Polylactic acid-starch blended material and preparation method thereof

A technology of polylactic acid and starch, which is applied in the field of polylactic acid starch blend materials and its preparation, can solve problems such as poor interface compatibility, achieve the effect of enhancing hydrophobicity, reducing production costs, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

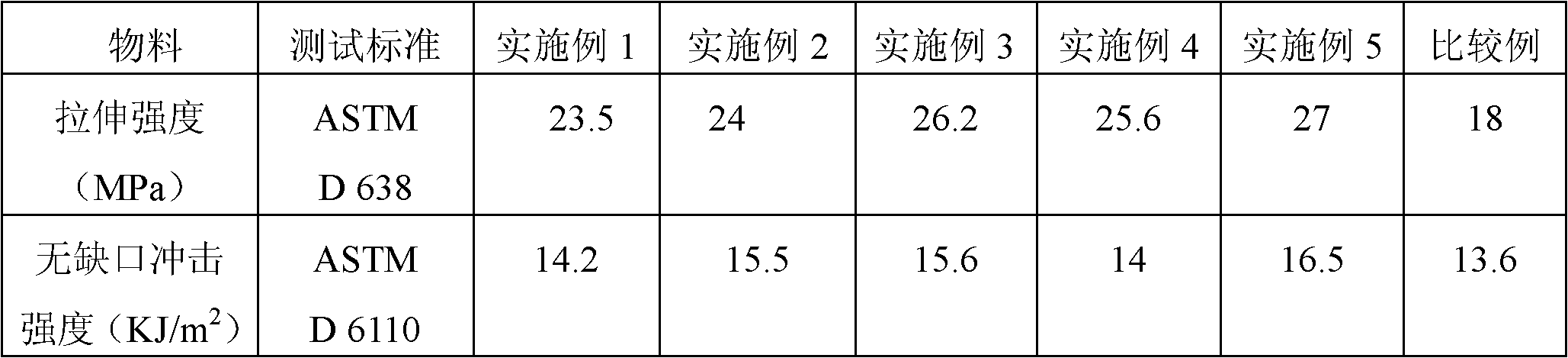

Examples

Embodiment 1

[0027] (1) Add 1000 g of pretreated starch, 11 g of maleic anhydride, 98 g of dibutyl phthalate, and 2.2 g of silane coupling agent vinyltrimethoxysilane into a high-speed mixer to stir and mix at room temperature for a mixing time of 10 minute;

[0028] (2) 1111g of the mixture obtained in step (1) is directly mixed with 2075g of extrusion-grade polylactic acid PLLA, and 107697g of antioxidant is granulated through a twin-screw extruder. The aspect ratio of the twin-screw extruder is 40:1, and the temperature in each zone The control is 120, 155, 175, 180, 180, 175°C.

[0029] The pretreatment starch treatment step is: disperse 1000g of cornstarch into 19L of distilled water to make a starch suspension with a concentration of 5%, pour it into an ultrahigh pressure container for 500MPa ultrahigh pressure treatment for 10h, and then dehydrate and dry at room temperature. 0.5%, to obtain pretreated starch.

[0030] Thoroughly dry the pellets obtained in the above examples in a...

Embodiment 2

[0032] (1) Add 1000 g of pretreated starch, 62.5 g of diphenylmethane diisocyanate, 162.5 g of dibutyl phthalate, and 25 g of isopropyl triisostearyl titanate as a titanate coupling agent into a high-speed mixer. The mixer is stirred and mixed at room temperature, and the mixing time is 30 minutes;

[0033] (2) 1250g of the mixture obtained in step (1) was granulated through a twin-screw extruder, mixed with 7179g of extrusion-grade polylactic acid PDLA and 101016.9g of antioxidant, and granulated again. The length-to-diameter ratio of the twin-screw extruder is 40:1, and the temperature in each zone is controlled at 120, 155, 175, 180, 180, and 175°C.

[0034] The pretreatment starch treatment step is: disperse 1000g of potato starch into 9L of distilled water to make a starch suspension with a concentration of 10%, pour it into an ultrahigh pressure container for 700MPa ultrahigh pressure treatment for 15h, and then dehydrate and dry at room temperature. 0.5%, to obtain pre...

Embodiment 3

[0037] (1) Add 1000g of pretreated starch, 114g of formamide, 286g of polyethylene glycol, and 28.6g of isopropyl titanate coupling agent tris(dioctylpyrophosphoryloxy)titanate into a high-speed mixer and stir Mix at room temperature for 40 minutes;

[0038] (2) 1428g of the mixture obtained in step (1) was granulated through a twin-screw extruder, mixed with 608g of extrusion-grade polylactic acid PLLA and 10764g of antioxidant according to the proportion and then granulated again. The length-to-diameter ratio of the twin-screw extruder is 30:1, and the temperature in each zone is controlled at 120, 155, 175, 180, 180, and 175°C.

[0039] The pretreatment starch treatment step is: disperse 1000g of wheat starch into 11.5L of distilled water to make a starch suspension with a concentration of 8%, pour it into an ultra-high pressure container for 800MPa ultra-high pressure treatment for 20h, and then dehydrate and dry the water content at room temperature <0.5%, get pretreated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com