Laser processing equipment, three-dimensional antenna, processing method and communication equipment

A three-dimensional antenna, laser processing technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of low component flexibility, short preparation process, long preparation process, etc., to improve processing efficiency and improve processing accuracy , the effect of extending the connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

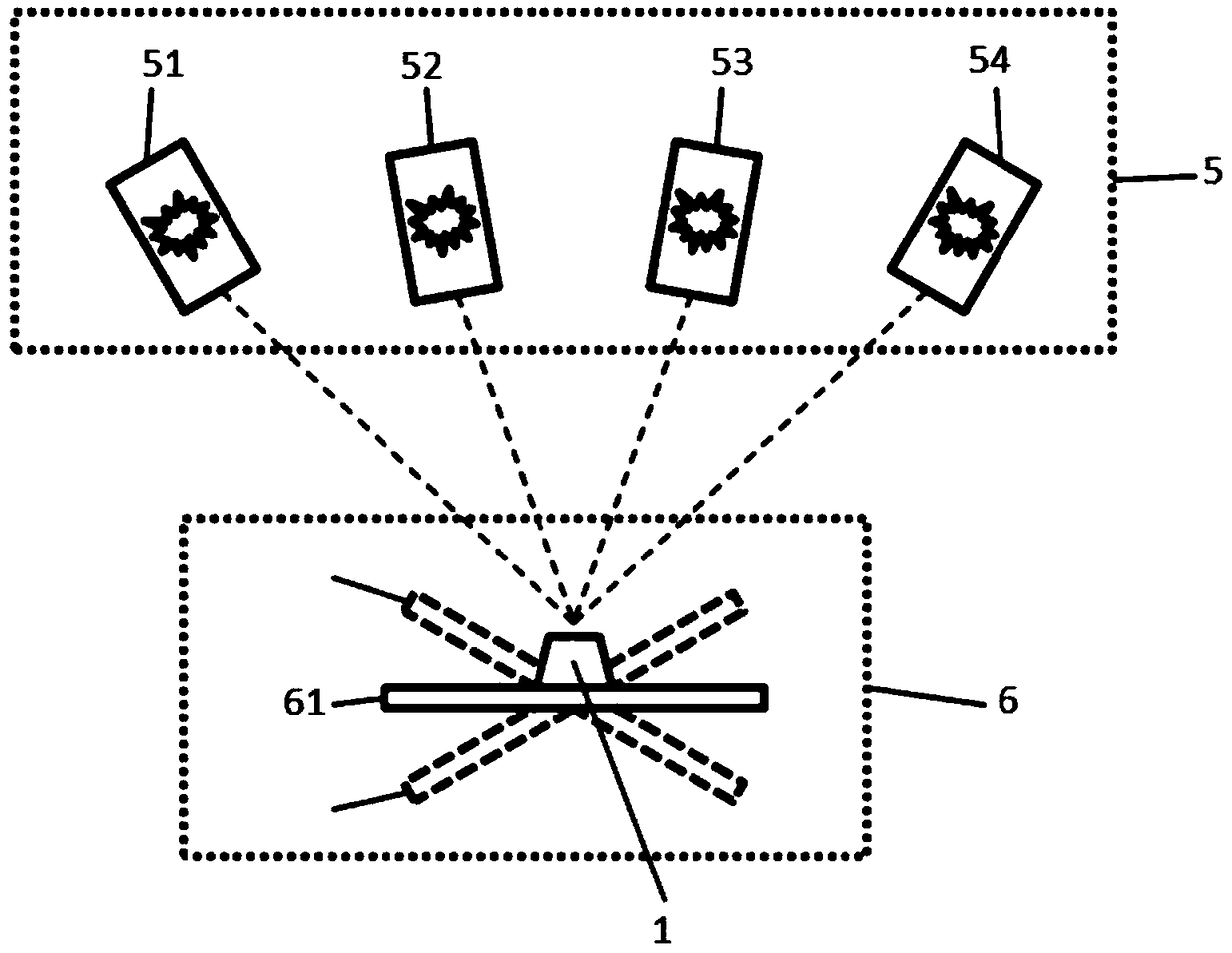

[0053] see figure 1 , a laser processing equipment for a three-dimensional antenna, comprising: a laser light source 5 for laser processing an insulating substrate 1 of a three-dimensional antenna to obtain a routing path of a metal circuit of the three-dimensional antenna; and a positioning unit 6 for Insulating base material 1 is positioned and fixed insulating base material 1; And the stereoscopic optical vision detection unit (not shown) that is used for positioning and detecting insulating base material 1; And the linearity that is used to adjust the position of insulating base material 1 motor (not shown in the figure); wherein, the number of laser light sources 5 is multiple; the positioning unit 6 has multiple switchable processing stations 61 , and the multiple processing stations 61 correspond to multiple laser light sources 5 .

