Ferroferric oxide/polypyrrole composite material and preparation method thereof

A technology of triiron tetroxide and composite materials, applied in the field of bifunctional nano-composite fiber materials, can solve the problems of agglomeration, high electromagnetic shielding performance, and difficulty in realizing electromagnetic wave shielding materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

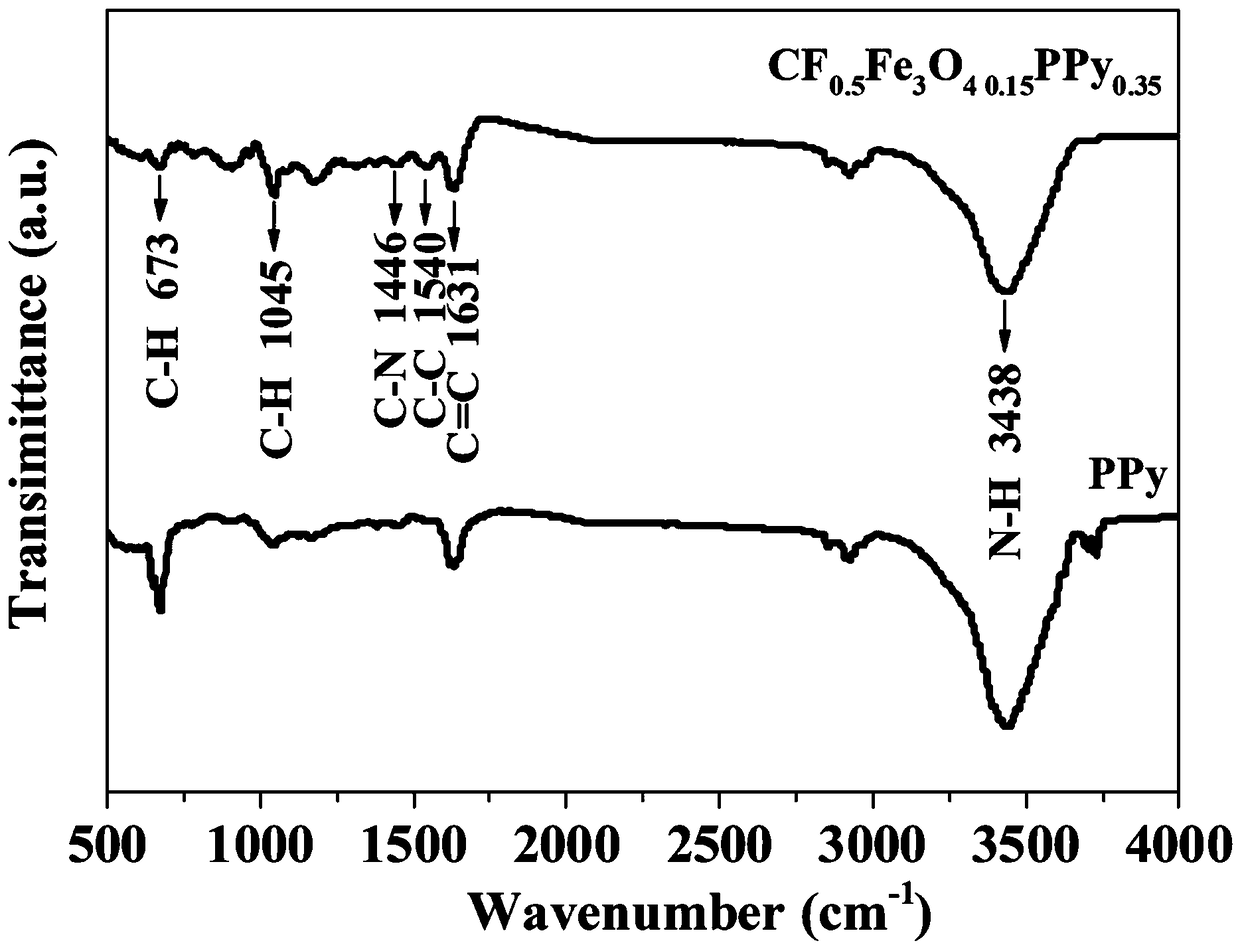

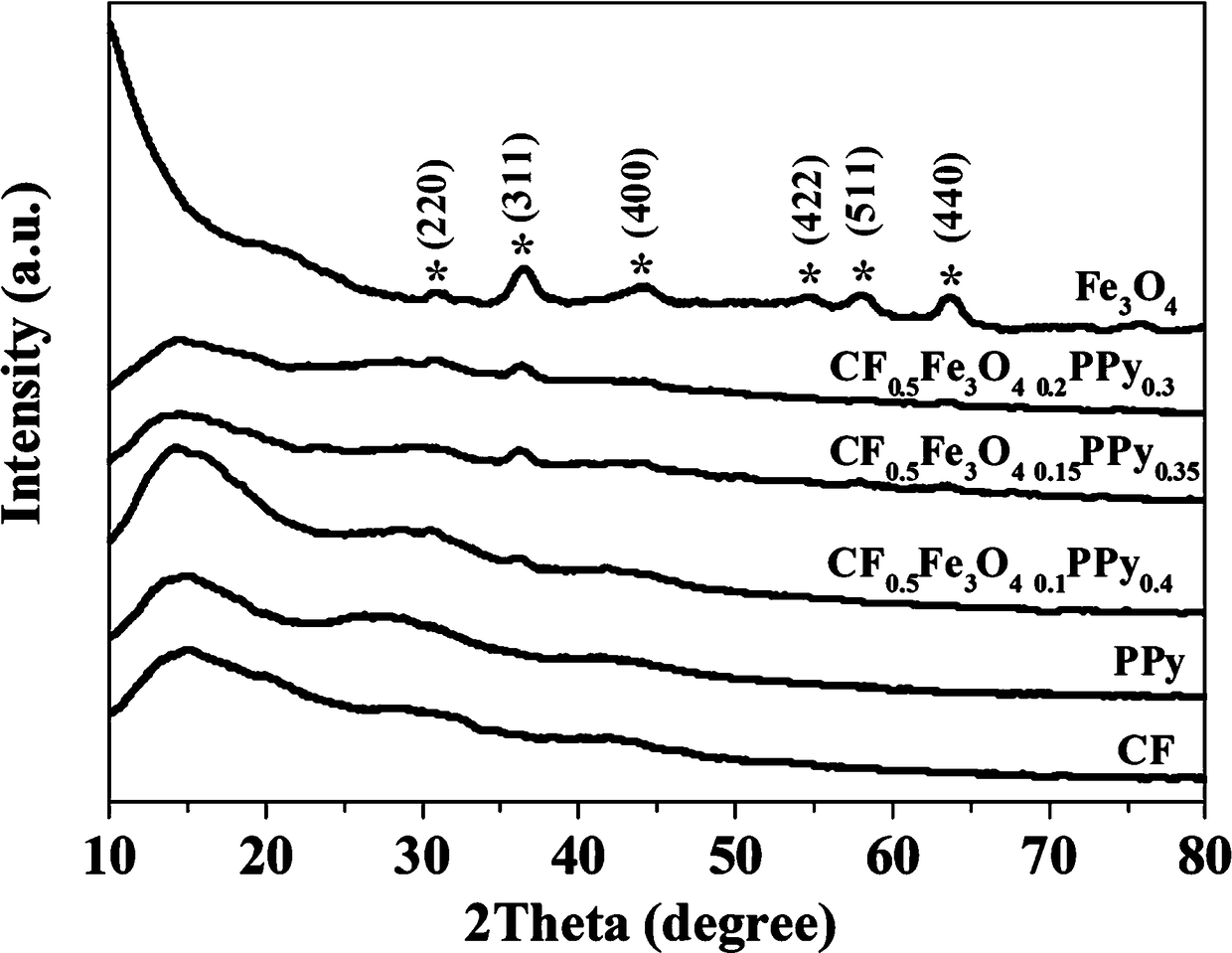

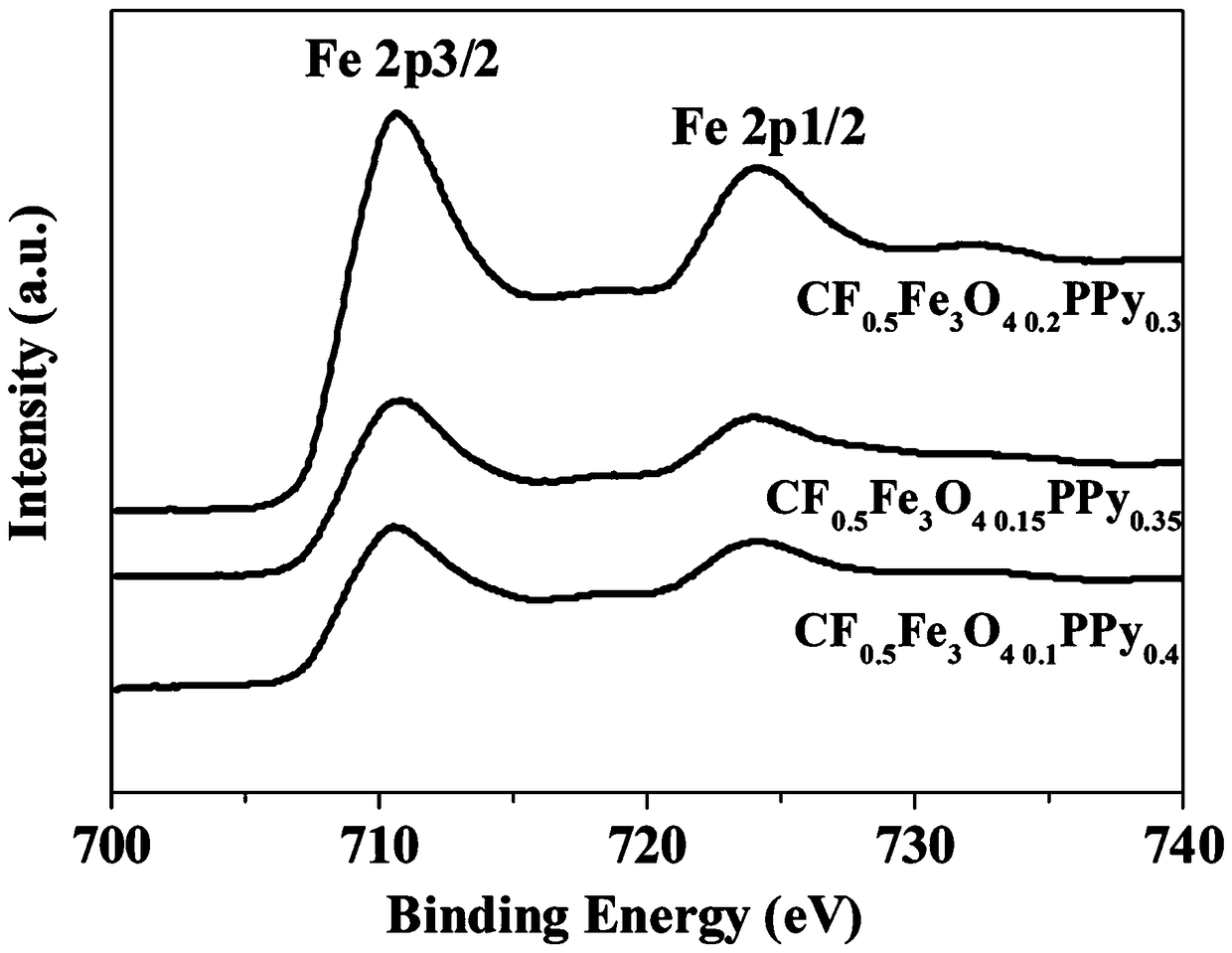

[0052] A kind of ferroferric oxide / polypyrrole nanocomposite material

[0053] (1) Stir 10kg of collagen fibers and 500kg of ethanol solution evenly, then add 3kg of nano-ferric oxide, and continue stirring in an ice-water bath at 0-5°C for 1 h;

[0054] (2) Add 7kg of pyrrole monomer to (1), keep stirring for 0.5 h in an ice-water bath at 0-5°C in the dark;

[0055] (3) Prepare ferric chloride solution, slowly add it dropwise to (2), keep stirring in an ice-water bath at 0-5°C in the dark for 20 hours, and wash, filter, and dry thoroughly after the reaction to obtain a ferric chloride solution TriFe / PPyrrole nanocomposite (CF 0.5 Fe 3 o 4 0.15 PPy 0.35 ).

