Heat dissipation device for double-clad fiber grating of high-power fiber laser

A double-clad fiber and fiber laser technology, which is applied to laser cooling devices, lasers, and laser components, can solve problems such as fiber gratings are easy to break, have a large expansion coefficient, and affect the service life of devices. It is easy to mass produce, The effect of simple package structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

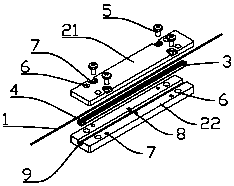

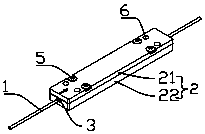

[0042] see figure 1 , figure 2 . A heat dissipation device for double-clad fiber gratings for high-power fiber lasers, comprising an aluminum alloy shell 2 and an inner core 3 of silicon-aluminum alloy, and the shell 2 is pasted up and down by a shell cover 21 and a shell bottom 22 Combined into one body, the inner core 3 is arranged between the case cover 21 and the case bottom 22 . The shell cover 21 and the shell bottom 22 are planar plate-shaped structures, and both sides of the shell cover 21 and the shell bottom 22 are provided with threaded holes 6, and the shell cover 21 and the shell bottom 22 are fastened by being arranged in the threaded holes 6. The screw 5 fixes the inner core 3 between the shell cover 21 and the shell bottom 22, the grating section of the double-clad fiber grating 1 is nested in the inner core 3, and the optical fibers at both ends of the double-clad fiber grating grating section extend out of the shell 2 external.

[0043] see image 3 . ...

Embodiment 2

[0048] see Figure 5 , Image 6. A heat dissipation device for double-clad fiber gratings for high-power fiber lasers, comprising a copper alloy shell 2 and a silicon-aluminum alloy inner core 3, the shell 2 is composed of a shell bottom 22 and a shell cover 21, the The inner core 3 described above is arranged between the shell bottom 22 and the shell cover 21, and the lower surface of the shell cover 21 and the upper surface of the shell bottom 22 are glued together to fix the inner core 3 between the shell bottom 22 and the shell cover 21, The grating segment of the double-clad fiber grating 1 is embedded in the inner core 3 , and the optical fibers at both ends of the grating segment of the double-clad fiber grating extend out of the housing 2 .

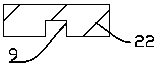

[0049] Such as Figure 7 shown. The upper surface of the shell bottom 22 is horizontally provided with a core groove 9 that runs through the two ends of the shell bottom 22 and has a U-shaped cross-section. The length of the c...

Embodiment 3

[0054] see Figure 9 , Figure 10 and Figure 11 . A heat dissipation device for a double-clad fiber grating used in a high-power fiber laser, comprising an aluminum alloy shell 2 and an inner core 3 of silicon-aluminum alloy. The housing 2 is a plate-shaped structure, and the housing 2 is provided with a circular through hole 14 passing through both ends of the housing 2, and the middle part of the housing 2 is provided with a slot 13 communicating with the circular through hole 14. The inner core 3 is embedded in the circular through hole 14 of the shell 2, and the slot 13 on the shell 2 is filled with 353ND glue to fix the inner core 3 and the shell 2 as a whole, so as to prevent the inner core from expanding with heat and contracting with cold. The core 3 moves out of the circular through hole 14 of the housing 2 .

[0055] In order to facilitate the fixing of the double-clad fiber grating heat sink and the heat sink, the housing 2 on both sides of the circular through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com