TMCP type marine austenitic stainless steel composite plate and preparation method thereof

A technology of austenitic stainless steel and clad plate, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of influence of rolling power and complicated process, and achieve high rolling power and simple process. , reduce the effect of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

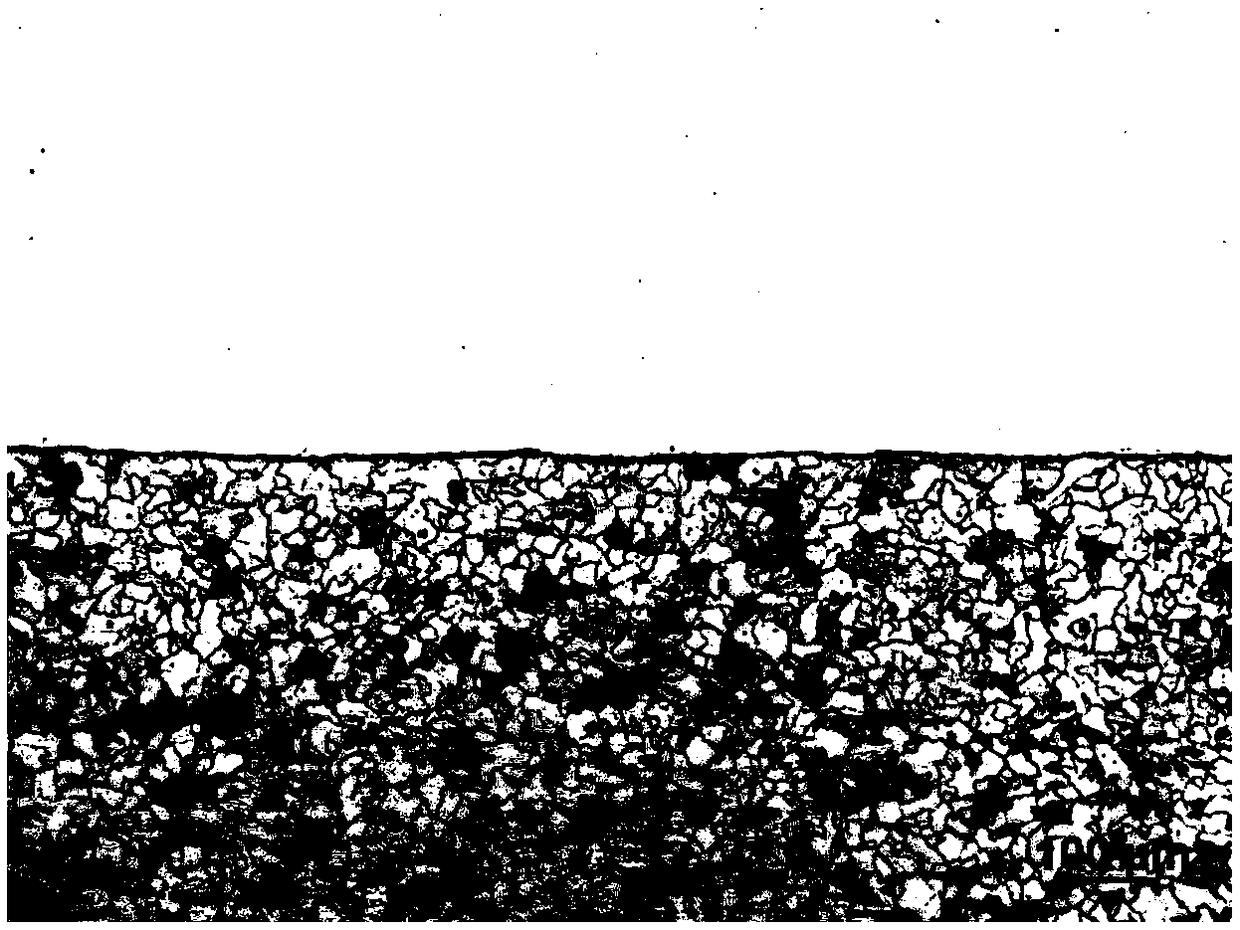

[0035] A TMCP type marine austenitic stainless steel clad plate and its preparation method provided in this embodiment, the blank structure is as follows figure 1 As shown, the details are as follows:

[0036] The DH32 steel type with a base material thickness of 102mm is selected, and the chemical composition is shown in Table 1. The composite material blank is selected from S31603 austenitic stainless steel with a thickness of 18mm, and the rolled finished product is S31603+DH32 composite plate with a thickness of 3+17mm.

[0037]One of the surfaces of the two DH32 base material blanks and the two S31603 composite material blanks was ground, so that the fresh metal was completely exposed on the surface. Apply silicone release agent or alumina / magnesia type release agent to the unpolished surface of the composite material, and dry the release agent at 550°C to 650°C. Spot-weld and fix the seals around the polished surface of one of the base materials. The seals are made of c...

Embodiment 2

[0041] A TMCP type marine austenitic stainless steel clad plate and its preparation method provided in this embodiment are as follows:

[0042] The DH36 steel type with a base material thickness of 60mm is selected, and the chemical composition is shown in Table 1. The composite material blank is S30403 austenitic stainless steel with a thickness of 12.5mm, and the rolled finished product is a S30403+DH36 composite plate with a thickness of 2.5+12mm.

[0043] One of the surfaces of two DH36 base material blanks and two S30403 composite material blanks was ground to expose the fresh metal completely. Apply silicone release agent or alumina / magnesia type release agent to the unpolished surface of the composite material, and dry the release agent at 550°C to 650°C. Spot-weld and fix the seals around the polished surface of one of the base materials. The seals are made of carbon steel; the non-composite surfaces of the two composite materials are superimposed and placed in the gro...

Embodiment 3

[0046] A TMCP type marine austenitic stainless steel clad plate and its preparation method provided in this embodiment are as follows:

[0047] The AH32 steel grade with a base material thickness of 82.5mm is selected. The chemical composition is shown in Table 1. The composite material blank is selected from S31703 austenitic stainless steel with a thickness of 16.5mm, and the rolled finished product is S31703+AH32 composite plate with a thickness of 3.0+15mm.

[0048] One of the surfaces of the two AH32 base material blanks and the two S30403 composite material blanks was ground so that the fresh metal was completely exposed on the surface. Apply silicone release agent or alumina / magnesia type release agent to the unpolished surface of the composite material, and dry the release agent at 550°C to 650°C. Spot-weld and fix the seals around the polished surface of one of the base materials. The seals are made of carbon steel; the non-composite surfaces of the two composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com