Steel plate for high-performance and corrosion-resisting movable pressure container and manufacturing method thereof

A technology of moving pressure and manufacturing method, applied in the field of alloy steel manufacturing, can solve the problems of unspecified steel microstructure, unmentioned corrosion resistance, unmentioned impact performance and corrosion resistance, etc., and achieve excellent corrosion resistance , excellent low temperature toughness and welding performance, the effect of low welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example is a high-performance corrosion-resistant mobile pressure vessel with a steel plate thickness of 10mm, and its chemical composition and mass percentage are as follows: C: 0.125%, Si: 0.45%, Mn: 1.55%, P: 0.012%, S: 0.003%, Ni: 0.25%, V: 0.035%, Nb: 0.045%, Ti: 0.012%, N: 0.01%, and the rest is Fe and inevitable inclusions.

[0047] The mechanical properties of the steel plate described in this example: the yield strength is 451MPa, the tensile strength is 620MPa, the elongation is 29%, and the KV2 of the steel plate at -50°C transverse direction reaches 176J.

[0048] The metallographic structure of the steel plate described in this embodiment is mainly ferrite and pearlite.

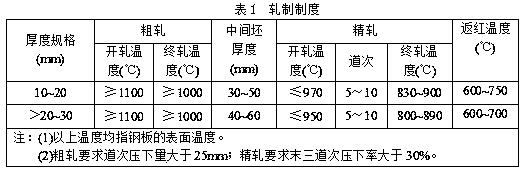

[0049] The manufacturing method of the steel plate described in this embodiment includes the following steps: desulfurization treatment of molten iron → top and bottom blowing of converter → LF refining → vacuum treatment of RH furnace → slow cooling of billet → rolling → laminar cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com