Nutritional recombinant rice and preparation method

A technology of recombining rice and nutrition, which is applied to the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems of large nutrient loss, intolerance to cooking, etc., achieve comprehensive nutritional value, improve the degree of gelatinization, Nutrient rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

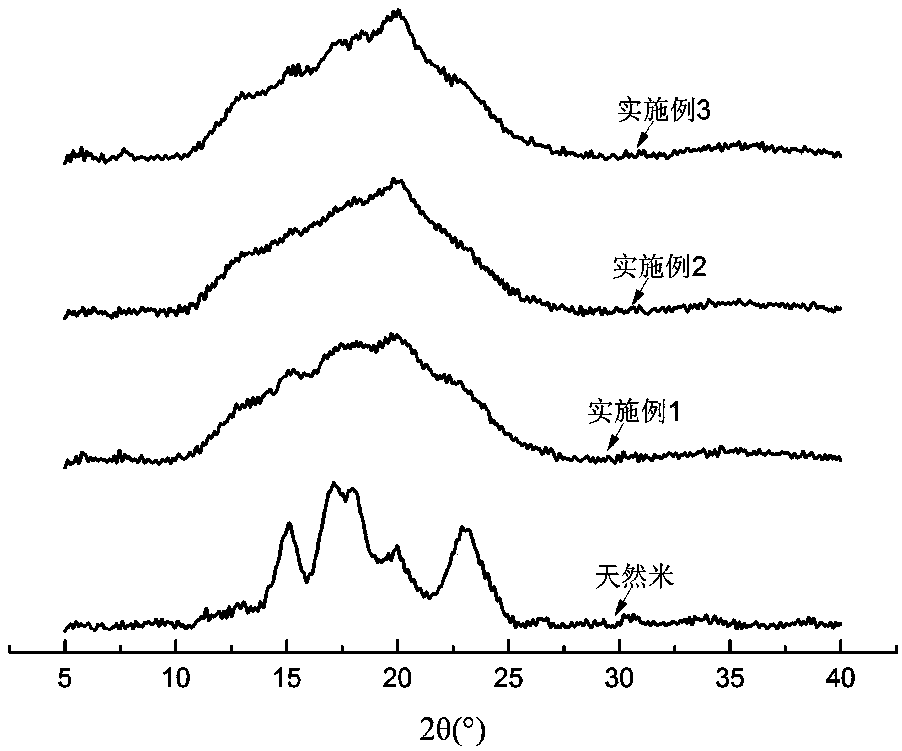

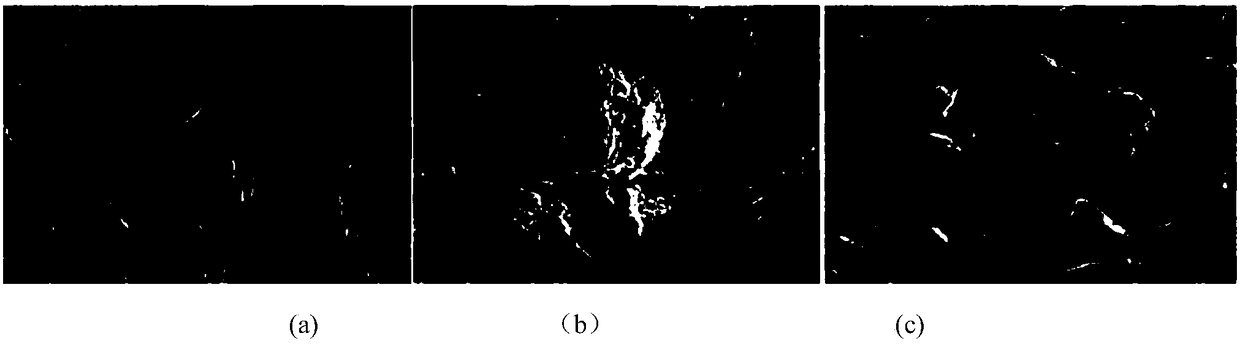

Embodiment 1

[0037] The application provides a nutritionally recombined rice and a production method, the specific steps are as follows:

[0038]Put the quinoa into clean water, wash it clean, and soak it for 10 minutes at a temperature of 20°C. After the taro head is peeled, add water and beat according to the material-to-water ratio of 1:2 (W / W). The pretreated quinoa and taro head are dried and crushed through a 100-mesh sieve. Quinoa flour ball mill processing parameters: the sample volume of the ball mill jar is 200mL, the ball mill speed is 300r / min, the grinding time is 60min, and the ball-to-material ratio is 4:1. The whole taro powder and quinoa powder were pre-cured by microwave irradiation. The microwave power of the whole taro powder was 100W, the microwave pre-curing time was 4min, and the moisture content of the material was 10%. The microwave power of quinoa flour was 200W, and the microwave pre-curing time was 5min. Moisture 15%. 1800g of quinoa powder, 200g of taro head ...

Embodiment 2

[0040] The application provides a nutritionally recombined rice and a production method, the specific steps are as follows:

[0041] Put the quinoa into clean water, wash it, and then soak it for 20 minutes, and the soaking temperature is 30°C. After the taro head is peeled, add water and beat according to the material-to-water ratio of 1:2.5 (W / W). The pretreated quinoa and taro head are dried and crushed through a 100-mesh sieve. Quinoa flour ball mill processing parameters: the sample volume of the ball mill tank is 400mL, the ball mill speed is 400r / min, the grinding time is 90min, and the ball-to-material ratio is 6:1. The whole powder of taro head and quinoa powder were pre-cured by microwave irradiation. The microwave power of the whole powder of taro head was 200W, the microwave pre-curing time was 3min, and the moisture content of the material was 20%. The microwave power of quinoa flour was 300W, and the microwave pre-curing time was 4min. Moisture 25%. Mix 1600g o...

Embodiment 3

[0043] The application provides a nutritionally recombined rice and a production method, the specific steps are as follows:

[0044] Put the quinoa into clean water, wash it clean, and then soak it for 30 minutes, and the soaking temperature is 40°C. After the taro head is peeled, add water and beat according to the material-to-water ratio of 1:3 (W / W). The pretreated quinoa and taro head are dried and crushed through a 100-mesh sieve. Quinoa flour ball mill processing parameters: the sample volume of the ball mill tank is 600mL, the ball mill speed is 500r / min, the grinding time is 120min, and the ball-to-material ratio is 8:1. The whole taro powder and quinoa powder were pre-cured by microwave irradiation. The microwave power of the whole taro powder was 300W, the microwave pre-curing time was 2 minutes, and the moisture content of the material was 30%. The microwave power of quinoa flour was 400W, and the microwave pre-curing time was 3 minutes. Moisture 35%. 1400g of qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com