A rapid preparation method of high-temperature-resistant structural wave-absorbing ceramic matrix composites

A composite material and wave-absorbing technology, which is applied in the field of ceramic matrix composite material preparation, can solve the problems of long cycle, high cost, and urgent improvement of material performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

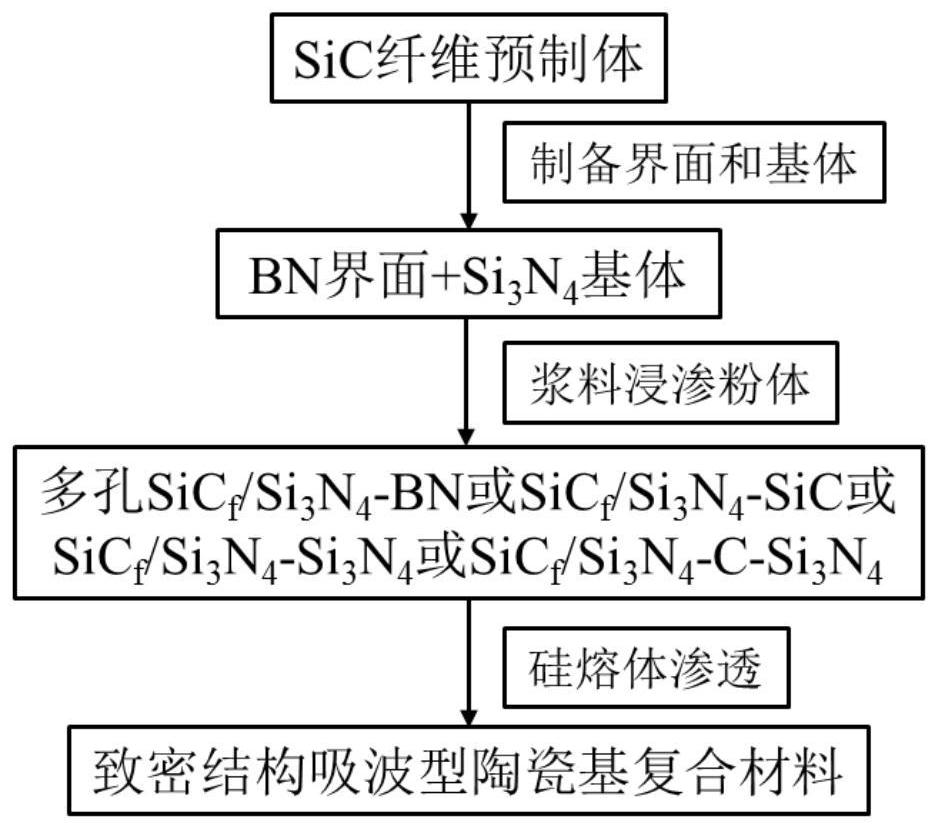

[0030] The technical solution used by the present invention to solve its technical problems: a rapid preparation method of a high-temperature-resistant structural wave-absorbing ceramic matrix composite material, which is characterized in that it includes the following steps:

[0031] (a) Preparation of uniform and dense thin BN interface and Si in the interior / surface of the pretreated fiber preform 3 N 4 matrix, to obtain SiC in a loose state with a large porosity f / Si 3 N 4 Composite material, Si 3 N 4 The matrix effectively fills the pores in the fiber bundles and partially fills the gaps between the fiber bundles, which can effectively protect the fibers from damage. Ultrasonic cleaning and drying of the prefabricated body with a certain density and open porosity;

[0032] (b) Add sodium carboxymethylcellulose and BN powder (BN is hexagonal BN, cubic BN or rhombohedral BN), Si 3 N 4 Powder (Si 3 N 4 α-Si 3 N 4 or β-Si 3 N 4 ), SiC powder (SiC is α-SiC or β-...

