Lignin-based transition metal/nitrogen doped carbon material, and preparation and application thereof

A transition metal and nitrogen-doped carbon technology, which is applied in the fields of materials science and energy storage and conversion, can solve the problems of agglomerating inactive metal particles and affecting oxygen reduction performance, and achieve simple preparation process, high-value utilization, and step-by-step little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Dissolve ferric chloride in water to obtain an aqueous ferric chloride solution with a concentration of 0.1g / mL; then add lignosulfonic acid (the mass ratio of lignosulfonic acid and ferric chloride is 1:2) into chlorine Stir evenly in the iron solution aqueous solution to obtain a lignosulfonic acid / iron chloride mixture;

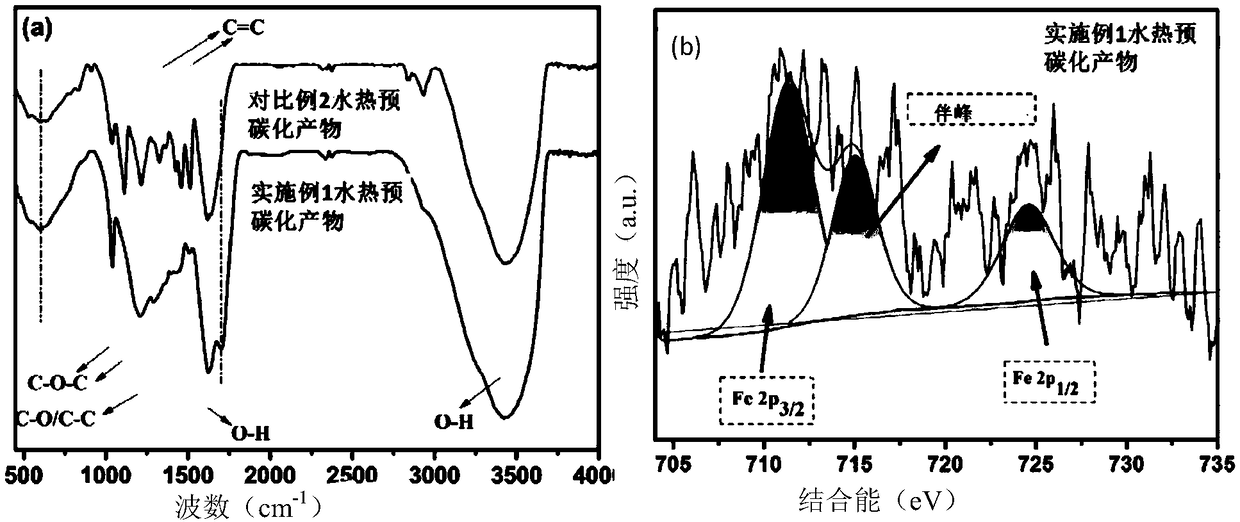

[0044] (2) Transfer the ligninsulfonic acid / ferric chloride mixture of step (1) to a hot water reactor, heat up to 180°C for 4 hours of hydrothermal treatment, cool to room temperature after the reaction, and wash the solid product with water and dry (60°C) to obtain hydrothermal pre-carbonization products;

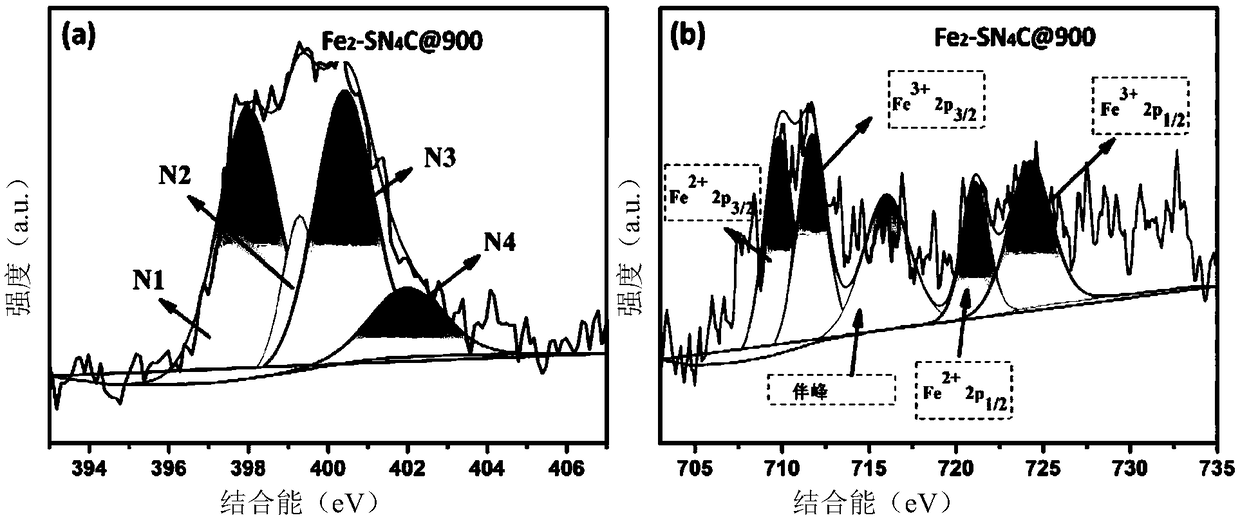

[0045] (3) Fully mix the pre-carbonized product and melamine according to the mass ratio of 1:4, place in a tube furnace, heat up to 900°C in an inert atmosphere (nitrogen) for carbonization for 2 hours, and cool to room temperature after the reaction is complete. The carbonized product was washed with 1M hydrochloric acid solution, then washed...

Embodiment 2

[0048] (1) Dissolve ferric chloride in water to obtain an aqueous ferric chloride solution with a concentration of 0.1g / mL; then add lignosulfonic acid (the mass ratio of lignosulfonic acid and ferric chloride is 1:2) into chlorine Stir evenly in the iron solution aqueous solution to obtain a lignosulfonic acid / iron chloride mixture;

[0049] (2) Transfer the lignin sulfonic acid / ferric chloride mixture of step (1) to the reaction kettle, place it in a muffle furnace, heat up to 180°C for 4 hours of hydrothermal treatment, and cool to room temperature after the reaction is over. Wash with water and dry at 60°C to obtain hydrothermal pre-carbonized products;

[0050] (3) Mix the pre-carbonized product and melamine thoroughly at a mass ratio of 1:4, place in a tube furnace, heat up to 800°C in an inert atmosphere (nitrogen) for carbonization for 2 hours, and cool to room temperature after the reaction is complete. The carbonized product was washed with 1M hydrochloric acid solution,...

Embodiment 3

[0053] (1) Dissolve ferric chloride in water to obtain an aqueous ferric chloride solution with a concentration of 0.1g / mL; then add lignosulfonic acid (the mass ratio of lignosulfonic acid and ferric chloride is 1:2) into chlorine Stir evenly in the iron solution aqueous solution to obtain a lignosulfonic acid / iron chloride mixture;

[0054] (2) Transfer the lignin sulfonic acid / ferric chloride mixture of step (1) to a reactor of a certain capacity, place it in a muffle furnace, heat it up to 180°C for 4 hours of hydrothermal treatment, and cool to room temperature after the reaction is complete. The solid product is washed with water and dried at 60°C to obtain a hydrothermal pre-carbonized product;

[0055] (3) Mix the pre-carbonized product and melamine thoroughly at a mass ratio of 1:4, place in a tube furnace, heat up to 1000°C in an inert atmosphere (nitrogen) for carbonization for 2 hours, and cool to room temperature after the reaction is complete. The carbonized product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com