Preparation method and application of amphiphilic thermo-responsive block copolymer

A temperature-sensitive block and polymer technology, applied in the field of polymers, can solve the problems of few types of temperature-sensitive polymers, rare research, high low critical phase transition temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

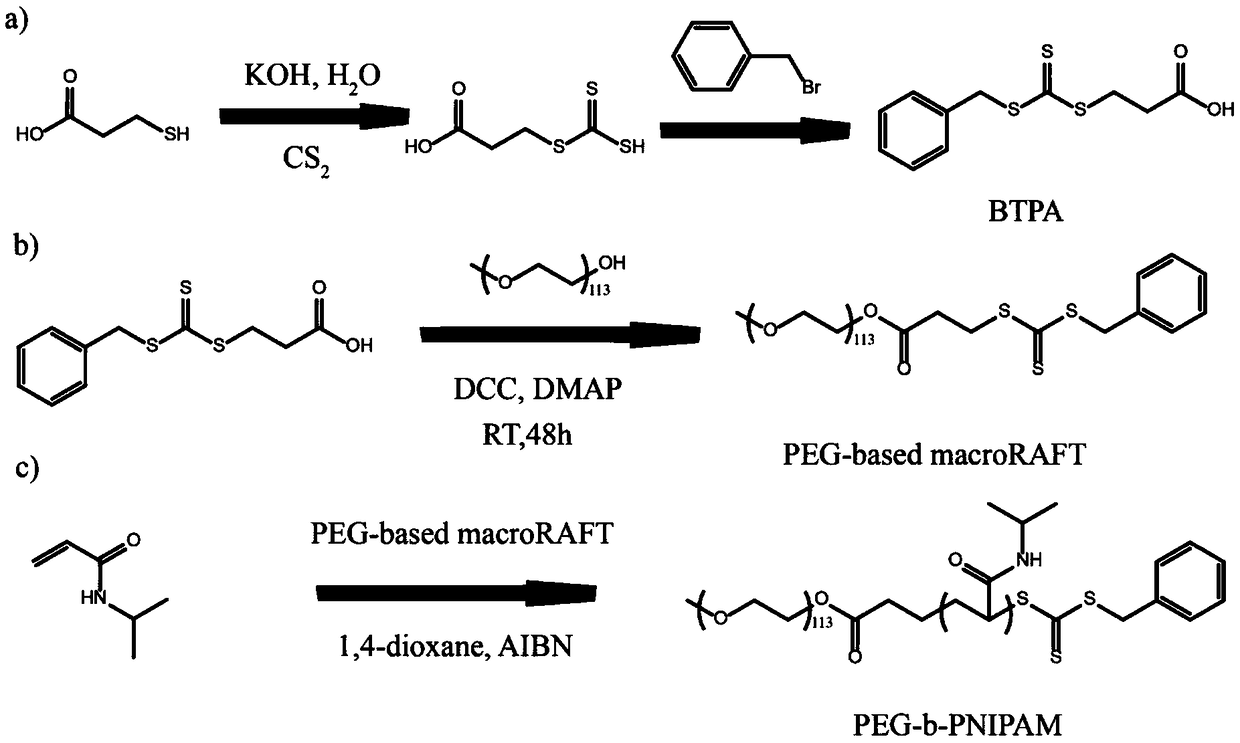

[0034] Step (1): Preparation of RAFT reagent (BTPA)

[0035] In aqueous potassium hydroxide solution (104mg / mL, 31.25mL), add 3-mercaptopropionic acid (2.5mL, 28.75mmol) dropwise, then add carbon disulfide (3.75mL, 28.75mmol) dropwise, and place at room temperature Reaction 5h. Benzyl bromide (4.95g, 28.75mmol) was added, and the reaction was refluxed at 85°C for 12h. After the reaction, the mixture was cooled to room temperature, chloroform (70.0 mL) was added, and excess hydrochloric acid was added to adjust the pH value, and the organic layer was repeatedly washed with a large amount of distilled water, and the organic layer was rotary evaporated to obtain a yellow solid.

[0036] Step (2): Preparation of Macromolecular Chain Transfer Agent Based on Polyethylene Glycol Monomethyl Ether

[0037] Dry polyethylene glycol monomethyl ether (15.0 g, 3.0 mmol) was dissolved in 30.0 mL of anhydrous toluene, and a large amount of solvent was removed by azeotropic distillation at 5...

