Method for preparing vermicelli convenient food and vermicelli convenient food

A technology of instant food and vermicelli, which is applied in the field of food processing, can solve the problems of high refrigeration equipment requirements, long processing time, and increased costs, and achieve the effects of shortened rehydration time, simple method, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: the inventive method prepares vermicelli class instant food

[0022] 1. Ingredients

[0023] Prepare raw material sweet potato starch (accounting for 70 parts by weight), potato starch (accounting for 20 parts by weight), cornstarch (accounting for 10 parts by weight) and prepare 100kg instant vermicelli according to the following steps.

[0024] 2. Mixing

[0025] Fill the mixing tank with tap water accounting for 10% of the total water consumption, then start the stirring device, add raw materials and water at a uniform speed, so that the concentration of the slurry is 23 0 Be'.

[0027] Spread the slurry on the conveying device, according to the width of the conveyor belt, the width of the slurry is 1000mm.±50mm, and the thickness is 1.0±0.2mm.

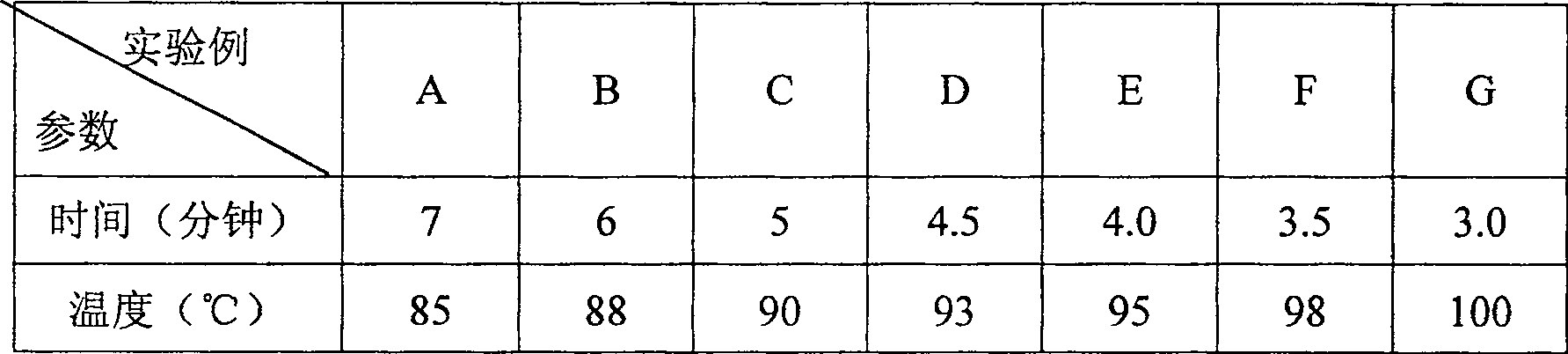

[0028] 4. Steaming pulp

[0029] Steam pulp at 94°C for 3.5 minutes.

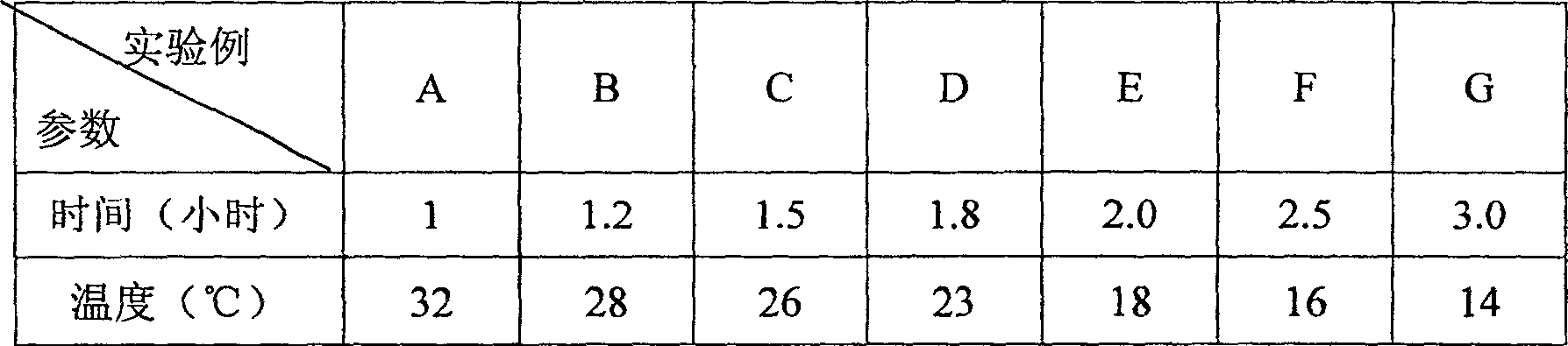

[0030] 5. Pre-cooling

[0031] Pre-cool at room temperature.

