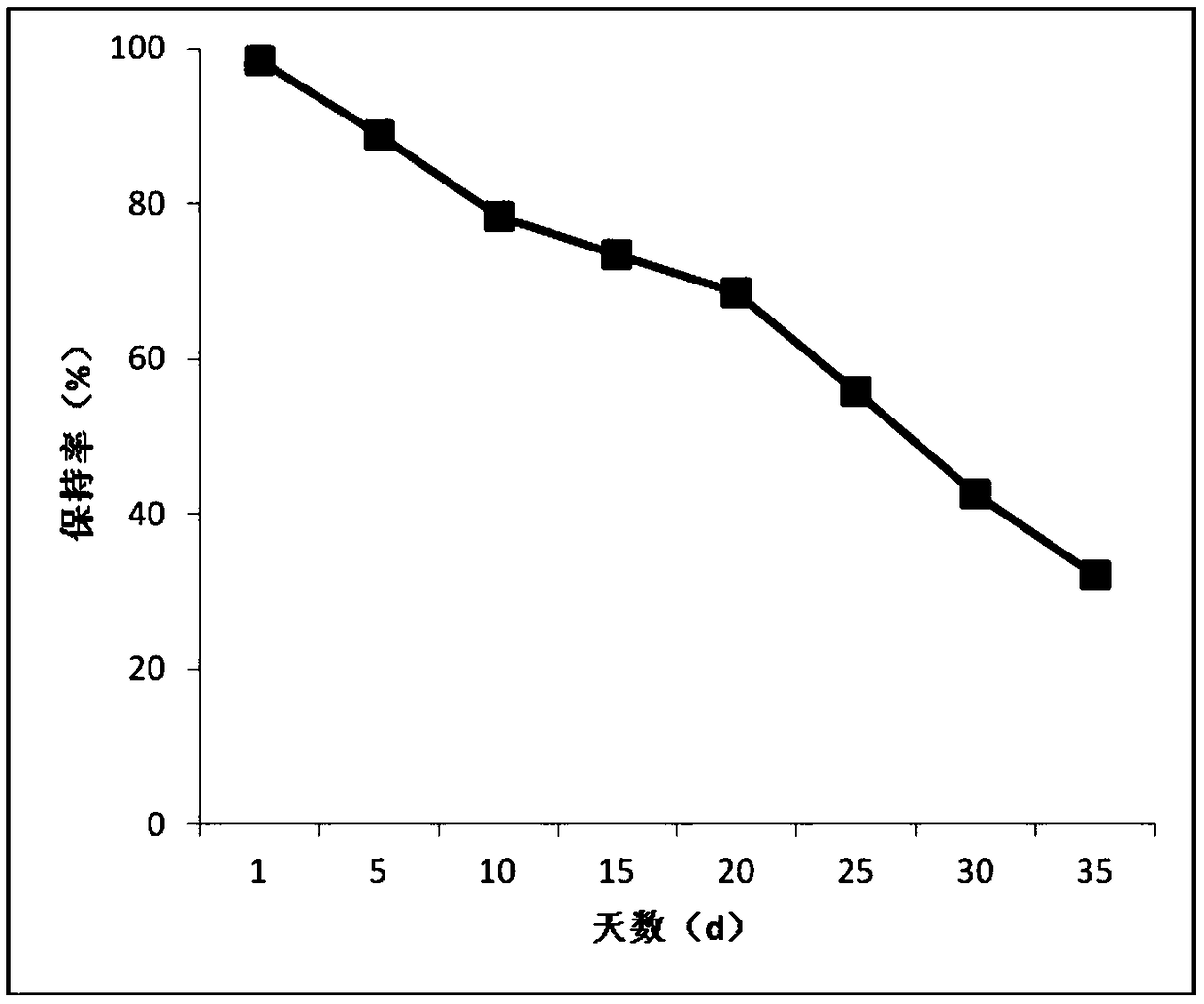

Image

Examples

Embodiment 1

[0028] The preparation method of polyvinyl alcohol blending modified film-forming agent, the steps are as follows:

[0029] Weigh 10 g of polyvinyl alcohol and mix it with 90 g of distilled water, heat and stir until completely dissolved to obtain 10% polyvinyl alcohol by mass fraction.

