Preparation method of polymer-based PTC trace heating tape

A polymer-based, heat-tracking technology, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of large starting current, flammability, low resistivity, etc., to enhance adhesion, increase The effects of stability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of polymer-based PTC heating tape in the present embodiment, the concrete steps are as follows:

[0027] 1) Reinforcing material pretreatment: First, place the alkali-free glass fiber in a muffle furnace for heat treatment at 410 °C for 2 minutes, and then put it into a HCl treatment solution with a mass fraction of 1.0 mol / L for 1 hour, and weigh the mass fraction as HCl soaking. The 1.0% vinyl triethoxysilane coupling agent of the glass fiber, the weighed coupling agent was prepared into a 4% coupling agent solution, and then the glass fiber was soaked in the solution for 2 hours to make the silane coupling agent. The glass fiber is coated with the linking agent, and finally the treated glass fiber is placed in a 450 ℃ oven for constant temperature treatment for 4 hours, taken out and cooled at room temperature for 1 hour to obtain the modified glass fiber;

[0028] 2) Weigh the vinyl triethoxysilane coupling agent, the purity is 98%, the partic...

Embodiment 2

[0032] This example is the same as Example 1, the difference is that the heat treatment temperature of step (1) in the preparation method of the polymer-based PTC heating tape in this example is 450 ° C, the time is 1min, the HCl solution of the treatment liquid concentration 1.2mol / L is soaked The time is 1.5h, the step (2) melting inhibitor is 98% pure, the particle size distribution is 0.6μm, and the specific surface area is 4m 3 / g of ultrafine magnesium hydroxide.

[0033] After measuring for 30 minutes, it is determined that the starting current is 0.31A, and the heating temperature is 125°C.

