Aluminium alloy welding material rod blank production device and working process

A production device and technology of aluminum alloy, applied in the field of aluminum alloy production, can solve the problems of high production cost, large investment, increased burning loss and volatilization of alloy elements, etc., and achieve simple structure and production process, broad market prospects, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

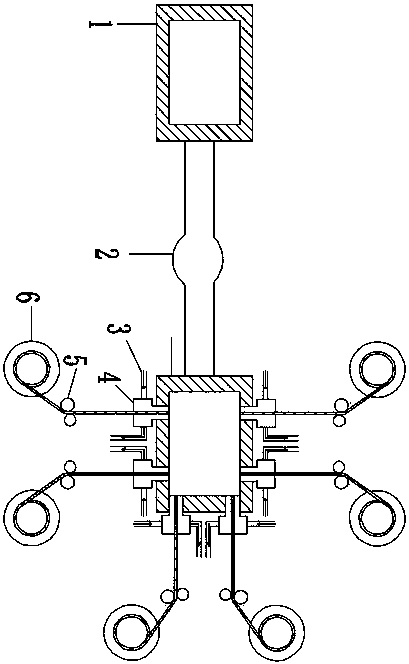

[0020] see figure 1 , a production device for aluminum alloy welding rod blanks, including a melting reverberatory furnace, an electromagnetic stirring device, a cooling cycle mechanism, an alloy crystallizer, a traction device and a wire take-up mechanism, the melting reverberatory furnace is connected with the electromagnetic stirring device, and the copper alloy crystallizer It is connected with the take-up mechanism through the traction device, and the cooling circulation mechanism surrounds the alloy crystallizer. The cooling circulation mechanism adopts circulating cooling water pipes, and the alloy crystallizer is installed on the casting holding furnace. The smelting reverberatory furnace includes a smelting furnace, a degassing device and a refining furnace, and is an integrated structure.

[0021] The working process of the production d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com