[0030] The polyvinyl alcohol used is PVA17-92.

[0031] The VAE emulsion was stirred in warm water at 50°C to prepare an emulsion with a mass fraction of 20% for later use.

[0032] Gum arabic, chitosan, gelatin, alginic acid and sodium carboxymethyl cellulose were respectively formulated into solutions with a mass fraction of 10%.

[0033] Mix 10% polyvinyl alcohol and 20% VAE emulsion (vinyl acetate-ethylene copolymer emulsion) with 10% gum arabic, chitosan, gelatin, alginic acid and sodium carboxymethyl cellulose solution at a ratio of 1:1:1 Specific mixing, colloid grinding for 10 minutes, adding 2% calcium lignosulfonate, and high-speed shearing at 12000r / min for 25 minutes to obtain a...

Embodiment 2

[0049] After mixing 10% polyvinyl alcohol, 20% VAE emulsion and 10% gum arabic solution according to the mass ratio in Table 2, the colloid mill was twisted for 10 minutes, and 2% calcium lignosulfonate was added. High-speed shearing for 25 minutes to obtain polyvinyl alcohol blended modified film-forming agents with different dosage ratios.

[0050] Table 2 The distribution ratio of different components of film-forming agent

[0051] group

[0052] 2. Performance evaluation of polyvinyl alcohol blended modified film-forming agent with different dosage ratios

[0053] According to the method in 1., the storage stability, film-forming property and seed germination rate of the film-forming agent of the polyvinyl alcohol blended modified film-forming agent with different dosage ratios were determined. The results are shown in Table 3.

[0054] Table 3 Properties of polyvinyl alcohol blended modified film formers with different dosage ratios

[0055] group

...

Embodiment 3

[0058] A compound seed coating agent for preventing and treating rice sheath blight, comprising the following components in percentage by weight:

[0059] Thiamethoxam 1.2%, Curculigoside 0.6%, Wuningmycin 0.2%, Forchlorfenuron 0.4%, Film-forming agent 8%, Dispersant 6%, Thickener 0.6%, Basic rhodamine 0.5%, Salicylic acid 0.05%, trace elements 0.07%, water balance.

[0060] The trace element is SiO 2 , CaO, and zinc sulfate in a mass ratio of 1:1:1.

[0061] The preparation method of described composite seed coating agent, the steps are as follows:

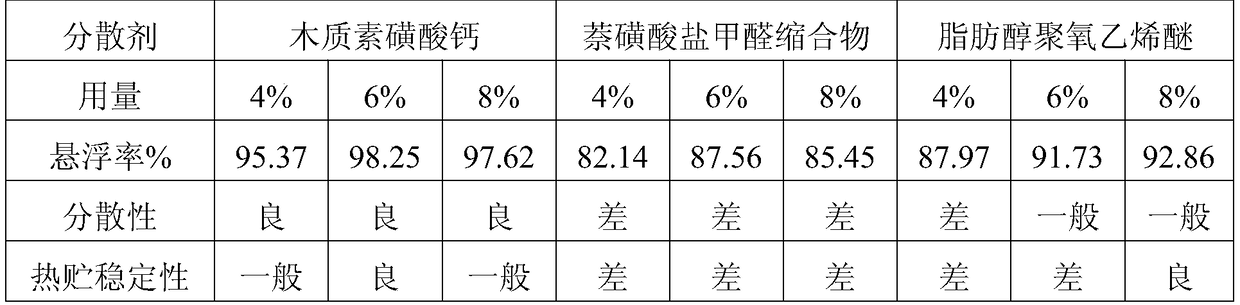

[0062] 10% polyvinyl alcohol, 20% VAE and 10% gum arabic were mixed at a mass ratio of 1:2:1, colloid milled for 10 minutes, 2% dispersant was added, high-speed shearing was performed at 12000r / min for 25 minutes, and 0.5 % alkaline rhodamine, dispersed on a high-speed shearing tissue disperser for 25 minutes; weighed liquid medicine, thickener, remaining dispersant, water, mixed at a high speed and sheared evenly, put into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com