Preparation method of abrasion-resistant and aging-resistant flame retardant rubber filled and modified by montmorillonite-hydrotalcite-fly ash

A technology of flame retardant rubber and hydrotalcite is applied in the field of rubber product materials, which can solve the problems of single, high cost, and complicated application methods of ash modification, and achieve the effects of simple process, low cost and obvious flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

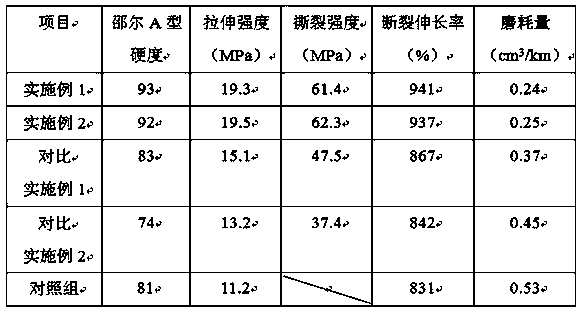

Examples

Embodiment 1

[0033] A method for preparing a wear-resistant and aging-resistant flame-retardant rubber filled with montmorillonite-hydrotalcite-fly ash is characterized in that it comprises the following steps:

[0034] (1) Composite organically modified montmorillonite:

[0035] Add deionized water to 3 parts of sodium montmorillonite at a ratio of 1:10, stir and disperse in a constant temperature water bath at 78-82°C for 25 minutes, add a compound surface modifier and mix, continue to stir and disperse for 3 hours, cool to room temperature, and filter with suction. Dry it in a constant temperature drying oven at 80-83°C, grind it through a 200-mesh sieve, and obtain a composite organically modified montmorillonite;

[0036] (2) Modified nitrate hydrotalcite by ion exchange method:

[0037] Add deionized water to 4 parts of nitrate-type hydrotalcite at a ratio of 1:60, blow in nitrogen, and heat at 90-93°C

[0038] After 2-3 hours, add 4 parts of sodium p-styrenesulfonate, continue hea...

Embodiment 2

[0048] A method for preparing a wear-resistant and aging-resistant flame-retardant rubber filled with montmorillonite-hydrotalcite-fly ash is characterized in that it comprises the following steps:

[0049] (1) Composite organically modified montmorillonite:

[0050] Add deionized water to 6 parts of sodium montmorillonite at a ratio of 1:10, stir and disperse in a constant temperature water bath at 78-82°C for 35 minutes, add a compound surface modifier to mix, continue to stir and disperse for 4 hours, cool to room temperature, and filter with suction. Dry it in a constant temperature drying oven at 80-83°C, grind it through a 200-mesh sieve, and obtain a composite organically modified montmorillonite;

[0051] (2) Modified nitrate hydrotalcite by ion exchange method:

[0052] Add deionized water to 5 parts of nitrate-type hydrotalcite at a ratio of 1:60, blow in nitrogen, and heat at 90-93°C

[0053] After 3 hours, add 5 parts of sodium p-styrenesulfonate, continue heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com