P-type gate enhanced HEMT device and manufacturing method thereof

A manufacturing method and enhanced technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficult process control, current collapse, and saturation current drop, and solve the problems of difficult process control and current collapse Improvement, off-state leakage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] A method for manufacturing a p-type gate enhanced HEMT device, comprising the steps of:

[0091] 1) Grown by metal organic compound chemical vapor deposition (MOCVD) such as Figure 5 The epitaxial structure shown; the substrate is made of Si with a thickness of 400 μm, the buffer layer is made of high-resistance GaN with a thickness of 4200 nm, the thickness of GaN in the AlGaN / GaN heterostructure is 260 nm, and the thickness of AlGaN is 18 nm. The content of Al components in AlGaN is 18%, and the thickness of p-GaN is 70nm;

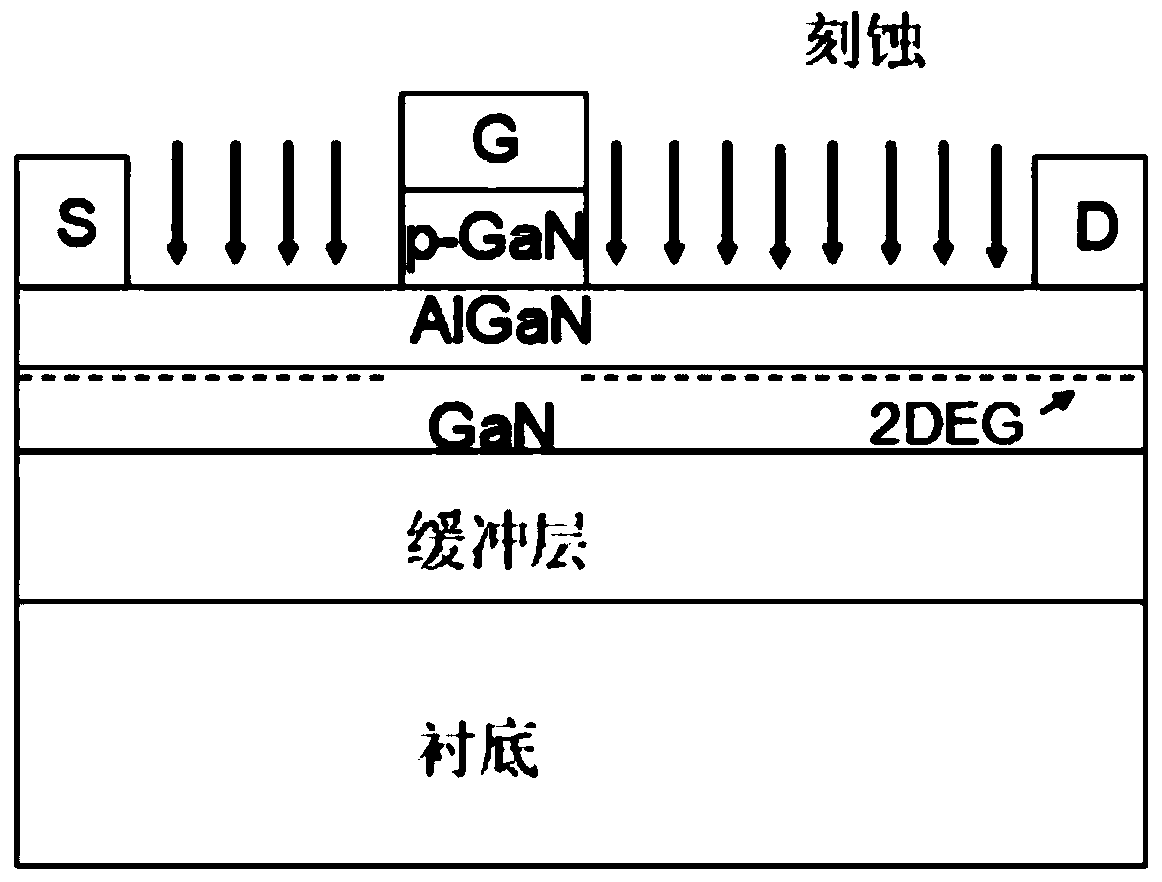

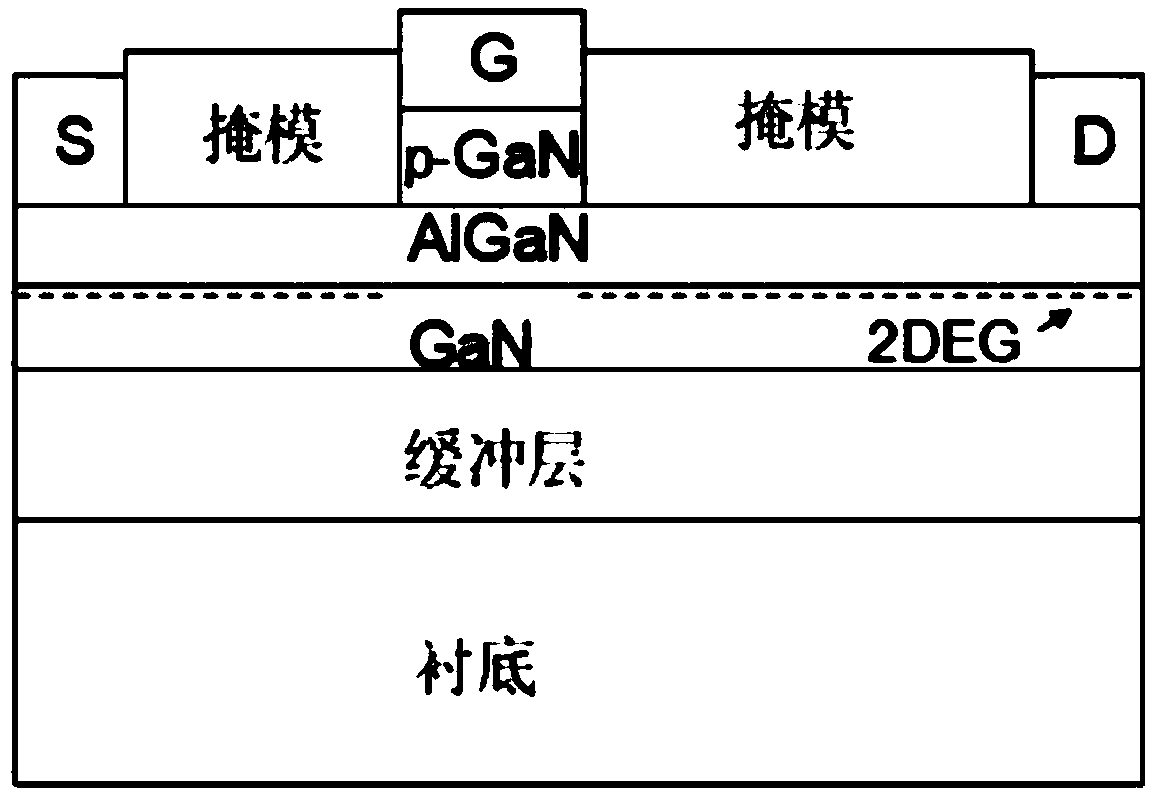

[0092] 2) Plasma etching is used to remove the p-GaN in the source region and the drain region, and the device structure after etching is as follows Figure 6 As shown; the etching area can be determined by photolithography, and the specific steps of photolithography include pretreatment, uniform glue, pre-baking, exposure and development;

[0093] 3) Deposit Ti / Al / Ni / Au on the source region and the drain region by electron beam evaporation as ...

Embodiment 2

[0098] A method for manufacturing a p-type gate enhanced HEMT device, comprising the steps of:

