Amisulpride tablet and preparation method thereof

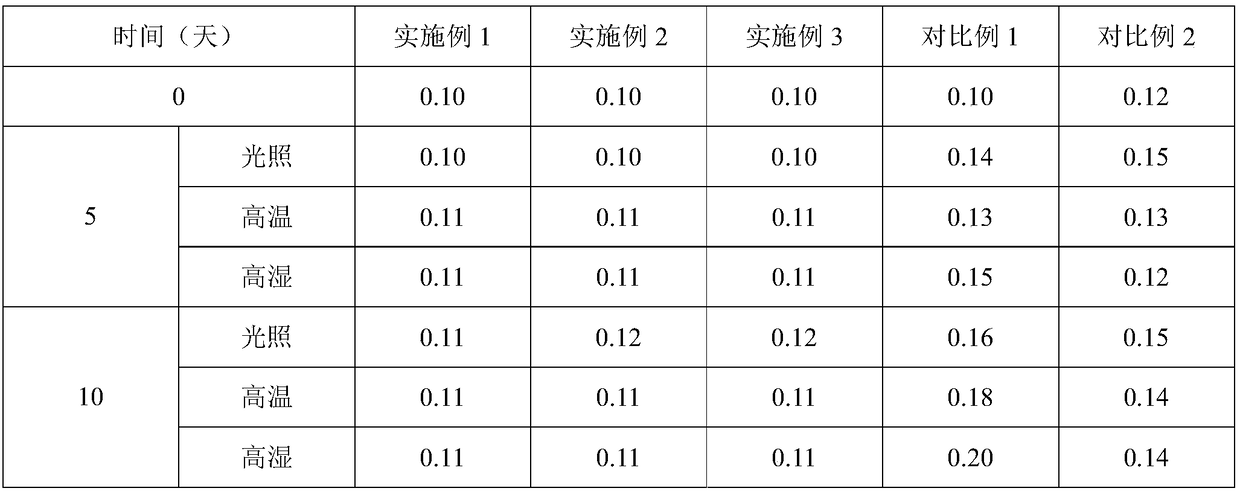

A technology of amisulpride tablets and amisulpride, which is applied in the direction of pharmaceutical formula, medical preparations of non-active ingredients, pill delivery, etc. It can solve the instability of amisulpride tablets and the long disintegration time limit of tablets , unfavorable transportation and storage issues, to achieve the effect of rapid dissolution, avoiding the incidence of adverse reactions, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The amisulpride tablet comprises the following components and their weight percentages: 60% of amisulpride, 8% of lactose, 20% of microcrystalline cellulose, 5% of sodium carboxymethyl starch, and 2.7% of hypromellose , magnesium stearate 0.1%, additive 1%, methoxy polyethylene glycol acrylate 1%, magnesium chloride 0.2%, coating powder 2%; Said additive comprises the following components and their weight percentages: A 15% spartame, 45% essence, 40% sodium chloride.

[0030] The preparation method of the amisulpride tablet is as follows: 1) taking raw materials in proportion, mixing amisulpride, lactose, microcrystalline cellulose, sodium carboxymethyl starch and additives to obtain a mixture;

[0031] 2) Add hypromellose aqueous solution and methoxypolyethylene glycol acrylate with a mass percentage concentration of 5-6% to the mixture, mix well and then wet granulate in a boiling granulator, the granulation parameters For: the air inlet temperature is 110°C to ensur...

Embodiment 2

[0034] The amisulpride tablet comprises the following components and their weight percentages: 63% of amisulpride, 8% of lactose, 15% of microcrystalline cellulose, 4% of sodium carboxymethyl starch, and 2% of hypromellose , magnesium stearate 0.3%, additive 0.8%, methoxy polyethylene glycol acrylate 2.5%, magnesium chloride 0.4%, coating powder 3%; Said additive comprises the following components and weight percentages thereof: A 10% spartame, 40% essence, 50% sodium chloride.

[0035] The preparation method of the amisulpride tablet is as follows: 1) taking raw materials in proportion, mixing amisulpride, lactose, microcrystalline cellulose, sodium carboxymethyl starch and additives to obtain a mixture;

[0036] 2) Add hypromellose aqueous solution and methoxypolyethylene glycol acrylate with a mass percentage concentration of 5-6% to the mixture, mix well and wet granulate in a boiling granulator, the granulation parameters For: the air inlet temperature is 110°C to ensure...

Embodiment 3

[0039] The amisulpride tablet includes the following components and their weight percentages: 70% amisulpride, 4% lactose, 15.5% microcrystalline cellulose, 3% sodium carboxymethyl starch, and 1% hypromellose , magnesium stearate 0.5%, additive 0.5%, methoxy polyethylene glycol acrylate 3%, magnesium chloride 0.5%, coating powder 2%; Said additive comprises the following components and their weight percentages: A 10% spartame, 40% essence, 50% sodium chloride.

[0040] The preparation method of the amisulpride tablet is as follows: 1) taking raw materials in proportion, mixing amisulpride, lactose, microcrystalline cellulose, sodium carboxymethyl starch and additives to obtain a mixture;

[0041] 2) Add hypromellose aqueous solution and methoxypolyethylene glycol acrylate with a mass percentage concentration of 5-6% to the mixture, mix well and wet granulate in a boiling granulator, the granulation parameters For: the air inlet temperature is 110°C to ensure complete fluidiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com