Complex-surface recast-layer-free single/group-hole multi-station electric spark-electrolytic machine tool

An electrolytic machining machine tool and a technology for complex curved surfaces, which are applied in electric machining equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult-to-machine small single/group holes without recasting layer processing, etc., to improve machining accuracy. and surface quality, improve processing efficiency, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

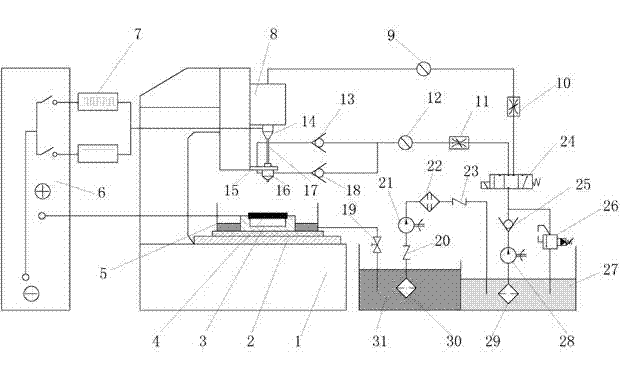

[0031] Below in conjunction with accompanying drawing, invention is described in detail.

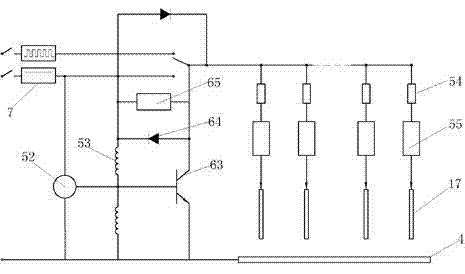

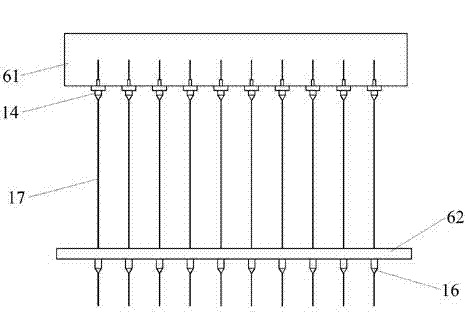

[0032] Such as figure 1 , Figure 4 As shown, the complex surface of the present invention has no recasting layer single / group hole multi-station EDM-electrolytic machining machine tool comprising a machine bed 1, a workbench 2, a fixture 3, a workpiece 4, a working groove 5, a machine tool spindle 8, and an electrode The clamping device 14, the flushing device support 15, and the tool electrode 17 form the machine tool body. The cathode device is composed of the tool electrode 17, the electrode clamping device 14, and the guide device 57; the flushing device 16, the pressure gauge 9, 12, the pressure regulating device 10, 11, the one-way valve 13, 18, 25, the stop valve 19, Plunger metering pump 21, fine filter 22, check valves 20, 23, electromagnetic reversing valve 24, overflow valve 26, flushing pump 28, filters 29, 30, clean liquid tank 27, turbid liquid tank 31 And pipelines for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com