Embodiment 3

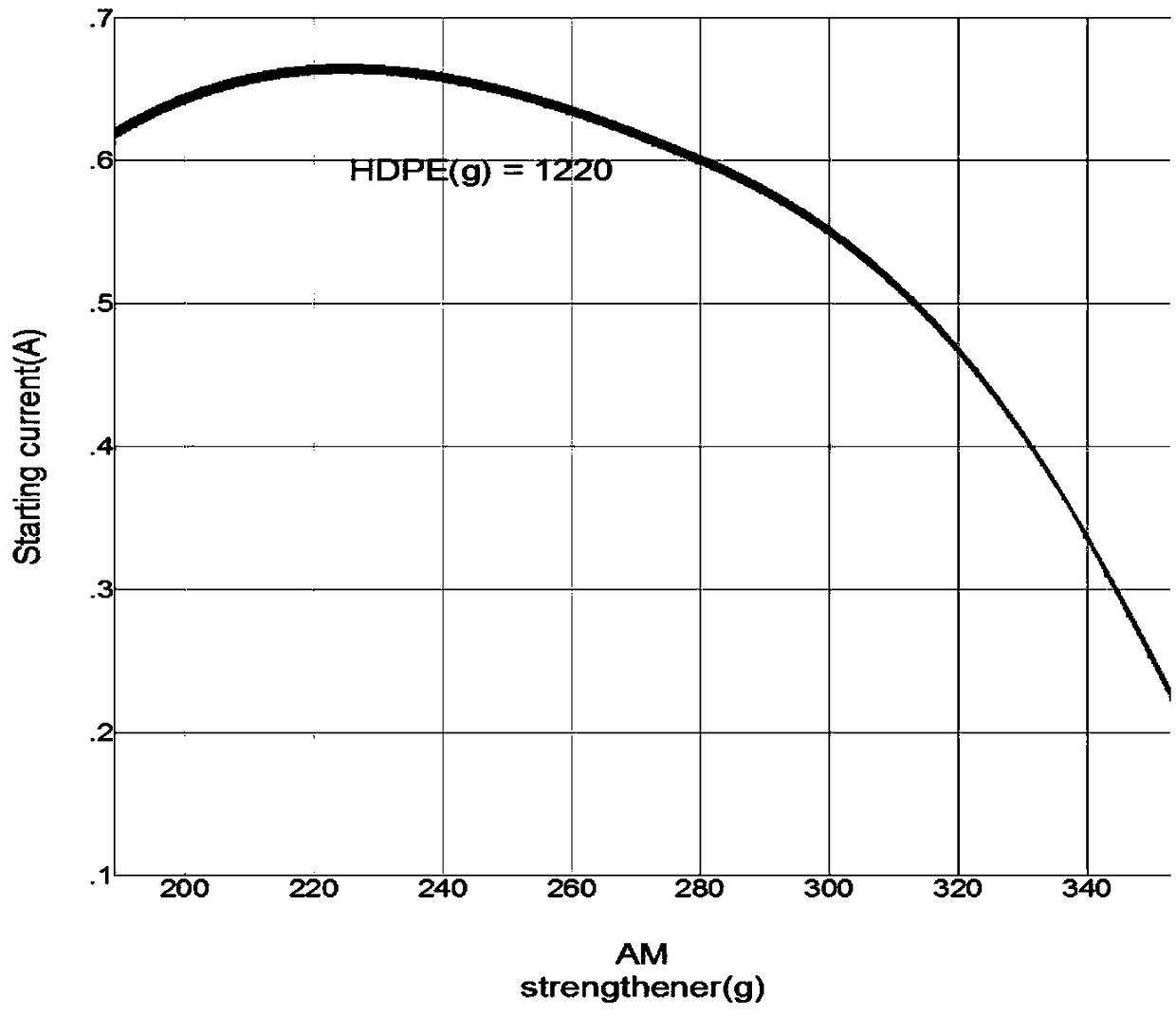

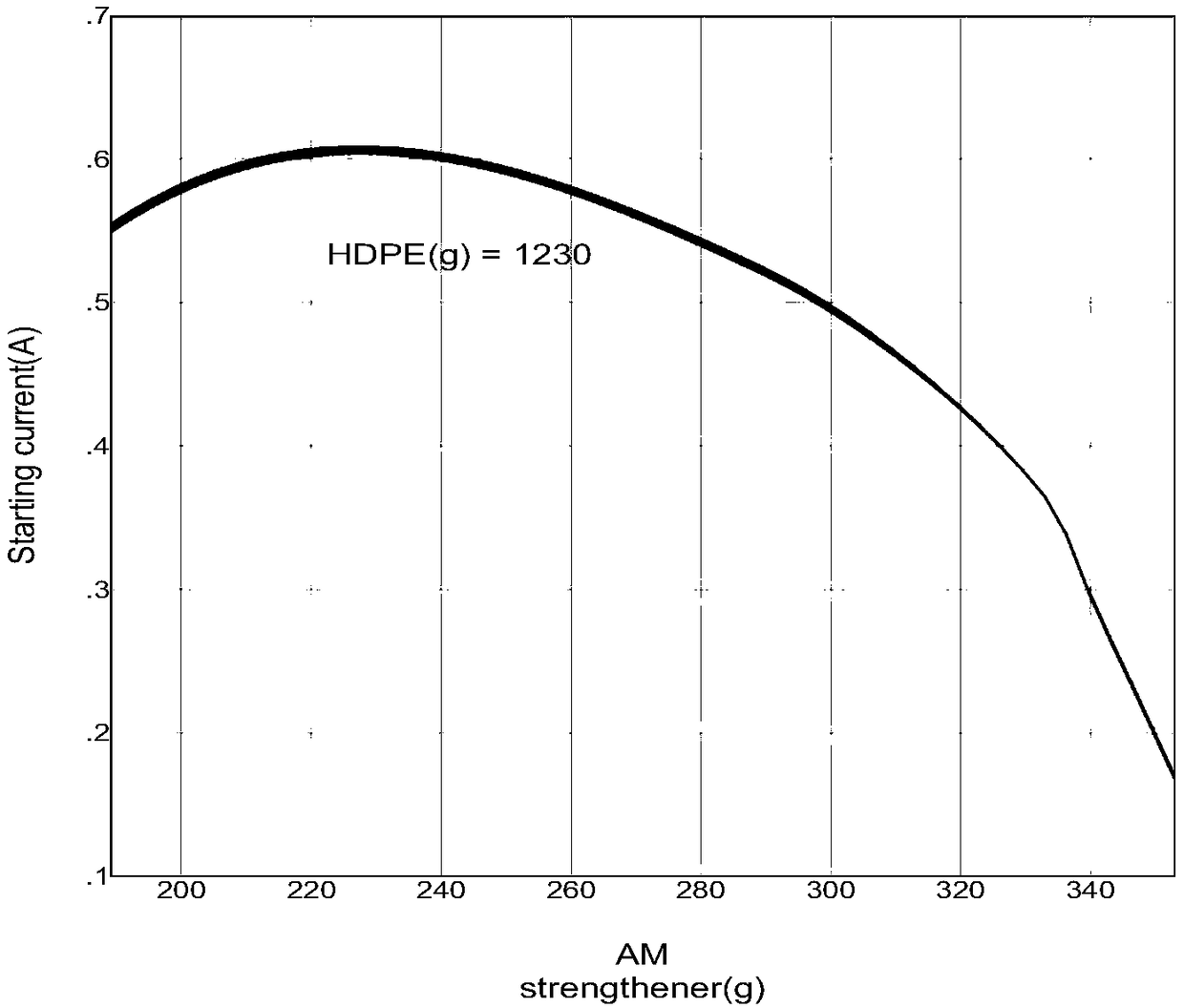

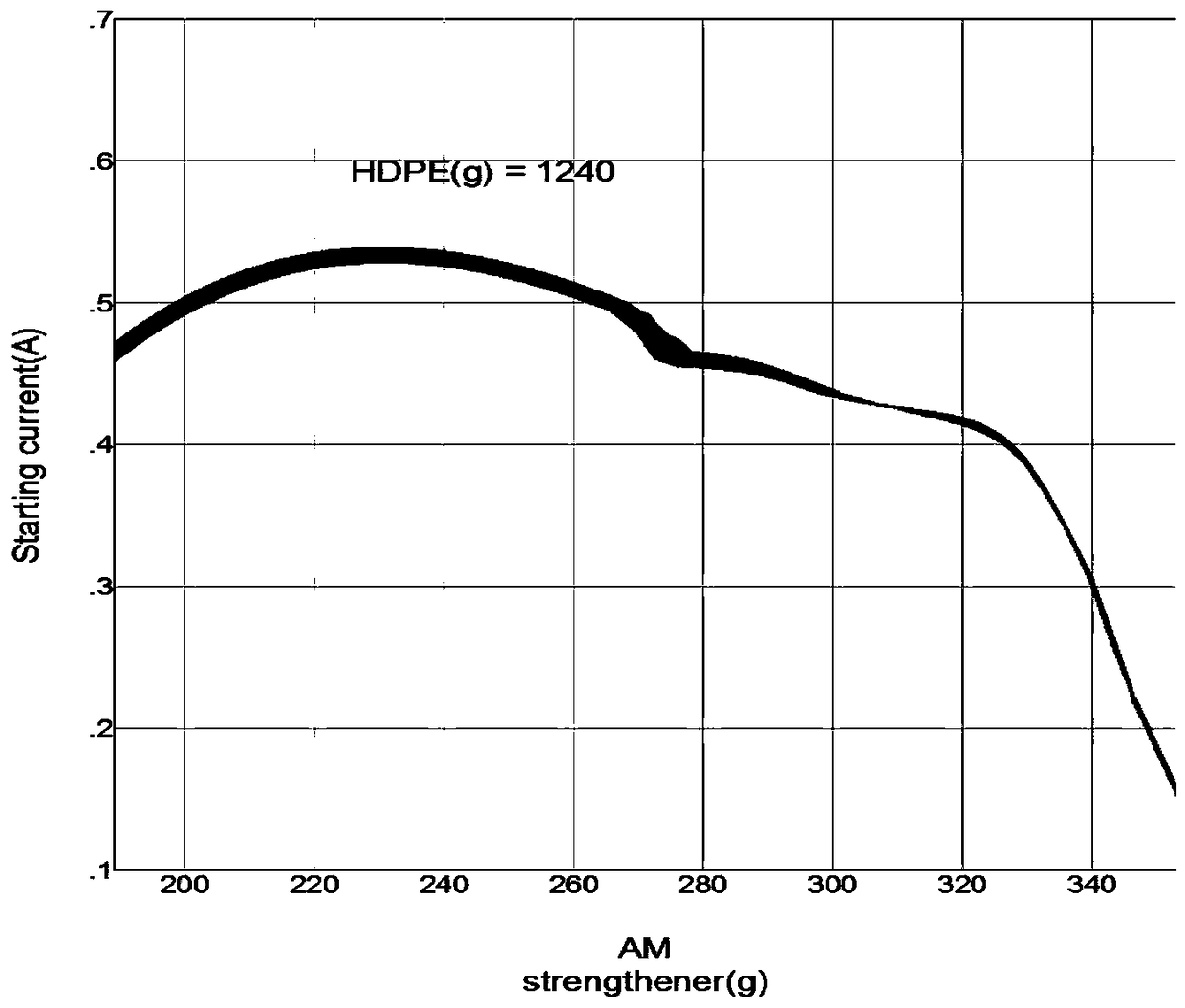

[0035] This example is the same as Example 1, except that in this example, 60 parts by weight of coupling agent, 323 parts by weight of melt inhibitor, 232 parts by weight of glass fiber, and 1255 parts by weight of matrix material HDPE-7000F are used as raw materials, and Example 1 is used. According to the preparation method in , the prepared copper core temperature heating tape sample is measured for 30 minutes and its starting current is 0.37A, and the heating temperature is 97°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com