A production device and method for electronic grade phosphorus pentoxide

A technology of phosphorus pentoxide and electronic grade, which is applied in the field of production equipment of electronic grade phosphorus pentoxide, can solve the problems of high equipment requirements, large impact on product quality, large equipment impact, etc., and achieves good quality stability and process technology. Easy-to-control, mild combustion response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

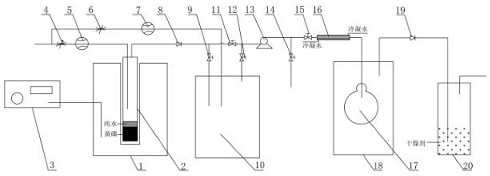

[0022] Example 1 Production device of electronic grade phosphorus pentoxide

[0023] Such as figure 1 The production device of the electronic grade phosphorus pentoxide consists of a primary reactor 2, a temperature controller 3, a heater 1, a secondary reactor 10, a large flow fan 13, a condenser 16, a receiver 18 and a dryer 20. , wherein: the primary reactor 2 is placed in the heater 1, one end of the primary reactor 2 is connected to a purified oxygen intake pipe with air pressure regulating valves 4 and 6 and flow control, and the other end is connected to the one-way control valve 8 and then connected The secondary reactor 10; the secondary reactor 10 is provided with two gas inlets and a gas outlet, and the two gas inlets are respectively connected with the inert gas inlet pipe and the gas outlet pipe of the primary reactor 2 with a one-way control valve 8. The air port is connected to the large-flow fan 13, and the outlet end of the large-flow fan 13 is connected to t...

Embodiment 2

[0026] Embodiment 2 Using the production device of Embodiment 1, first use purified nitrogen to remove the air in the equipment, and prepare electronic grade phosphorus pentoxide according to the following steps:

[0027] (1) Transfer 1.5kg of liquid high-purity yellow phosphorus with a purity of 6N to the primary reactor 2 by siphon, cover it with ultra-high-purity water, open the pipeline valve 11 and exhaust valve 14 in the device, and run the large-flow fan 13, At the same time, adjust the temperature controller 3 to control the heater 1 to heat the primary reactor at 105°C until the trace water in the pure water and yellow phosphorus evaporates completely and then stop heating;

[0028] (2) Open the secondary reactor inlet valve 9, the secondary reactor outlet valve 12 and the receiving valve 15, close the exhaust valve 14 and the pipeline valve 11 in the device; open the A air pressure regulating valve 4 and B air pressure on the intake pipe Regulating valve 6, the high-...

Embodiment 3

[0034] Embodiment 3 Using the production device of Embodiment 1, first use purified argon to remove the air in the equipment, and prepare electronic grade phosphorus pentoxide according to the following steps:

[0035](1) Transfer 2 kg of liquid high-purity yellow phosphorus with a purity of 6N to the primary reactor 2 by siphon, cover it with ultra-high-purity water, open the pipeline valve 11 and exhaust valve 14 in the device, and run the large-flow fan 13, and at the same time Adjust the temperature controller 3 to control the heater 1 to heat the primary reactor at 110°C until the trace water in the pure water and yellow phosphorus evaporates completely and then stop heating;

[0036] (2) Open the secondary reactor inlet valve 9, the secondary reactor outlet valve 12 and the receiving valve 15, close the exhaust valve 14 and the pipeline valve 11 in the device; open the A air pressure regulating valve 4 and B air pressure on the intake pipe Regulating valve 6, the high-pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com