Method for reducing adverse effect of nano-zinc oxide on anaerobic biological treatment of sewage

A technology of nano-zinc oxide and anaerobic organisms, applied in the field of reducing the toxicity of ZnONPs to anaerobic biological treatment of sewage, can solve the problems of reducing the toxicity of ZnONPs, changing the characteristics of nanomaterials, affecting the scope and effect of use, and reducing adverse effects and strengthening Resilience, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1(

[0020] Embodiment 1 (comparative example): a kind of method that is used to reduce the adverse effect of nano-zinc oxide on sewage anaerobic biological treatment, it is to carry out according to the following steps: first will be taken from the particle sewage in the reactor of processing citric acid waste water Sludge was domesticated in laboratory upflow anaerobic sludge bed (UASB, effective volume 4L), and the domestication nutrient solution was composed of carbon sources (glucose, alcohol, sodium acetate, sodium propionate and sodium butyrate, various carbon sources COD equal concentration), nitrogen source (NH 4 Cl), phosphorus source (KH 2 PO 4 and K 2 HPO 4 ) and water, the nutrient solution C:N:P=100:5:1, the initial pH is 6.8-7.6. The other main trace elements N, P, Ca, Mg, Fe come from NH 4 Cl, KH 2 PO 4 , CaCl 2 , MgCl 2 ·6H 2 O, FeCl 3 , the concentration is 1000, 500, 200, 200, 50 mg / L. Acclimatization process: The initial COD of acclimatization nutrie...

Embodiment 2(

[0023] Embodiment 2 (comparative example): a kind of method that is used to reduce the adverse effect of nano-zinc oxide on sewage anaerobic biological treatment is carried out as follows: first according to the domestication mode of embodiment 1, the inoculum slime that domestication is good is added to reaction In the container (serum bottle), the TS concentration was 1500 mg / L, and then the fermentation nutrient solution and ZnO NPs dispersion were added to the serum bottle, and the effective volume of the mixed phase was 400 mL. The fermentation nutrient solution is composed of carbon source (glucose and sodium acetate, COD ratio is 1:1), nitrogen source (NH 4 Cl), phosphorus source (KH 2 PO 4 and K 2 HPO 4 ) and water, the fermentation nutrient solution C:N:P=100:5:1, the initial pH is 7.0±0.2, the COD is 3000 mg / L; the particle size of ZnO NPs is controlled to be 50-100 nm, and the exposure of ZnO NPs The concentration is 30 mg / g-TS. After removing the oxygen in the...

Embodiment 3

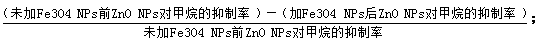

[0025] Embodiment 3: a kind of method that is used to reduce the adverse effect of nano-zinc oxide on the anaerobic biological treatment of sewage, it is carried out as follows: first according to the domestication mode of embodiment 1, the inoculum slime that domestication is good is added to reactor ( serum bottle), the TS concentration was 1500 mg / L, then the fermentation nutrient solution and ZnO NPs dispersion were added to the serum bottle, and finally Fe 3 o 4 NPs dispersion, the effective volume of the obtained mixed phase is 400 mL. The fermentation nutrient solution is composed of carbon source (glucose and sodium acetate, COD ratio is 1:1), nitrogen source (NH 4 Cl), phosphorus source (KH 2 PO 4 and K 2 HPO 4 ) and water, the fermentation nutrient solution C:N:P=100:5:1, the initial pH is 7.0±0.2, the COD is 3000 mg / L; the particle size of ZnO NPs is controlled to be 50-100 nm, and the exposure of ZnO NPs The concentration is 30 mg / g-TS; control Fe 3 o 4 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com