[0056] (4) The resulting CF 0.5 Fe 3 o 4 0.15 PPy 0.35 They were respectively pressed into a disc with a thickness of 2 mm and a ring with a thickness of 2 mm to test their electromagnetic wave shielding performance and electromagnetic wave absorption performance.

[0057] After testing, its electromagnetic wave ...

Embodiment 2

[0059] A kind of ferroferric oxide / polypyrrole nanocomposite material

[0060] (1) Stir 10kg of collagen fibers and 500kg of ethanol solution evenly, then add 3kg of nano-ferric oxide, and keep stirring in an ice-water bath at 0-5 °C for 1 h;

[0061] (2) Add 7 kg of pyrrole monomer to (1), and keep stirring for 0.5 h in an ice-water bath at 0-5 °C in the dark;

[0062] (3) Prepare ferric chloride solution, slowly add it dropwise to (2), keep stirring in an ice-water bath at 0-5°C in the dark for 20 hours, and wash, filter, and dry thoroughly after the reaction to obtain a ferric chloride solution TriFe / PPyrrole nanocomposite (CF 0.5 Fe 3 o 4 0.15 PPy 0.35 ).

[0063] (4) The resulting CF 0.5 Fe 3 o 4 0.15 PPy 0.35 They were respectively pressed into a disc with a thickness of 1.5 mm and a ring with a thickness of 2.5 mm to test their electromagnetic wave shielding performance and electromagnetic wave absorption performance.

[0064] After testing, its electromagneti...

Embodiment 3

[0066] A kind of ferroferric oxide / polypyrrole nanocomposite material

[0067] (1) Stir 10kg of collagen fibers and 500kg of ethanol solution evenly, then add 3kg of nano-ferric oxide, and keep stirring in an ice-water bath at 0-5 °C for 1 h;

[0068] (2) Add 7 kg of pyrrole monomer to (1), and keep stirring for 0.5 h in an ice-water bath at 0-5 °C in the dark;

[0069] (3) Prepare ferric chloride solution, slowly add it dropwise to (2), keep stirring in an ice-water bath at 0-5°C in the dark for 20 hours, and wash, filter, and dry thoroughly after the reaction to obtain a ferric chloride solution TriFe / polypyrrole nanocomposite (CF 0.5 Fe 3 o 4 0.15 PPy 0.35 ).

[0070] (4) The resulting CF 0.5 Fe 3 o 4 0.15 PPy 0.35 They were respectively pressed into a disc with a thickness of 0.5 mm and a ring with a thickness of 3 mm to test their electromagnetic wave shielding performance and electromagnetic wave absorption performance.

[0071] After testing, its electromagnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com