Embodiment 2

[0041] Step (1) and step (2) are with embodiment 1;

[0042] Step (3): Preparation of thermosensitive block polymer PEG-b-PNIPAM

[0043] Polyethylene glycol monomethyl ether macromolecular chain transfer agent (0.315g, 0.06mmol), N-isopropylacrylamide (NIPAM, 0.6675g, 6mmol) and azobisisobutyronitrile (AIBN, 4mg, 24μmol ) was dissolved in 1,4-dioxane (3.0 mL) and added to a one-necked flask. The mixture was sealed under vacuum after three freeze-pump-thaw cycles. React in an oil bath at 80°C for 12 hours, quench the polymerization with liquid nitrogen, unseal the tube, dilute with 1,4-dioxane, and precipitate the mixture with excess ether. The above dissolution-precipitation cycle was repeated three times to obtain a light yellow thermosensitive block polymer PEG-b-PNIPAM.

Embodiment 3

[0045] Step (1) and step (2) are with embodiment 1;

[0046] Step (3): Preparation of thermosensitive block polymer PEG-b-PNIPAM

[0047] Polyethylene glycol monomethyl ether macromolecular chain transfer agent (0.21g, 0.04mmol), N-isopropylacrylamide (NIPAM, 0.445g, 4mmol) and azobisisobutyronitrile (AIBN, 3mg, 18μmol ) was dissolved in 1,4-dioxane (2.0 mL) and added to a one-necked flask. The mixture was sealed under vacuum after three freeze-pump-thaw cycles. React in an oil bath at 75°C for 22 hours, quench the polymerization with liquid nitrogen, unseal the tube, dilute with 1,4-dioxane, and precipitate the mixture with excess ether. The above dissolution-precipitation cycle was repeated three times to obtain a light yellow thermosensitive block polymer PEG-b-PNIPAM.

