Battery based on fluorine doped graphene nanosheets

A graphene nanosheet, fluorine doping technology, applied in the field of materials, to achieve the effect of simple doping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

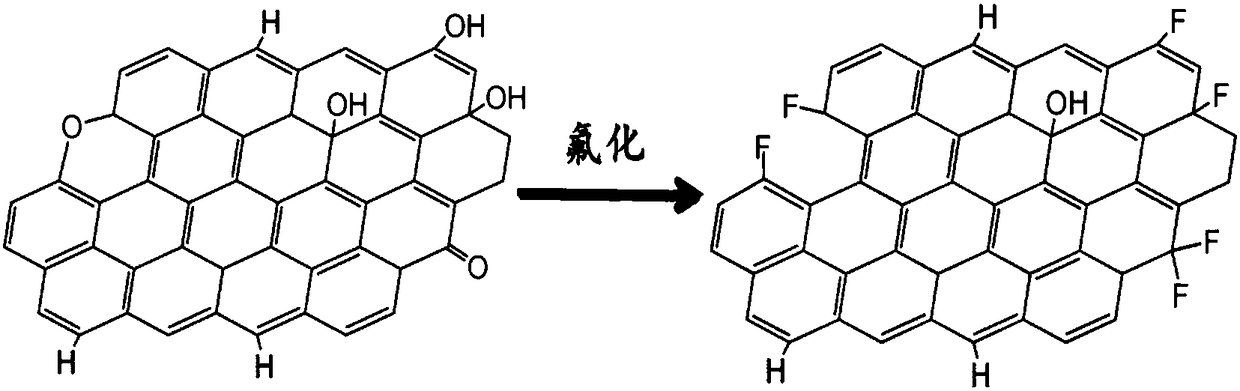

Problems solved by technology

Method used

Image

Examples

Embodiment 1

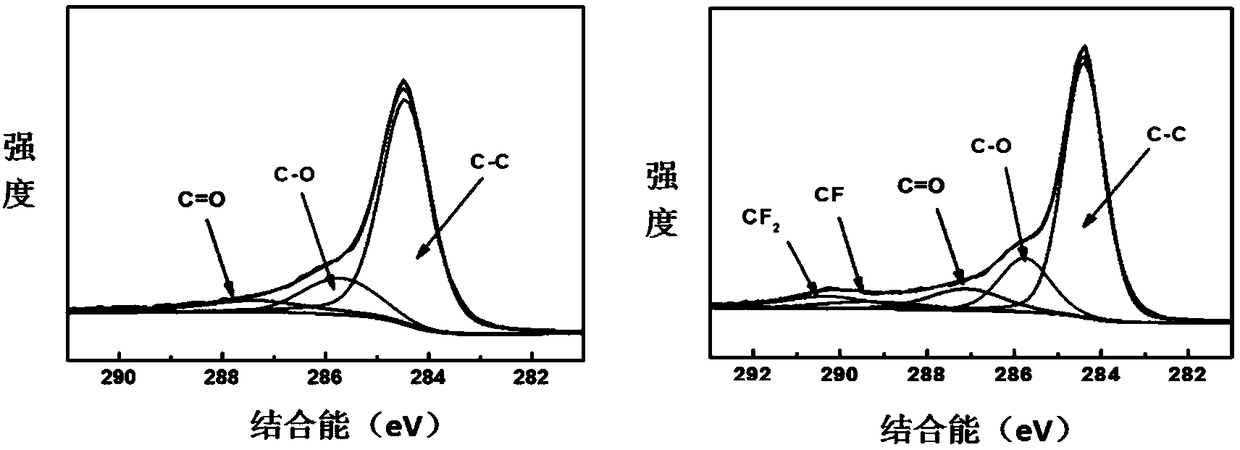

[0024] Use reduced graphene oxide and ethanol as raw materials to prepare rGN ethanol dispersion with a concentration of 1 mg / ml, add 1 mL of hydrofluoric acid, and mix well by ultrasonication for 10 minutes, then pour the mixture into 50 mL of polytetrafluoroethylene-lined water In the hot kettle, use a muffle furnace to heat the hydrothermal kettle to 150° C. for 24 hours. After the hydrothermal kettle was naturally cooled to room temperature, the solution was taken out and centrifuged at 10000rmp for 20min with a centrifuge, and the obtained powder was redispersed in deionized water and ethanol, and centrifuged several times until the pH of the aqueous solution reached neutral. Then the obtained powder was suction-filtered, placed in a vacuum oven, and dried at 60°C for 24 hours to obtain -CF 2 Fluorine-doped graphene nanosheets (F-rGO).

Embodiment 2

[0026] Use reduced graphene oxide and ethanol as raw materials to prepare rGN ethanol dispersion with a concentration of 2 mg / ml, add 5 mL of hydrofluoric acid, and mix well by ultrasonication for 10 minutes, then pour the mixture into 50 mL of polytetrafluoroethylene-lined water In the hot kettle, use a muffle furnace to heat the hydrothermal kettle to 120° C. for 36 hours. After the hydrothermal kettle was naturally cooled to room temperature, the solution was taken out and centrifuged at 8000rmp for 20 minutes with a centrifuge, and the obtained powder was redispersed in deionized water and ethanol, and centrifuged several times until the pH of the aqueous solution reached neutral. Then the obtained powder was suction-filtered, placed in a vacuum oven, and dried at 60°C for 24 hours to obtain -CF 2 Fluorine-doped graphene nanosheets (F-rGO).

Embodiment 3

[0028] Use reduced graphene oxide and ethanol as raw materials to prepare rGN ethanol dispersion with a concentration of 3 mg / ml, add 10 mL of hydrofluoric acid, and mix well by ultrasonication for 10 minutes. In the hot kettle, use a muffle furnace to heat the hydrothermal kettle to 180° C. for 12 hours. After the hydrothermal kettle was naturally cooled to room temperature, the solution was taken out and centrifuged at 10000rmp for 20min with a centrifuge, and the obtained powder was redispersed in deionized water and ethanol, and centrifuged several times until the pH of the aqueous solution reached neutral. Then the obtained powder was suction-filtered, placed in a vacuum oven, and dried at 60°C for 24 hours to obtain -CF 2 Fluorine-doped graphene nanosheets (F-rGO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com