Embodiment 1

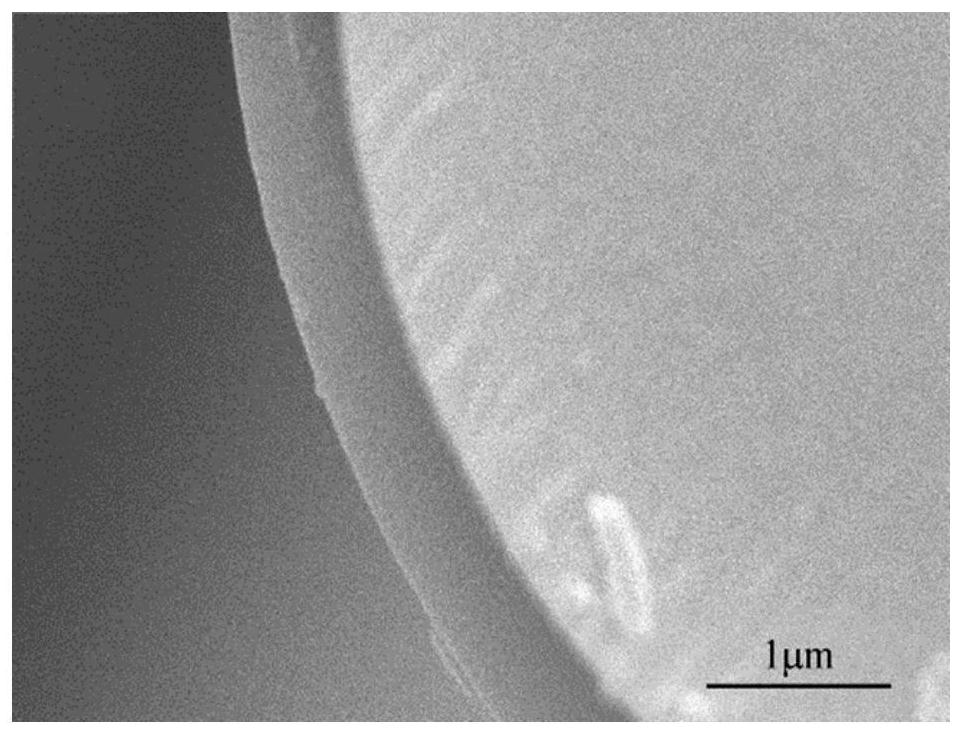

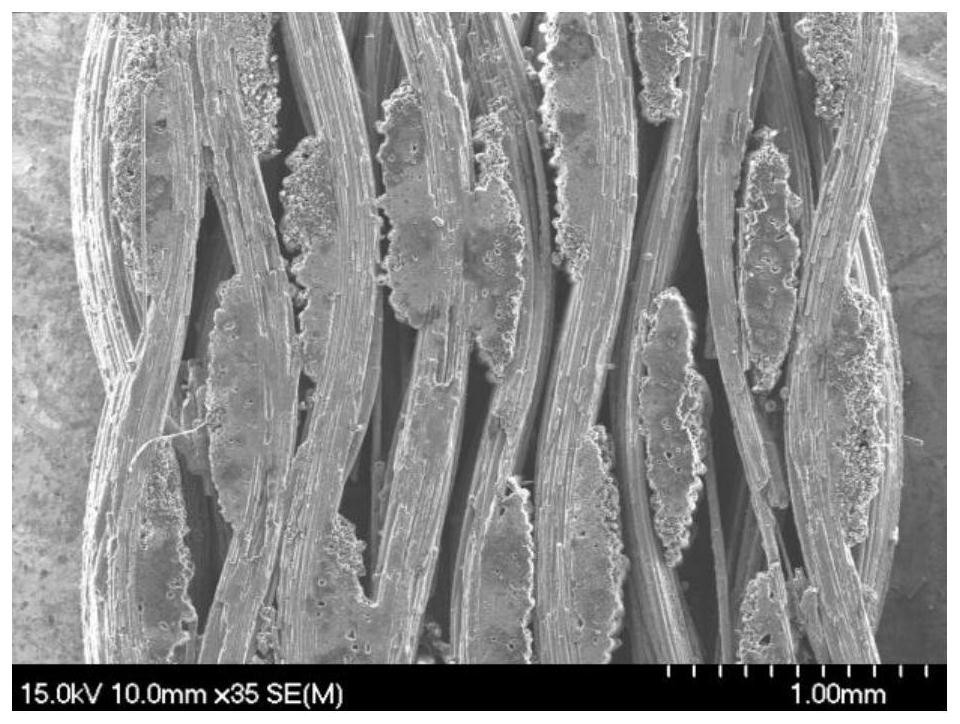

[0036] Example 1: Prepare a uniform and dense BN interface (about 480nm) inside / surface of the pretreated two-dimensional porous SiC fiber preform, such as figure 2 As shown, the preparation of dense Si in the preform with BN interface 3 N 4 matrix, to obtain a two-dimensional porous SiC in a loose state with a large porosity f / Si 3 N 4 Composite preform with a density of 1.6 g / cm 3 , with a porosity of 42vol.%, after ultrasonic cleaning and drying, for use, such as image 3 shown. Add 1g of sodium carboxymethyl cellulose and 100g of hexagonal BN powder with a particle size of 1μm to 200g of distilled water, stir evenly, put it into a ball mill tank, add 600g of corundum balls with a particle size of 5-12mm in total weight and ball mill for 10 hours to make a slurry material. Slurry impregnation adopts the method of vacuum impregnation combined with pressure impregnation. The open container containing the slurry and the two-dimensional SiC f / Si 3 N 4 Put the comp...

Embodiment 2

[0037] Example 2: Prepare a uniform and dense BN interface (about 380nm) inside / surface of the pretreated three-dimensional porous SiC fiber preform, and prepare a dense Si in the preform with a BN interface. 3 N 4 The matrix obtains a three-dimensional porous SiC in a loose state with a large porosity f / Si 3 N 4 Composite preform with a density of 1.7 g / cm 3 , the porosity is about 43vol.%, and it is used after ultrasonic cleaning and drying. Add 1.5 g of sodium carboxymethylcellulose and 150 g of β-SiC powder with a particle size of 2 μm in 300 g of distilled water, stir well, pour into a ball mill jar, add 900 g of corundum balls with a particle size of 5 to 12 mm in total weight, and mill for 15 hours. into slurry. Slurry impregnation adopts the method of vacuum impregnation combined with pressure impregnation. The open container containing the slurry and the 3D SiC f / Si 3 N 4 Put the composite material prefabricated body into the same airtight container, vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com