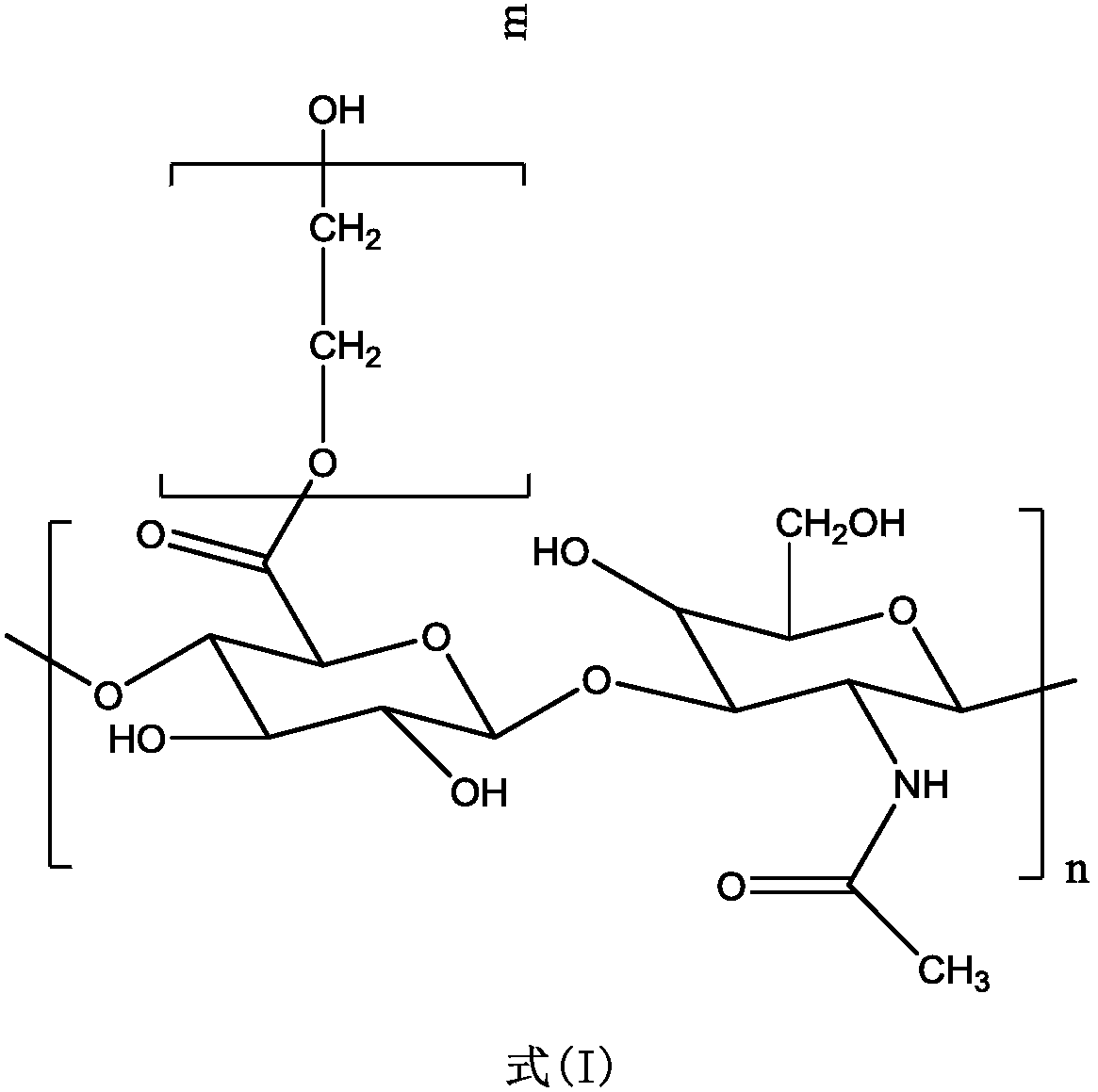

Modified hyaluronic acid injectable filling material and preparation method thereof

A filling material, hyaluronic acid technology, applied in pharmaceutical formulations, pharmaceutical sciences, prostheses, etc., can solve the problems of non-disclosure, and achieve the effects of good stability, good biocompatibility, and stable metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