[0054] The laser processing equipment of the three-dimensional antenna in the present embodiment includes a plurality of laser light sourc...

Embodiment 2

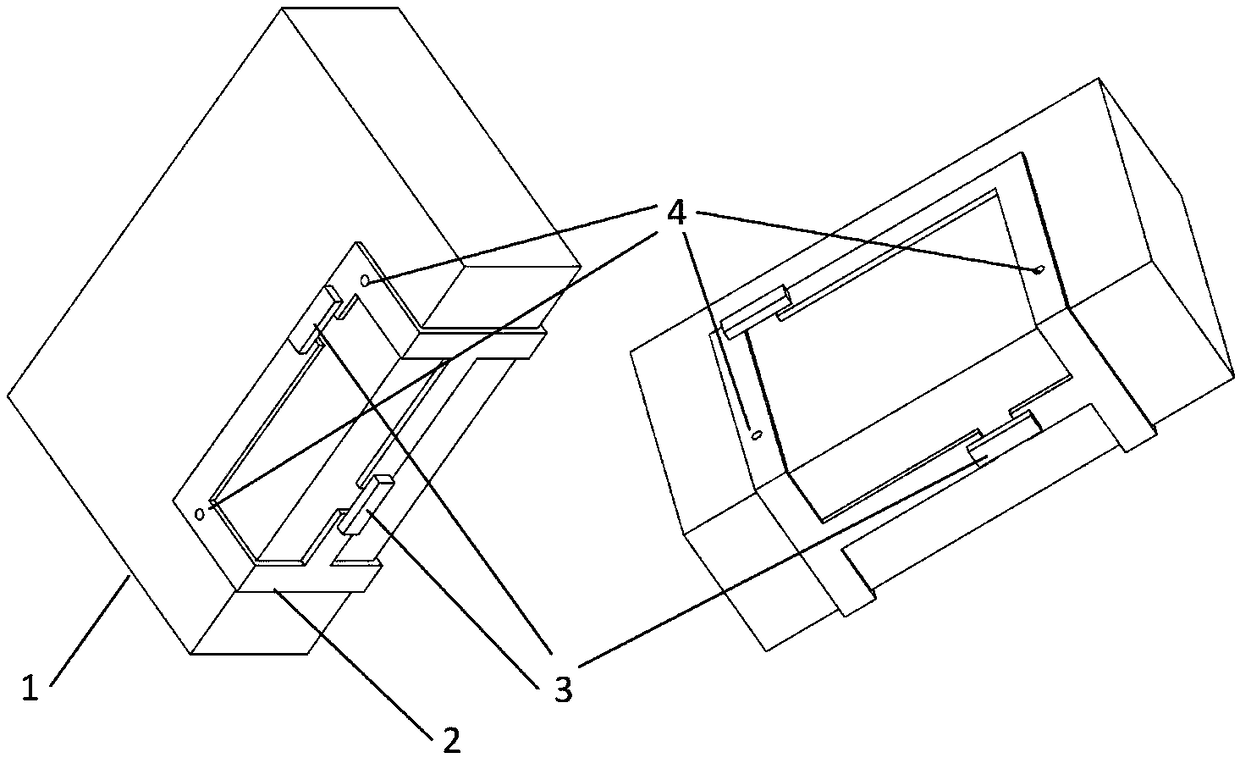

[0060] see figure 2 , a three-dimensional antenna, comprising: an insulating substrate 1, used to provide the stability of the overall structure of the three-dimensional antenna; several surface mount components 3, the surface mount components 3 are arranged on the outer surface of the insulating substrate 1; and metal circuits 2. The metal line 2 is arranged on the outer surface of the insulating substrate 1, and the metal line 2 is electrically connected to the surface mount component 3; wherein, the number of metallized via holes is one or more, and the diameter of the metallized via holes is less than 0.5 mm; the metal circuit 2 is directly formed on the insulating substrate 1 . The material of the metal circuit 1 can be any combination of copper and nickel, copper and silver, copper and nickel and gold, copper and nickel and tin.

