Post weld heat treatment method for flash welding joints of U71MnH rails

A technology for post-weld heat treatment and welded joints is applied in the field of rail welding, which can solve the problems of low hardness of welded joints, and achieve the effects of improving performance status, good promotion and application prospects, and normal structure and morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The welding seam area of the 60kg / m U71MnH rail welded joint was heated to 940°C by intermediate frequency heating method, and the heating time was 145s. After the heating is stopped, when the temperature of the rail joint tread drops to 810°C, carry out air spray cooling. The air spray port is 30mm away from the rail joint surface, and the spray air pressure is 0.15±0.05MPa. When the joint tread temperature drops to the final cooling temperature of At 435°C, the blast cooling was stopped, and then the rail joints were naturally cooled to room temperature. Referring to the requirements of the TB / T 1632.2-2014 standard, the HR-150A Rockwell hardness tester is used to test the Rockwell hardness of 5 mm below the tread of the rail head on the longitudinal section. In this embodiment, the ratio of the average hardness HJ of the post-weld heat treatment joint of 60kg / m U71MnH rail to the average hardness HP of the base metal is 0.98, and the ratio of the average hardness H...

Embodiment 2

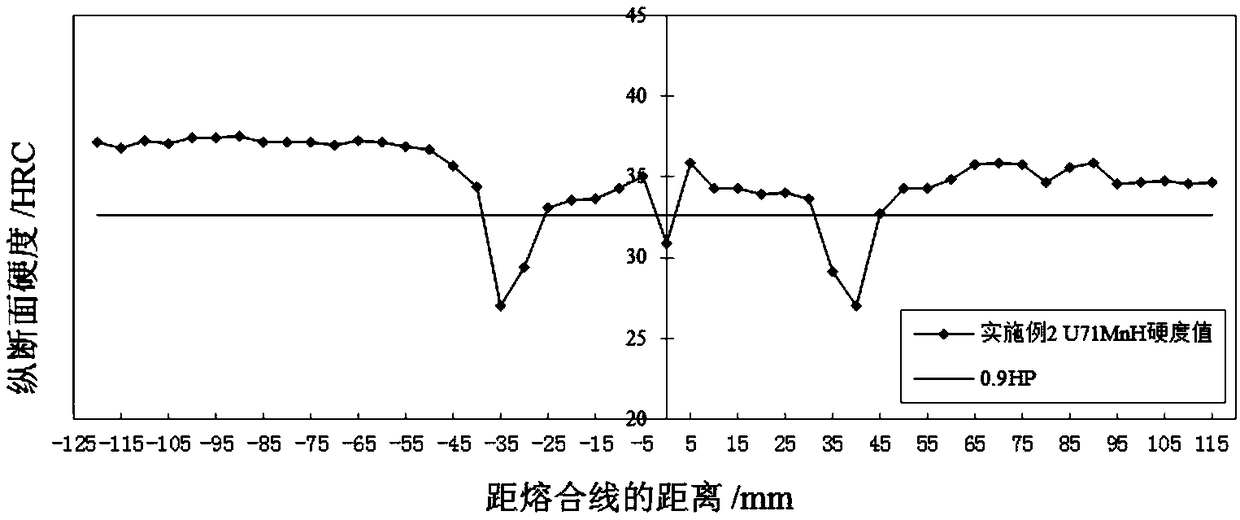

[0033] The welding seam area of the 60kg / m U71MnH rail welded joint was heated to 919°C by intermediate frequency heating, and the heating time was 138s. After the heating is stopped, when the temperature of the rail joint tread drops to 785°C, carry out air spray cooling. The air spray port is 30mm away from the rail joint surface, and the spray air pressure is 0.15±0.05MPa. When the joint tread temperature drops to the final cooling temperature of At 410°C, the blast cooling was stopped, and then the rail joints were naturally cooled to room temperature. Referring to the requirements of the TB / T 1632.2-2014 standard, the HR-150A Rockwell hardness tester is used to test the Rockwell hardness of 5 mm below the tread of the rail head on the longitudinal section. In this embodiment, the ratio of the average hardness HJ of the post-weld heat treatment joint of 60kg / m U71MnH rail to the average hardness HP of the base metal is 0.95, and the ratio of the average hardness HJ1 of t...

Embodiment 3

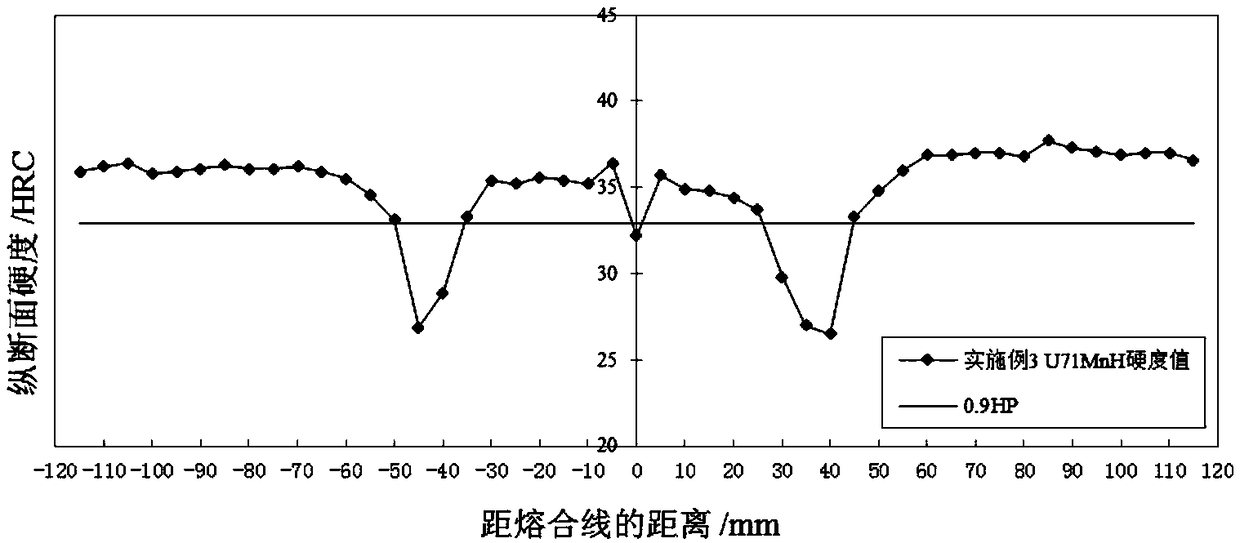

[0035] The welding seam area of the 60kg / m U71MnH rail welded joint was heated to 921°C by intermediate frequency heating method, and the heating time was 136s. After the heating is stopped, when the temperature of the rail joint tread drops to 800°C, carry out jet cooling. The air jet is 30mm away from the rail joint surface, and the jet pressure is 0.15±0.05MPa. When the joint tread temperature drops to the final cooling temperature of At 435°C, the blast cooling was stopped, and then the rail joints were naturally cooled to room temperature. Referring to the requirements of the TB / T 1632.2-2014 standard, the HR-150A Rockwell hardness tester is used to test the Rockwell hardness of 5 mm below the tread of the rail head on the longitudinal section. In this embodiment, the ratio of the average hardness HJ of the post-weld heat treatment joint of 60kg / m U71MnH rail to the average hardness HP of the base metal is 0.91, and the ratio of the average hardness HJ1 of the soft spot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com