Reinforcing filler capable of improving mechanical properties of silicon rubber

A technology of reinforcing filler and silicone rubber, which is applied in the field of new functional materials, can solve problems such as incompetence and shortage of mechanical properties, and achieve the effects of reducing usage, improving physical and mechanical properties, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

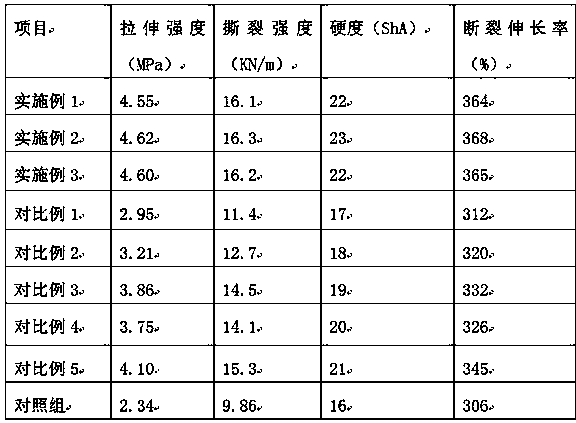

Examples

Embodiment 1

[0018] A reinforcing filler for improving the mechanical properties of silicone rubber, made of the following components in parts by weight: 5.5 parts of white carbon black, 3.8 parts of ferrous chloride tetrahydrate, 1.5 parts of hexamethyldisilazane, dimethyl 1.0 parts of formamide, 2.0 parts of borax-sodium carbonate buffer solution, 16 parts of ethanol, 2.4 parts of oleic acid, 12 parts of sodium hydroxide solution, and its preparation method comprises the following steps:

[0019] (1) Add white carbon black to a four-necked flask, add ethanol solvent, stir and mix evenly, heat up to 45°C, drop oleic acid at a rate of 35 drops / min, continue heating to 75°C after the dropwise addition, and reflux React for 2.0 hours. After the reaction is over, filter the obtained reactant with suction, and then place the product in an oven at 80°C to dry for 5 hours. The dry powder obtained is added to a porcelain boat, placed in a tube furnace, and nitrogen gas is introduced to the The ni...

Embodiment 2

[0028] A reinforcing filler for improving the mechanical properties of silicone rubber, made of the following components in parts by weight: 5.8 parts of white carbon black, 3.9 parts of ferrous chloride tetrahydrate, 1.6 parts of hexamethyldisilazane, dimethyl 1.1 parts of formamide, 2.2 parts of borax-sodium carbonate buffer solution, 17 parts of ethanol, 2.45 parts of oleic acid, 13 parts of sodium hydroxide solution, and its preparation method comprises the following steps:

[0029] (1) Add white carbon black to a four-necked flask, add ethanol solvent, stir and mix evenly, heat up to 48°C, drop oleic acid at a rate of 38 drops / min, continue heating to 76°C after dropping, and reflux Reacted for 2.2 hours. After the reaction was completed, the obtained reactant was suction filtered, and then the product was dried in an oven at 85°C for 5.5 hours to obtain a dry powder that was added to a porcelain boat, placed in a tube furnace, and nitrogen gas was introduced to the The n...

Embodiment 3

[0038] A reinforcing filler for improving the mechanical properties of silicone rubber, made of the following components in parts by weight: 6.0 parts of white carbon black, 4.0 parts of ferrous chloride tetrahydrate, 1.7 parts of hexamethyldisilazane, dimethyl 1.2 parts of formamide, 2.5 parts of borax-sodium carbonate buffer solution, 18 parts of ethanol, 2.5 parts of oleic acid, 14 parts of sodium hydroxide solution, and its preparation method comprises the following steps:

[0039] (1) Add white carbon black to a four-necked flask, add ethanol solvent, stir and mix evenly, heat up to 50°C, drop oleic acid at a rate of 40 drops / min, continue heating to 78°C after dropping, and reflux React for 2.5 hours. After the reaction is over, filter the obtained reactant with suction, then place the product in a 90°C oven and dry it for 6 hours to obtain a dry powder that is added to a porcelain boat, placed in a tube furnace, and nitrogen gas is introduced to the The nitrogen gas int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com