Method for preparing homoepitaxial double-sided MgO thin films based on middle-frequency sputtering

A homogeneous epitaxy and thin film technology, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem that the uniformity of the film surface cannot be guaranteed, the structure and morphology of the film are not ideal, and the film cannot be continuous Growth and other issues, to achieve the effect of ensuring uniformity and consistency, improving cost performance, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

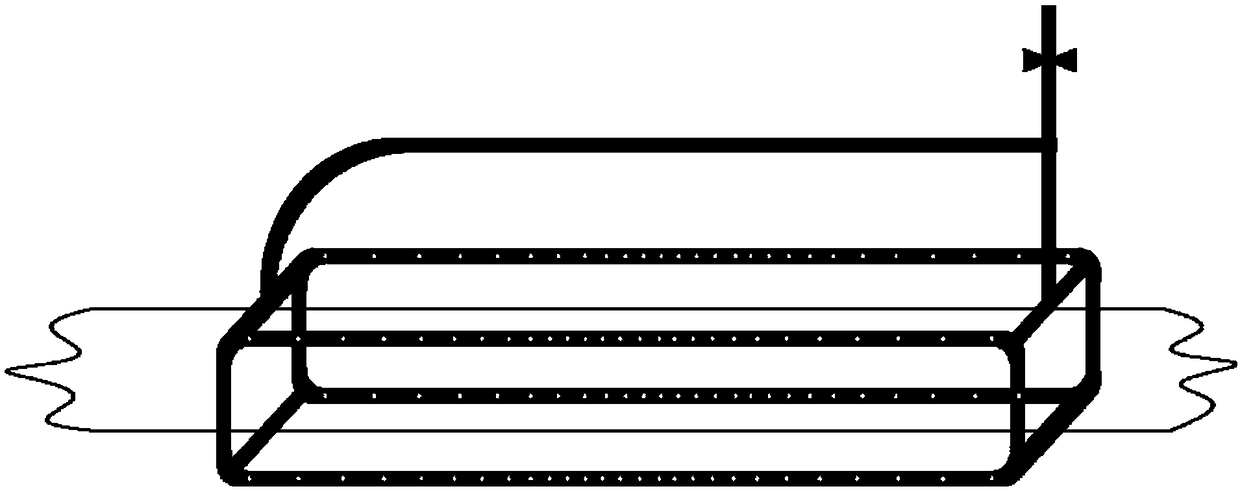

[0021] Embodiment: adopt intermediate frequency (MF) magnetron reactive sputtering, use magnesium target as metal sputtering target, in the coated with IBAD-MgO / SDP-Y 2 o 3 On the 500mm long and 10mm wide Hastelloy flexible substrate, a layer of MgO thin film was homogeneously epitaxy on both sides by intermediate frequency magnetron sputtering.

[0022] Step 1. Prepare and process the baseband. IBAD-MgO / SDP-Y with 10nm deposited on both sides 2 o 3 The Hastelloy flexible base tape is loaded into the first winding reel 1, and the other end of the base tape is introduced into the second winding reel 2; so that both sides of the Hastelloy flexible base tape are in good contact with the silver-tungsten alloy rods of the self-heating electrode units 10 and 11 , and the Hastelloy flexible base belt 5 moves at a constant speed under the control of the motor.

[0023] Step 2. Place the metal magnesium targets with a length of 80 mm, a width of 40 mm, and a thickness of 5 mm respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com