Polylactic acid-lignin-starch composite material and preparation method therefor

A composite material and lignin technology, which is applied in the field of polylactic acid-lignin-starch composite material and its preparation, can solve the problems of lack of reactive functional groups, poor brittleness of PLA, non-hydrophilicity, etc., and achieve simple operation and high effect Good, improve the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 polylactic acid-lignin-starch composite material

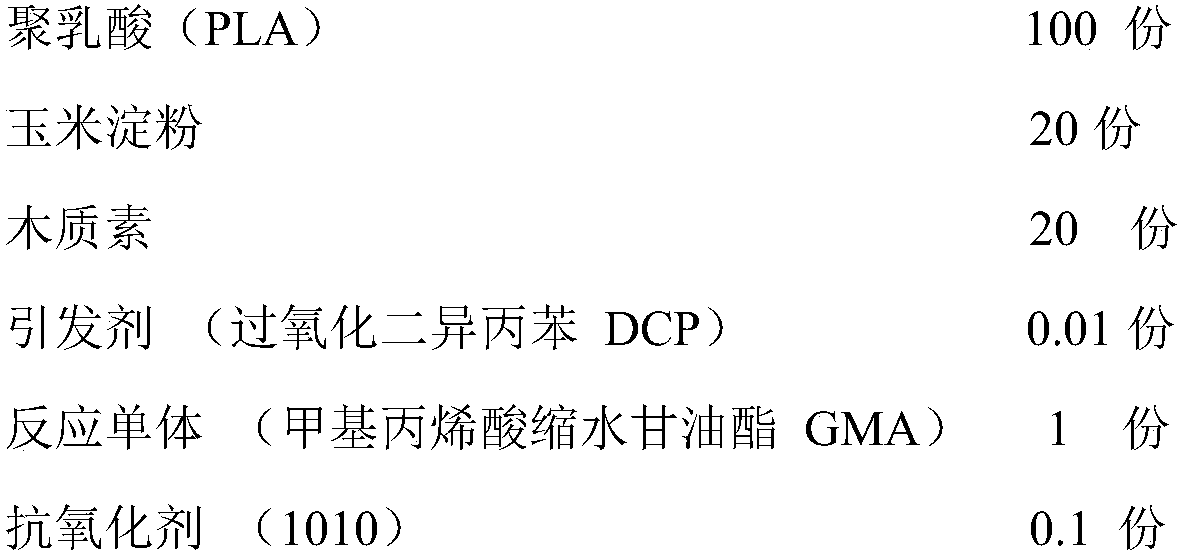

[0032] (1) Calculated in parts by mass, its composition and content are as follows:

[0033]

[0034] (2) above-mentioned formula reacts according to the following steps:

[0035] (1) First weigh the PLA and lignin in proportion, and mix them evenly at room temperature;

[0036] (2) After mixing the weighed DCP, GMA, and 1010 evenly, they are added to the reactive extruder together with the PLA and lignin mixture. The temperature of the extruder is set at 150°C, and the screw speed is 400RPM. Granulating to prepare PLA lignin composite material particles. The above composite material particles are injection molded (injection temperature is 160-180°C, injection pressure is 40-80MPa, injection speed is 50-150mm / s, holding pressure is 40-50MPa, holding time is 5S, cooling time is 15S) Standard test specimens were prepared for use.

Embodiment 2

[0037] The preparation of embodiment 2 polylactic acid-lignin-starch composite material

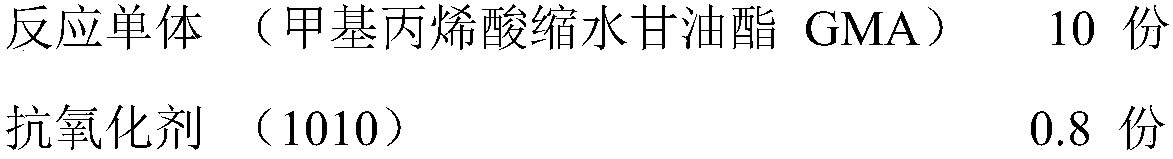

[0038] (1) Calculated in parts by mass, its composition and content are as follows:

[0039]

[0040]

[0041] (2) above-mentioned formula reacts according to the following steps:

[0042] (1) First weigh PLA, lignin and starch in proportion, and mix them evenly at room temperature;

[0043] (2) After mixing the weighed DCP, GMA, and 1010 evenly, they are added to the reaction extruder together with the PLA and lignin mixture. The temperature of the extruder is set at 190°C, and the screw speed is 300RPM. Granulating to prepare PLA lignin composite material particles. The above-mentioned composite material particles were injection molded (the injection molding process was the same as in Example 1) to prepare standard test specimens for future use.

Embodiment 3

[0044] The preparation of embodiment 3 polylactic acid-lignin-starch composite material

[0045] (1) Calculated in parts by mass, its composition and content are as follows:

[0046]

[0047] (2) above-mentioned formula reacts according to the following steps:

[0048] (1) First weigh PLA, lignin and starch in proportion, and mix them evenly at room temperature;

[0049] (2) After mixing the weighed DCP, GMA, and 1010 evenly, they are added to the reaction extruder together with the PLA and lignin mixture. The temperature of the extruder is set at 160°C, and the screw speed is 100RPM. Granulating to prepare PLA lignin starch composite material particles. The above-mentioned composite material particles were injection molded (the injection molding process was the same as in Example 1) to prepare standard test specimens for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com