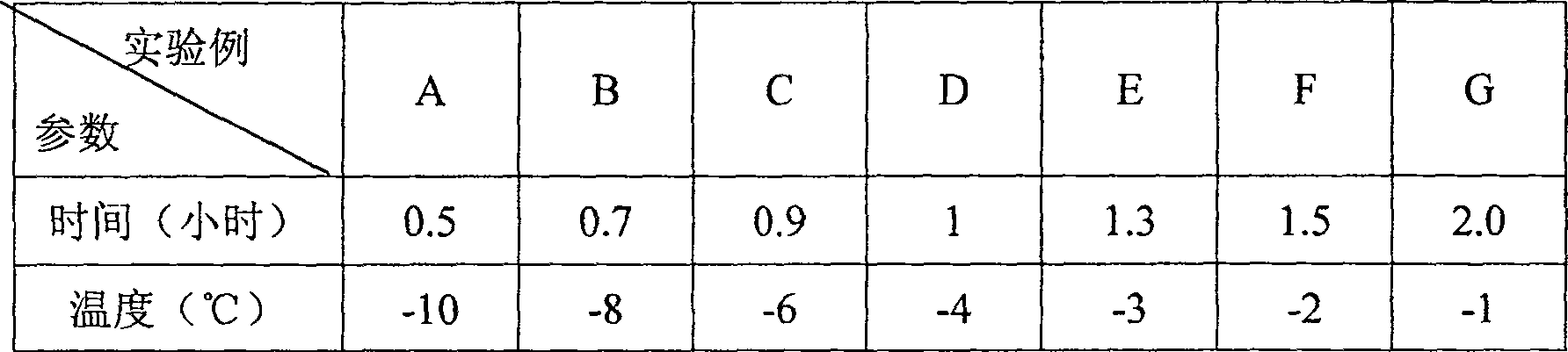

[0032] 6. Freezing

[0033] The fr...

Embodiment 2

[0038] Embodiment two: the preparation of vermicelli class instant food of the present invention

[0039] 1. Ingredients

[0040] Prepare raw material sweet potato starch (accounting for 60 parts by weight), potato starch (accounting for 25 parts by weight), cornstarch (accounting for 15 parts by weight) and prepare 100kg instant vermicelli according to the following steps.

[0041] 2. Mixing

[0042] Fill the mixing tank with tap water accounting for 10% of the total water consumption, then start the stirring device, add raw materials and water at a uniform speed, so that the concentration of the slurry is 24 0 be

[0044] Spread the slurry on the conveying device, according to the width of the conveyor belt, the width of the slurry is 1000mm.±50mm, and the thickness is 1.0±0.2mm.

[0045] 4. Steaming pulp

[0046] Steam pulp at 96°C for 2.8 minutes.

[0047] 5, 5, pre-cooling

[0048] Pre-cooling at room temperature, the temperature is: ...

Embodiment 3

[0055] Embodiment three: the preparation of vermicelli class instant food of the present invention

[0056] 1. Ingredients

[0057] Prepare raw material sweet potato starch (accounting for 80 parts by weight), potato starch (accounting for 15 parts by weight), cornstarch (accounting for 5 parts by weight) and prepare 100kg instant vermicelli according to the following steps.

[0058] 2. Mixing

[0059] Fill the mixing tank with tap water accounting for 10% of the total water consumption, then start the stirring device, add raw materials and water at a uniform speed, so that the concentration of the slurry is 23 0 Be'

[0061] Spread the slurry on the conveying device, according to the width of the conveyor belt, the width of the slurry is 1000mm.±50mm, and the thickness is 1.0±0.2mm.

[0062] 4. Steaming pulp

[0063] Steam pulp at 100°C for 3 minutes.

[0064] 5. Pre-cooling

[0065] Pre-cool at room temperature.

[0066] 6. Freezing

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com