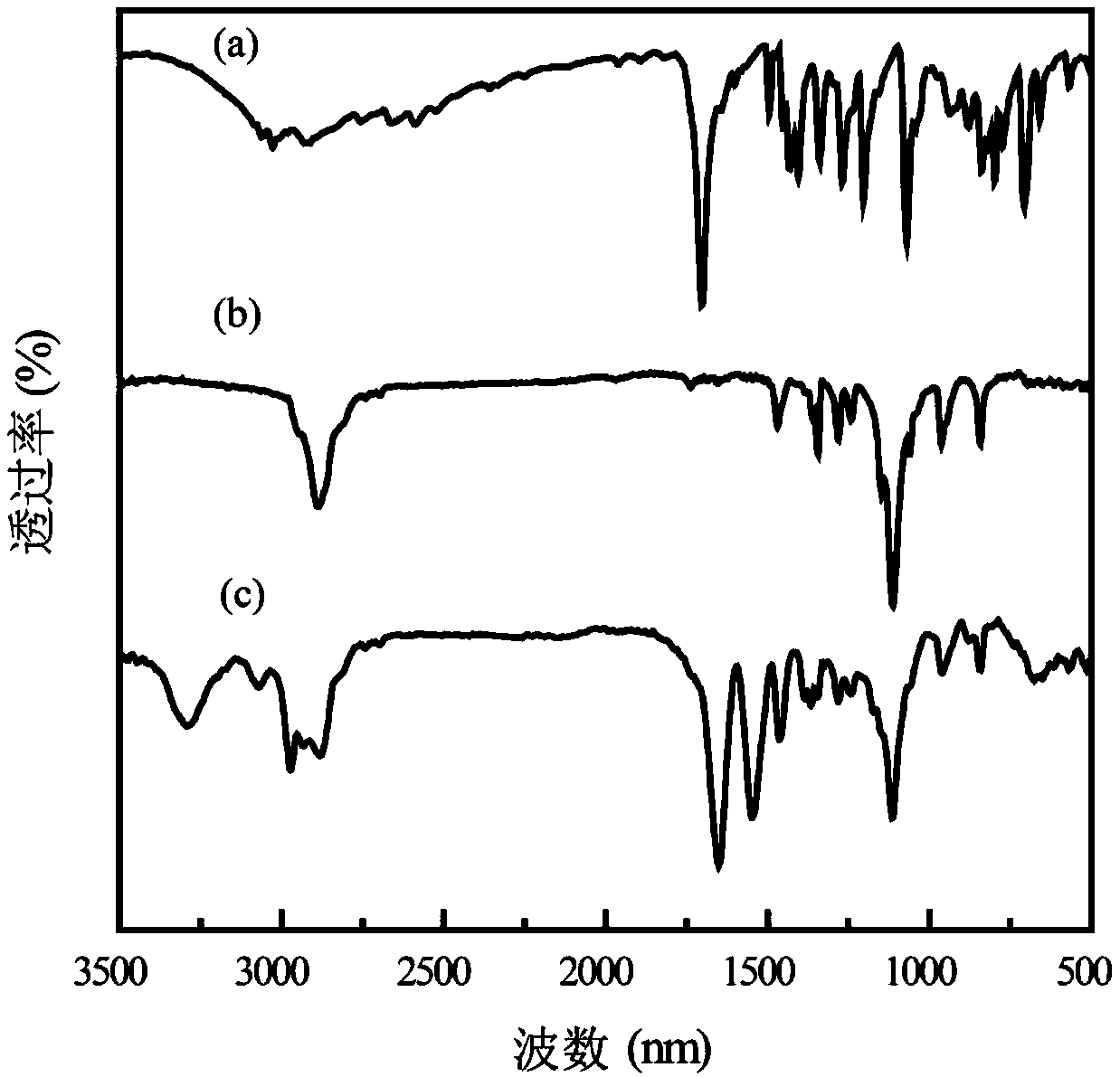

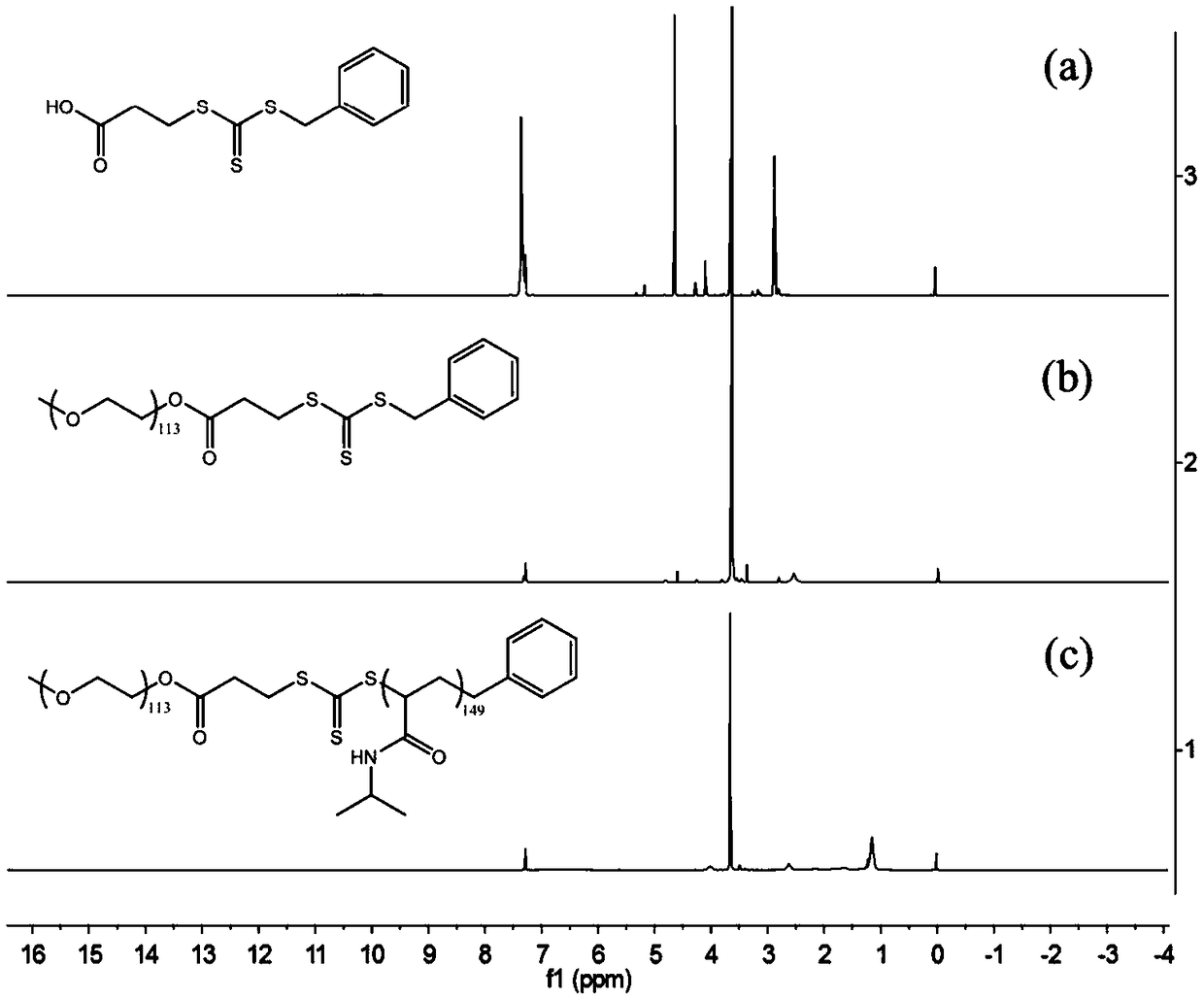

[0048] Such as figure 1 Shown is the synthetic process schematic diagram (a) of the RAFT reagent (BTPA) prepared in embodiment 1, the synthetic process schematic diagram (b) of the macromolecular chain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com