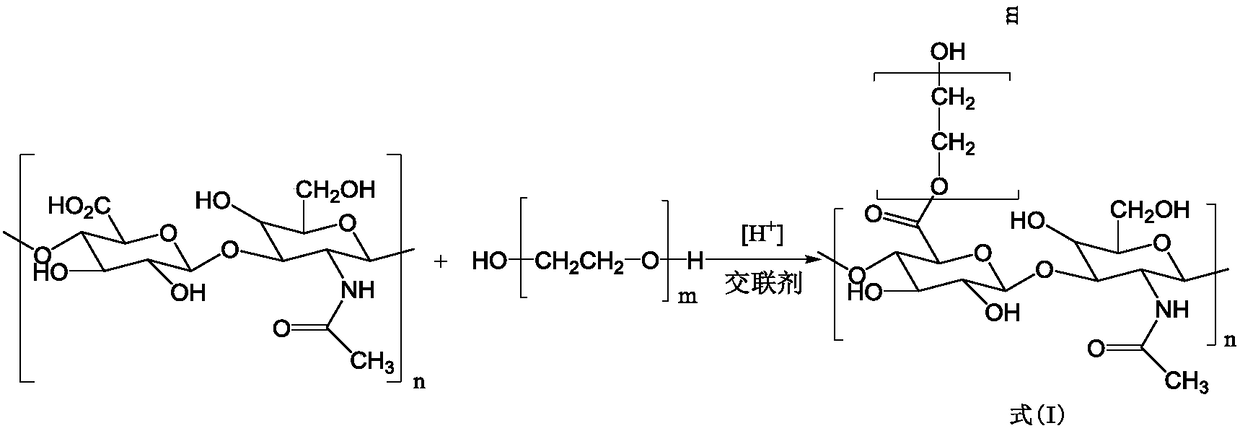

Method used

Image

Examples

Embodiment 1

[0039] Step (1) Preparation of cross-linked hyaluronic acid gel:

[0040] a. Weigh hyaluronic acid / polyethylene glycol / HOBc / EDC (hyaluronic acid / polyethylene glycol / HOBt / EDC=1g / 0.5g / 0.1 / 0.1,w / w) according to a certain ratio, and dissolve them in 50mL deionized Stir well in water to make it evenly mixed;

[0041] b. Add NaH to the reaction system 2 PO 4 -NaHPO 4 , control the pH value of the reaction system=5,;

[0042] c. Control the reaction temperature to 60-80°C and stir thoroughly for 12 hours;

[0043] d. Dialyzing the reaction product to obtain a cross-linked hyaluronic acid gel.

[0044] Step (2): Weigh free transparent hyaluronic acid gel aqueous solution (molecular weight: 50KDa) according to the proportion (free transparent hyaluronic acid gel: cross-linked hyaluronic acid gel = 0.8g / 1g, w / w), and add to the solution prepared in step (1). Preparation of the prepared cross-linked hyaluronic acid gel, and fully mixing and stirring at room temperature;

[0045] S...

Embodiment 2

[0048] Step (1) Preparation of cross-linked hyaluronic acid gel:

[0049] a. Weigh hyaluronic acid / polyethylene glycol / HOBc / EDC (hyaluronic acid / polyethylene glycol / HOBt / EDC=1g / 1g / 0.1 / 0.1,w / w) according to a certain ratio, and dissolve them in 50mL deionized water Stir well to make it evenly mixed;

[0050] b. Add NaH to the reaction system 2 PO4 -NaHPO 4 , control the pH value of the reaction system=5,;

[0051] c. Control the reaction temperature to 60-80°C and stir thoroughly for 12 hours;

[0052] d. Dialyzing the reaction product to obtain a cross-linked hyaluronic acid gel.

[0053] Step (2): Weigh the free transparent hyaluronic acid gel aqueous solution (molecular weight is 50KDa) according to the proportion (free transparent hyaluronic acid gel: cross-linked hyaluronic acid gel = 0.5g / 1g, w / w), add to step (1) Preparation of the prepared cross-linked hyaluronic acid gel, and fully mixing and stirring at room temperature;

[0054] Step (3): Weigh water-soluble vi...

Embodiment 3

[0057] Step (1) Preparation of cross-linked hyaluronic acid gel:

[0058] a. Weigh hyaluronic acid / polyethylene glycol / HOBc / EDC (hyaluronic acid / polyethylene glycol / HOBt / EDC=0.5g / 1 / 0.1 / 0.1,w / w) according to a certain ratio, and dissolve them in 50mL deionized Stir well in water to make it evenly mixed; b. Add NaH to the reaction system 2 PO 4 -NaHPO 4 , control the pH value of the reaction system=5;

[0059] c. Control the reaction temperature to 60-80°C and stir thoroughly for 12 hours;

[0060] d. Dialyzing the reaction product to obtain a cross-linked hyaluronic acid gel.

[0061] Step (2): Weigh the free transparent hyaluronic acid gel aqueous solution (molecular weight is 50KDa) according to the proportion (free transparent hyaluronic acid gel: cross-linked hyaluronic acid gel = 0.5g / 1g, w / w), add to step (1) Preparation of the prepared cross-linked hyaluronic acid gel, and fully mixing and stirring at room temperature;

[0062] Step (3): Weigh water-soluble vitamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com