Rapid detection method for heavy metal contents in children textiles and shoe parts based on XRF technology

A detection method and textile technology, applied in the field of chemical detection, can solve the problems of inaccurate detection results, low detection efficiency, time-consuming and labor-intensive, etc., and achieve the effect of simplifying sample pretreatment steps, saving detection time, and saving detection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a rapid detection method for heavy metal content in children's textiles, the specific steps are as follows:

[0042] Step 1. Sample pretreatment

[0043] Take the children's clothes with printed coating, take the coated part, first use the mixed solvent of n-hexane and acetone (volume ratio 4:1) to clean the oil stain on the surface, wash off the oil-soluble solvent on the cloth with ethanol, and let it dry naturally to obtain the desired Process the samples to be tested.

[0044] Step 2, XRF direct scanning

[0045] XRF is X-ray fluorescence spectrometry (X Ray Fluorescence). The XRF parameters described in Table 1 were used to test the samples to be tested.

[0046] Table 1 XRF direct scanning method test conditions

[0047]

[0048] Sampling was repeated 5 times, XRF direct scanning was performed, and the analysis report was as follows Figure 5 As shown, the heavy metal mass fraction detection results are shown in Table 2:

[0049] ...

Embodiment 2

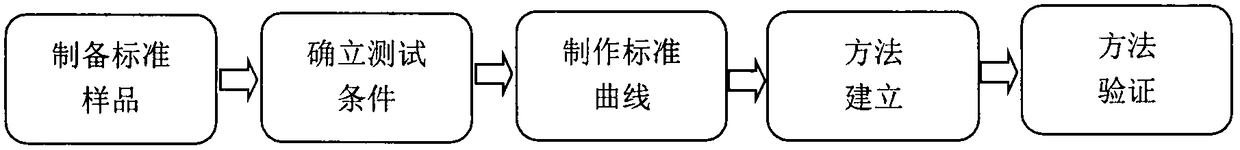

[0066] This embodiment provides a rapid detection method for heavy metal content in children's shoes parts, the process is as follows figure 1 As shown, the specific steps are as follows:

[0067] Step 1. Preparation of standard samples

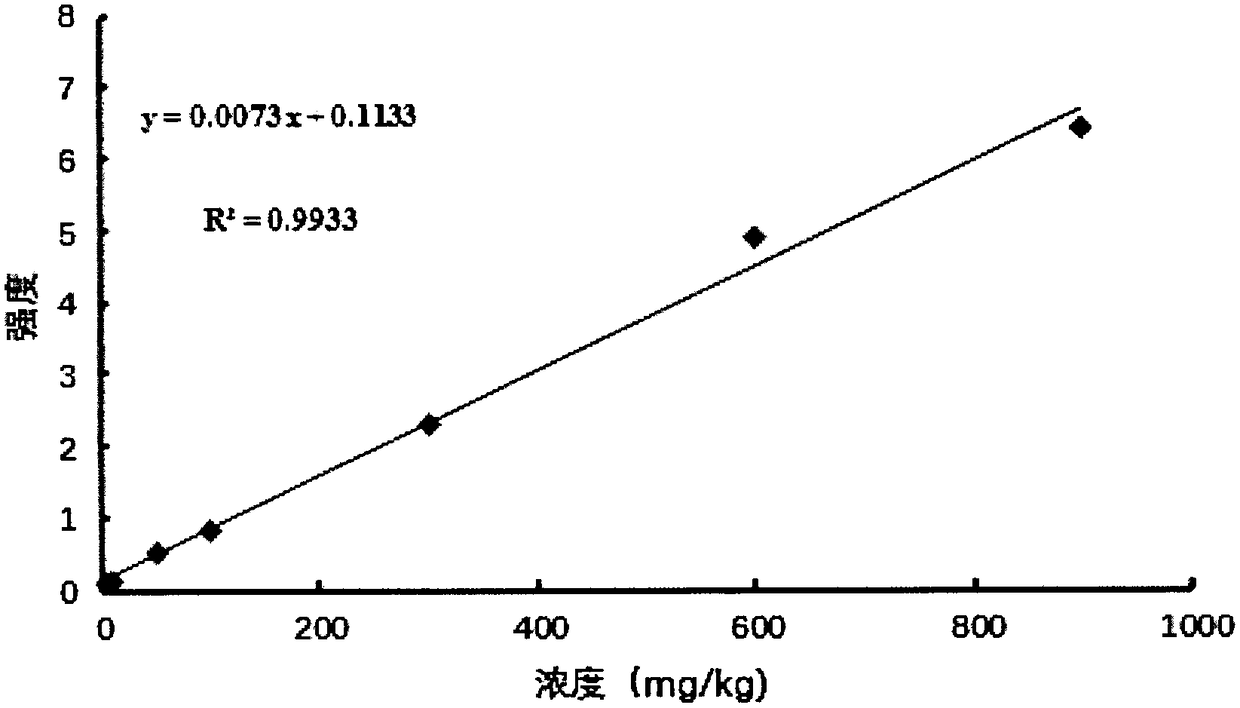

[0068] The heavy metal (lead, cadmium, arsenic) content of 0.01g ~ 9g solid powder is fully ground and mixed with 10kg PVC powder, after heating and melting, it is pressed into a sheet structure with a thickness of 0.8 ~ 1.5mm, and the heavy metal (lead, cadmium, arsenic) content of 1mg / kg, 2mg / kg, 3mg / kg, 4mg / kg, 5mg / kg, 10mg / kg, 50mg / kg, 90mg / kg, 100mg / kg, 300mg / kg, 600mg / kg, A series of standard samples of 900mg / kg.

[0069] Step 2. Sample pretreatment

[0070] Take children's shoe parts and use a precision plastic slicer to cut them. The thickness of the sample to be tested is precisely controlled to be consistent with the thickness of the standard sample. After exposing the distribution surface, clean it with a mixed solvent of n-hexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com