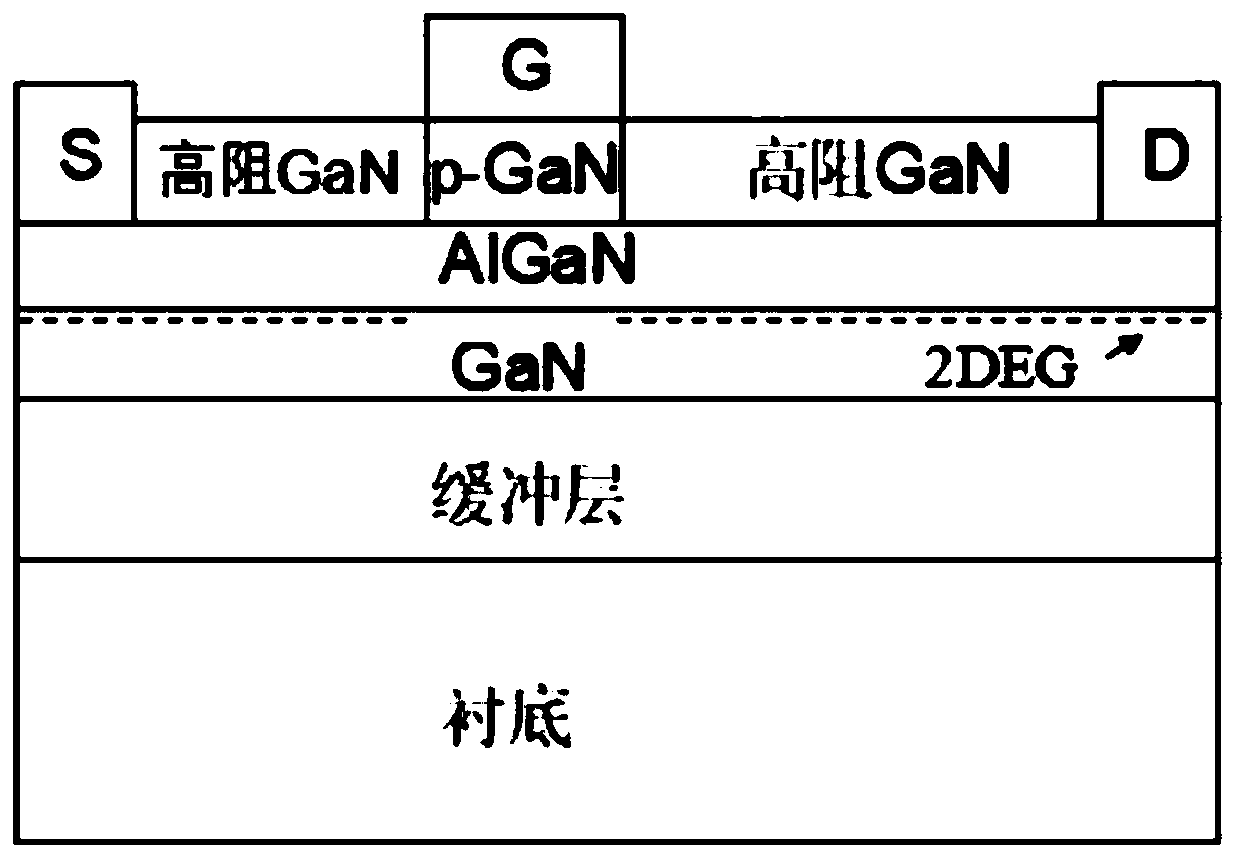

[0099] 1) The substrate / buffer layer / AlGaN / GaN heterostructure / high-resistance GaN epitaxial structure is grown by metal-organic compound chemical vapor deposition (MOCVD); the substrate is made of Si with a thickness of 400 μm, and the buffer layer is made of high-resistance GaN , the thickness is 4200nm, the thickness of GaN in AlGaN / GaN heterostructure is 260nm, the thickness of AlGaN is 18nm, the content of Al component in AlGaN is 18%, and the thickness of high resistance GaN is 70nm;

[0100] 2) Use plasma etching to remove the high-resistance GaN in the source region and the drain region. The etching region can be determined by photolithography. The specific steps of photolithography include pretreatment, glue leveling, pre-baking, exposure and development;

[0101] 3) Deposit Ti / Al / Ni / Au on the source region and the drain region by electron beam evaporation as the source el...

Embodiment 3

[0106] The manufacturing method of the p-type gate-enhanced HEMT device in this embodiment is basically the same as that in Embodiment 1, the difference is that after the source electrode and the drain electrode are prepared, the gate electrode can be prepared first, and then the etching process is used The p-GaN between the gate electrode and any one of the source electrode and the drain electrode is thinned, and finally the thinned p-GaN is passivated to form high-resistance GaN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com