[0061] In the three-dimensional antenna in this embodiment, the metal circuit 2 is directly formed on the insulating substrate 1, and the su...

Embodiment 3

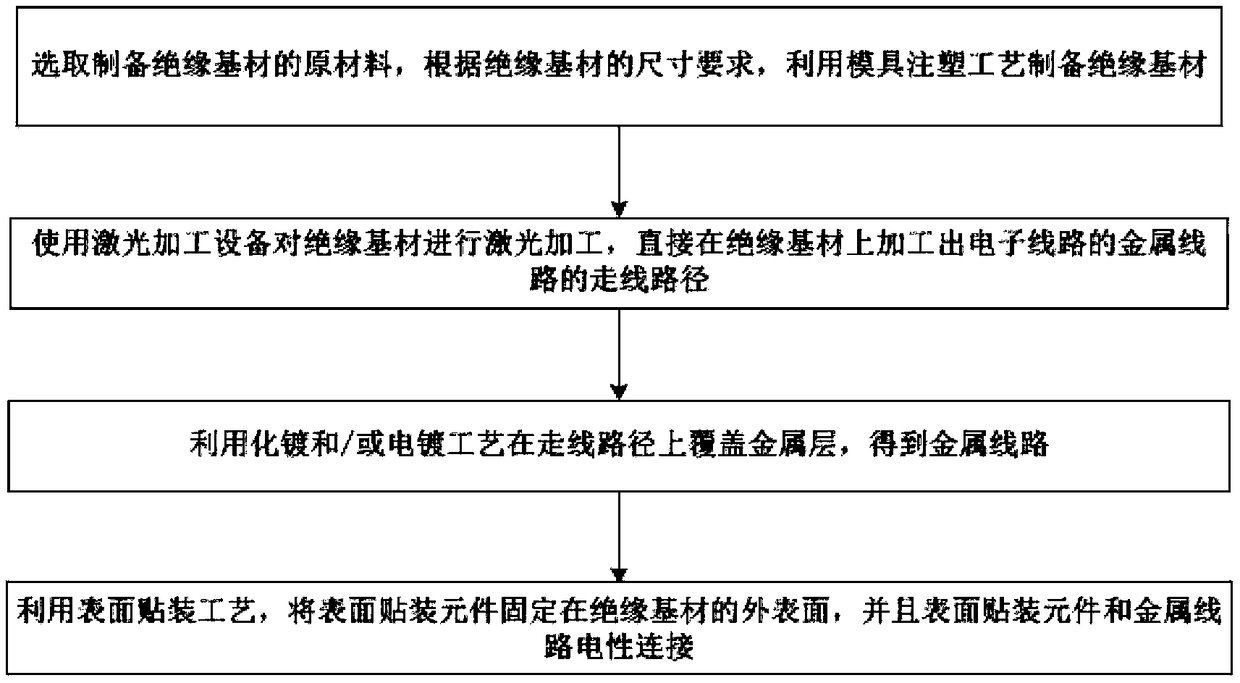

[0066] see image 3 , a processing method for a three-dimensional antenna, comprising: S1: selecting raw materials for preparing an insulating base material, and preparing the insulating base material by using a mold injection molding process according to the size requirements of the insulating base material; S2: using the laser of the three-dimensional antenna in Example 1 The processing equipment performs laser processing on the insulating substrate, and directly processes the routing path of the metal circuit of the three-dimensional antenna on the insulating substrate; S3: uses electroless plating and / or electroplating technology to cover the metal layer on the routing path to obtain a metal circuit ; S4: Using a surface mount process, the surface mount component is fixed on the outer surface of the insulating substrate, and the surface mount component is electrically connected to the metal circuit.

[0067] Specifically, step S2 includes a surface engraving process, an ed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com